Stainless Steel Slab And Sheet And Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

SS SHEET, SS PLATE, SS SLAB are our best-selling productions, with very cheapest price and of course best-quality. if you are interested in it, please feel free to contact me.

application: construction field and decoration field, etc. There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

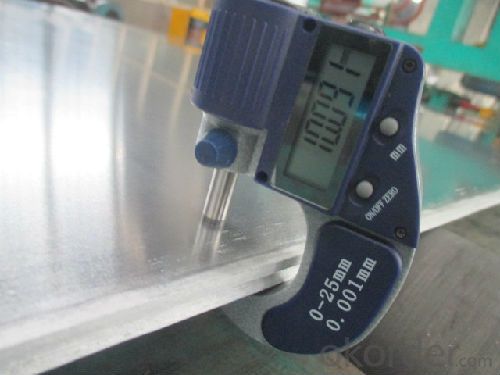

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What are the benefits of using textured stainless steel sheets?

- There are several benefits to using textured stainless steel sheets. Firstly, the textured surface of these sheets provides enhanced visual appeal and aesthetic value. The unique patterns and textures on the stainless steel sheets can add depth and dimension to any space, making it more visually interesting and appealing. This makes them a popular choice for architectural and interior design projects. Secondly, textured stainless steel sheets offer improved durability and resistance to wear and tear. The textured surface helps to hide scratches, fingerprints, and other imperfections that may occur over time, making the sheets look cleaner and more polished for longer periods. This makes them ideal for high-traffic areas or applications where aesthetics and durability are equally important. Additionally, using textured stainless steel sheets can provide better grip and traction. The raised patterns on the surface of the sheets can create a non-slip surface, making them suitable for applications where slip resistance is crucial, such as flooring, stairs, or ramps. This enhanced grip can also be advantageous in industrial or commercial settings where safety is a priority. Moreover, textured stainless steel sheets are relatively low-maintenance. The textured surface is less prone to showing dirt or smudges, which means less frequent cleaning or maintenance is required. This makes them a convenient choice for applications in busy environments or areas where regular cleaning may be challenging. Lastly, textured stainless steel sheets are highly versatile and can be used in a wide range of applications. From architectural and interior design projects to industrial and commercial settings, these sheets can be employed in various ways. They can be used for wall cladding, columns, decorative panels, countertops, furniture, and much more, offering endless possibilities for creative and functional design solutions. In summary, the benefits of using textured stainless steel sheets include enhanced visual appeal, improved durability, better grip and traction, low-maintenance requirements, and versatility in application. These sheets offer a combination of practical and aesthetic advantages, making them a popular choice for a variety of projects in different industries.

- Q: What are the benefits of using diamond plate stainless steel sheets?

- Diamond plate stainless steel sheets offer several benefits. Firstly, they provide exceptional durability due to their rugged diamond pattern, making them resistant to wear and tear. This makes them ideal for heavy-duty applications and high-traffic areas. Secondly, the raised diamond pattern enhances slip resistance, ensuring a safer working environment. Additionally, diamond plate stainless steel sheets are corrosion-resistant, making them suitable for outdoor or wet environments. They are also easy to clean and maintain, making them a practical choice for a variety of industries. Overall, their strength, durability, slip resistance, and corrosion resistance make diamond plate stainless steel sheets a reliable and long-lasting option.

- Q: Can stainless steel sheets be used for staircase railings?

- Certainly! Staircase railings can indeed utilize stainless steel sheets. Stainless steel stands out as a favored option for such railings owing to its exceptional durability, strength, and resistance against corrosion. By cutting, shaping, and welding stainless steel sheets, a multitude of railing designs and styles can be crafted. Additionally, these sheets can be finished in various manners, such as brushing or polishing, to achieve the desired aesthetic appeal. Not only do stainless steel railings offer an appealing appearance, but they also furnish a secure and robust support for staircases.

- Q: What are the different sheet sizes available for stainless steel?

