Tin Free Steel and Tinplate for Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

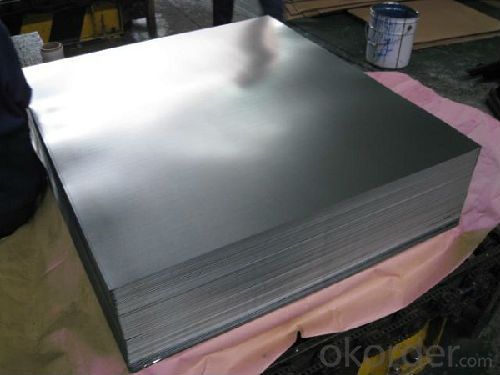

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What are the advantages of using tinplate for jewelry?

- One advantage of using tinplate for jewelry is its affordability. Tinplate is a cost-effective material compared to precious metals such as gold or silver, making it accessible to a wider range of consumers. Additionally, tinplate is lightweight, making it comfortable to wear for extended periods. It also offers versatility in design, allowing for intricate and detailed jewelry pieces. Lastly, tinplate is highly resistant to corrosion, ensuring the longevity and durability of the jewelry.

- Q: What are the main suppliers of tinplate?

- The main suppliers of tinplate are major steel manufacturers, such as ArcelorMittal, Nippon Steel Corporation, Tata Steel, and JFE Steel Corporation.

- Q: How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts by being a highly recyclable material. It can be used repeatedly without losing its properties, reducing the need for new resource extraction. Additionally, tinplate is commonly used for food and beverage packaging, which helps preserve products and reduces food waste. Its durability and corrosion resistance also extend the lifespan of products, making it a sustainable choice for various industries.

- Q: How does tinplate contribute to the aesthetics of furniture?

- Tinplate contributes to the aesthetics of furniture by adding a unique and visually appealing element. Its shiny and reflective surface can enhance the overall look of furniture, giving it a modern and stylish appearance. Additionally, tinplate can be easily customized and decorated with various patterns and colors, allowing for endless design possibilities and the creation of eye-catching furniture pieces.

- Q: What are the different types of tinplate seams?

- There are three main types of tinplate seams: the lap seam, the double seam, and the triple seam. The lap seam is formed by overlapping the tinplate and soldering the edges together. The double seam involves folding the edges of the tinplate over each other and then crimping them together. Lastly, the triple seam is created by folding the edges of the tinplate over each other twice and crimping them together.

- Q: How does tinplate packaging contribute to product reusability?

- Tinplate packaging contributes to product reusability by providing a durable and long-lasting solution. It can be easily cleaned and reused multiple times, reducing the need for single-use packaging. Additionally, tinplate packaging can protect the product from external factors, such as light, moisture, and air, which helps extend its shelf life, further enhancing reusability.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry as it provides a protective and durable coating for various products. It is often used to create cans and containers for food, beverages, and other consumer goods. Tinplate ensures the preservation of the contents, prevents contamination, and extends shelf life. Additionally, its versatility allows for easy printing and labeling, making it an ideal choice for branding and marketing purposes.

- Q: Can tinplate be used for packaging electronic components?

- Yes, tinplate can be used for packaging electronic components as it provides excellent protection against corrosion, offers good electrical conductivity, and is easy to shape into various packaging forms.

- Q: How does tinplate compare to aluminum in terms of properties and applications?

- Tinplate and aluminum have distinct properties and applications. Tinplate is steel coated with a thin layer of tin, making it corrosion-resistant, ductile, and easily solderable. It is commonly used for food and beverage packaging, as well as in construction and automotive industries. On the other hand, aluminum is lightweight, non-corrosive, and possesses high thermal and electrical conductivity. It finds extensive use in aerospace, electrical, and packaging industries due to its strength and recyclability. While tinplate offers better barrier properties, aluminum excels in weight reduction and energy efficiency. Hence, the choice between the two depends on specific needs and requirements.

- Q: Can tinplate be used for signage and displays?

- Yes, tinplate can certainly be used for signage and displays. Tinplate is a versatile material that offers durability, strength, and a smooth surface for printing or painting. It can be easily shaped, cut, and formed to create various signage and display options, making it a popular choice for indoor and outdoor applications. Additionally, tinplate is resistant to corrosion, making it suitable for long-lasting and weather-resistant signage and displays.

Send your message to us

Tin Free Steel and Tinplate for Prime Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords