Marx Tinplate

Marx Tinplate Related Searches

Marx Tinplate Trains Tinplate Metal Tinplate Share Marklin Tinplate Printed Tinplate Tinplate China Tinplate Forum Tinplate Iron Tinplate Market Tata Tinplate Tinplate Sheets Tinplate Uk Tinplate Box Turkey Tinplate Tinplate Cover Tinplate Factory Tinplate Mailbox Buy Tinplate Tinplate Layout Tinplate Tins Nse Tinplate Stock Tinplate Tinplate Material Printing Tinplate Italy Tinplate Tinplate Products Tinplate Projects Thyssenkrupp Tinplate Mth Tinplate Rasselstein TinplateMarx Tinplate Supplier & Manufacturer from China

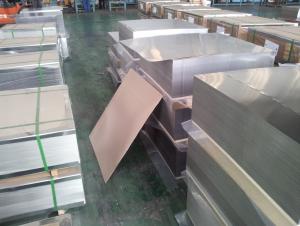

Marx Tinplate is a line of metal products known for their high-quality and versatile applications. These products are made from thin sheets of metal coated with tin, offering a range of benefits such as corrosion resistance and durability. The tinplate is widely used in various industries, including food packaging, automotive, and construction, where its strength and protective properties are highly valued. It is also utilized in the manufacturing of cans, containers, and other items that require a robust and reliable material. Okorder.com is a leading wholesale supplier of Marx Tinplate, boasting a vast inventory that caters to the diverse needs of customers across different sectors. With their extensive stock and commitment to quality, Okorder.com ensures that businesses have access to the Marx Tinplate products they require for their specific applications.Hot Products