- The different sheet sizes available for stainless steel vary depending on the manufacturer and specific requirements, but common sizes include 4x8 feet, 4x10 feet, and 5x10 feet.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To avoid the presence of fingerprints or smudges on stainless steel sheets, there are several simple steps that can be taken: 1. Regularly clean the surface: Regularly wiping the stainless steel sheets with a soft cloth or microfiber cloth can help prevent the accumulation of fingerprints and smudges. 2. Utilize mild soap and water: Create a mixture of warm water and a few drops of mild dish soap. Dip the cloth into this solution and gently wipe the stainless steel surface in the direction of the grain. This will eliminate any dirt or oil that may attract fingerprints. 3. Thoroughly dry: After cleaning, ensure that the stainless steel sheets are completely dry by using a clean, dry cloth. This will prevent the occurrence of water spots or streaks that can give the surface a smudged appearance. 4. Avoid abrasive cleaning agents or tools: Refrain from using harsh chemicals, abrasive cleaners, or scrub brushes as they can harm the stainless steel finish, making it more susceptible to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths in order to preserve the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Applying a stainless steel cleaner or polish can establish a protective barrier on the surface, rendering it more resistant to fingerprints and smudges. Adhere to the instructions provided with the product and use a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you are aware that your hands tend to leave fingerprints easily, it may be beneficial to wear gloves while handling stainless steel sheets. This precautionary measure can prevent direct contact with the surface and diminish the likelihood of leaving smudges. By adhering to these suggestions, the cleanliness and luster of your stainless steel sheets can be maintained, thereby preventing fingerprints and smudges from diminishing their appearance.

- Q: Are stainless steel sheets suitable for corrosive environments?

- Yes, stainless steel sheets are highly suitable for corrosive environments. This is because stainless steel contains alloying elements such as chromium, which forms a protective layer on the surface, preventing corrosion and rusting. Additionally, stainless steel has excellent resistance to a wide range of corrosive substances, making it ideal for various industries and applications where exposure to corrosive environments is common.

- Q: Are stainless steel sheets suitable for elevator flooring?

- Indeed, elevator flooring can be made of stainless steel sheets. The reason behind this preference is that stainless steel possesses durability and resistance against corrosion, rendering it an ideal selection for spaces with heavy foot traffic, such as elevator floors. It can endure substantial weights and is impervious to scratches, stains, and dents, guaranteeing a flooring solution that is both visually appealing and long-lasting. Furthermore, stainless steel is effortless to clean and maintain, thereby providing a hygienic alternative for elevator flooring.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Automotive grilles or trim can be effectively improved by using stainless steel sheets. This material is highly durable and resistant to corrosion, making it suitable for withstanding the challenging conditions found in the automotive environment. These conditions include exposure to moisture, road salt, and fluctuating temperatures. Stainless steel is also renowned for its strength, providing excellent protection to the front end of vehicles. What's more, stainless steel sheets can be easily shaped and molded into different designs and forms to meet the specific style requirements of automotive grilles or trim. Additionally, stainless steel possesses an attractive aesthetic appeal that can enhance the overall appearance of the vehicle. In summary, the utilization of stainless steel sheets for automotive grilles or trim guarantees long-lasting durability, functionality, and a refined look.

- Q: Are stainless steel sheets suitable for architectural facades?

- Yes, stainless steel sheets are suitable for architectural facades. They offer durability, corrosion resistance, and a sleek modern look that complements various architectural styles. Stainless steel sheets can withstand harsh weather conditions and require minimal maintenance, making them an excellent choice for long-lasting and visually appealing facades.

- Q: Can stainless steel sheets be used for chemical processing equipment?

- Yes, stainless steel sheets can be used for chemical processing equipment. Stainless steel is known for its corrosion resistance, making it suitable for handling various chemicals and acids. It also has excellent strength and durability, which makes it a reliable choice for chemical processing equipment that requires high performance and longevity.

Send your message to us

Stainless Steel Slab And Sheet And Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords