3M Aluminum Oxide Sandpaper Sheets - 0.1 to 5mm 3 Bar Embossed Aluminum Sheet Five Bars Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Embossed aluminum sheet | |

Alloy grade | 1050,1060,1100,3003,3004,3105,5052,5005,5754,5083,6061,6063 etc |

Temper | 0,H12,H14,H16,H18,H22,H24,H26,H32,H34 |

Thickness | 0.8-12mm |

width | 10~1200mm |

length | 1000-10000mm |

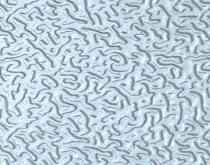

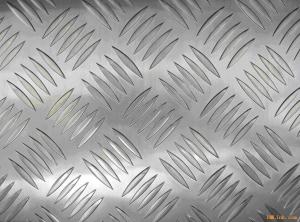

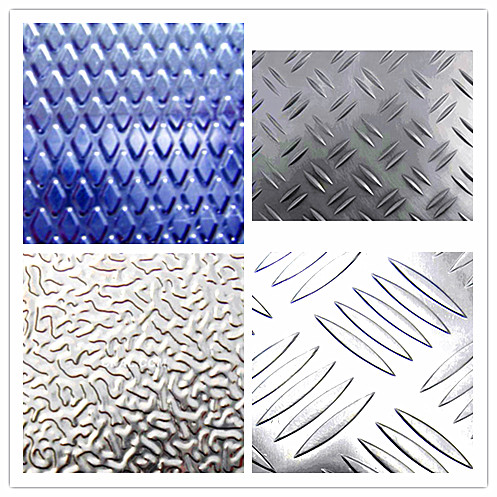

Decorative design | Five bars, classic stucco(orange peel), variation stucco, semi-circle, diamond ,three bars, two bars ,compass etc

|

Coating | PE and PVDF |

Application/use | Widely used in refrigeratory house ,floor, freight car, ship, compartment lamp, construction platform ,air conditioner ,lift for skid-resistance etc |

Quality certificate | ISO 9001-2008 ,SGS |

Technical standard | GB/T 3880 |

MOQ | 3-5 tons, negotiable |

Payment terms | T/T or L/C |

Delivery | About 20~25 days after receipt of deposit |

Package | Export standard package |

Kindly remind | Our machine can cut any size according to your requirement |

Pictures for embossed aluminum sheet

Application:

Widely used in refrigeratory house ,floor, freight car, ship, compartment lamp, construction platform ,air conditioner ,lift for skid-resistance etc

Packaging & Delivery

| Packaging Details: | Standard seaworthy exporting carton, Wooden pallets,waterproof paper and plastic coverage or or as per customer's requirements |

| Delivery Detail: | within 20~25days after receive advanced deposit |

- Q: What does aluminum plate mean?

- Dear, 1070 and 1060 are not the specifications of aluminum sheet, but the type of aluminum plateThe model is used to distinguish the different components of aluminum, the model is different, the composition of aluminum is differentShenzhen Cheng Cheng metal - - - --- aluminum plate - -

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 2, fluorocarbon spraying is a kind of electrostatic spraying, and liquid spraying methods, called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries.

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- There are several different types of surface treatments available for architectural aluminum sheets. These treatments are designed to enhance the appearance, durability, and performance of the aluminum, making it suitable for a wide range of architectural applications. One common type of surface treatment is anodizing. Anodizing involves immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed to achieve a desired color or left clear for a natural metallic appearance. Anodized aluminum sheets are known for their excellent corrosion resistance, scratch resistance, and color stability. Another type of surface treatment is powder coating. Powder coating involves applying a dry powder electrostatically to the aluminum sheet and then curing it in an oven. The powder melts and fuses to the surface, creating a smooth and durable finish. Powder coating provides excellent color retention, weather resistance, and resistance to chipping and cracking. A third type of surface treatment is PVDF coating. PVDF (polyvinylidene fluoride) coating is a high-performance fluoropolymer resin that is applied to the aluminum sheet through a coil coating process. PVDF coatings offer exceptional resistance to fading, chalking, and chemical attack, making them ideal for exterior applications where color retention and durability are key. Additionally, there are various mechanical surface treatments available for architectural aluminum sheets. These treatments, such as brushing or polishing, can provide a desired texture or reflectivity to the surface. Mechanical treatments can be used to create a brushed, satin, or mirror-like finish, adding aesthetic appeal to the aluminum sheet. In summary, the different types of surface treatments available for architectural aluminum sheets include anodizing, powder coating, PVDF coating, and mechanical treatments. Each treatment offers unique benefits and characteristics, allowing architects and designers to choose the most suitable option for their specific project requirements.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are highly suitable for signage applications due to their durability, lightweight nature, and ability to withstand various weather conditions. They are also easy to customize, making them a popular choice for both indoor and outdoor signage.

- Q: Can aluminum sheets be bent without cracking?

- Yes, aluminum sheets can be bent without cracking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and formed without breaking. However, the ability to bend aluminum sheets without cracking depends on several factors such as the thickness of the sheet, the type and grade of aluminum used, and the specific bending technique employed. It is important to use proper tools and techniques when bending aluminum to ensure that it remains intact and free from cracks.

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular material choice for HVAC applications due to its many advantageous properties. It is lightweight, making it easier to handle and install. Aluminum is also highly resistant to corrosion, which is crucial for HVAC systems that are exposed to moisture and varying temperatures. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This makes it ideal for heat exchangers and other components in HVAC systems. Overall, aluminum sheets are a reliable and durable option for HVAC systems.

- Q: How do aluminum sheets perform in high-temperature environments?

- Due to its exceptional thermal conductivity and relatively low melting point, aluminum sheets are highly effective in high-temperature conditions. With a melting point of 660.3°C (1220.5°F), aluminum is able to endure elevated temperatures without melting, unlike many other metals. Furthermore, its remarkable thermal conductivity enables efficient heat dissipation from the surface, preventing overheating and maintaining the integrity of structures. This quality makes aluminum sheets ideal for applications in industries such as aerospace, automotive, and construction, which often encounter high temperatures. However, it is crucial to acknowledge that prolonged exposure to extremely high temperatures can lead to a weakening of aluminum and a reduction in its mechanical properties. Consequently, in extreme high-temperature environments, it may be necessary to explore alternative materials or implement additional protective measures to ensure optimal performance.

- Q: Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It is commonly used in fencing applications due to its ability to withstand harsh weather conditions, including rain, snow, and UV rays. Aluminum sheets can be easily fabricated into different fence styles and designs, such as picket fences, privacy fences, or decorative fences. Additionally, aluminum fencing requires minimal maintenance as it does not rust or rot like other materials such as wood or iron. Overall, aluminum sheets provide an excellent option for fencing due to their strength, longevity, and aesthetic appeal.

- Q: What is the typical lead time for ordering aluminum sheets?

- The typical lead time for ordering aluminum sheets can vary depending on the supplier and specific requirements, but it usually ranges from a few days to a couple of weeks.

- Q: iron-based alloys over aluminum in structural members of bridges and buildings?

- Strength-to-weight ratio.

Send your message to us

3M Aluminum Oxide Sandpaper Sheets - 0.1 to 5mm 3 Bar Embossed Aluminum Sheet Five Bars Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords