Electric Tinplate coil and sheet for Chemical cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

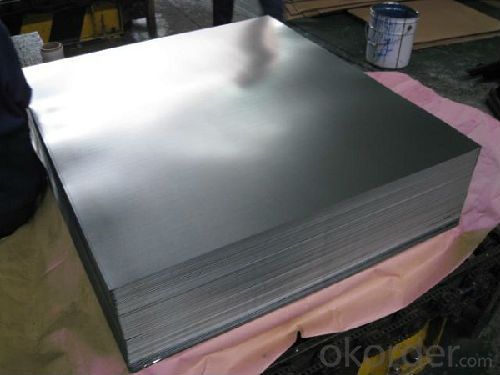

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: How does tinplate perform in terms of tamper-evident features?

- Tinplate performs exceptionally well in terms of tamper-evident features. Its inherent strength and durability make it difficult to tamper with or manipulate without leaving clear signs of tampering. Additionally, tinplate can be customized with various tamper-evident mechanisms such as seals, closures, or indicators, further enhancing its reliability as a tamper-evident packaging material.

- Q: Is tinplate resistant to corrosion?

- Yes, tinplate is highly resistant to corrosion due to the protective layer of tin that is electroplated onto the surface of the steel.

- Q: What are the quality control measures for tinplate production?

- Quality control measures for tinplate production typically involve several steps to ensure the production of high-quality tinplate. These measures may include thorough inspection of raw materials, such as tin-coated steel coils, to ensure they meet the required specifications. During the manufacturing process, regular testing and monitoring of various parameters like coating thickness, adhesion, surface finish, and tinplate dimensions are conducted. Additionally, visual inspections are performed to identify any defects or imperfections. Furthermore, samples are taken at different stages of production for laboratory testing, which may include corrosion resistance, mechanical properties, and chemical composition analysis. These measures help maintain consistent quality and ensure that the tinplate meets the necessary standards for its intended applications.

- Q: How is tinplate recycled?

- Tinplate is recycled by first collecting it from various sources, such as food cans or packaging materials. The collected tinplate is then sorted and separated from other materials like paper or plastic through a magnetic separation process. After this, the tinplate is shredded into small pieces and further sorted to remove any remaining impurities. The clean tinplate pieces are then melted in a furnace to separate the tin coating from the steel base. The separated tin and steel are both recycled separately, with the tin used for various purposes like coating new tinplate or producing solder, while the steel is reused for manufacturing other steel products. Overall, the recycling process of tinplate helps conserve resources, reduces waste, and promotes environmental sustainability.

- Q: What are the different ways to customize tinplate packaging?

- There are several ways to customize tinplate packaging. Some common methods include printing or embossing designs or logos directly onto the tinplate, applying decals or labels, using different colors or finishes, adding metallic or matte effects, and incorporating additional elements like windows or handles. These customization options allow businesses to create unique and visually appealing tinplate packaging that aligns with their brand identity and stands out on the shelves.

- Q: What are the main challenges in recycling tinplate?

- One of the main challenges in recycling tinplate is the separation of tin from steel. Tinplate is a combination of steel coated with a thin layer of tin, which provides corrosion resistance. However, separating these two materials during the recycling process can be costly and technically complex. Additionally, tinplate often contains various contaminants, such as paints, coatings, and labels, which need to be removed before recycling. Ensuring the proper collection and sorting of tinplate waste is another significant challenge as it requires educating the public about the importance of recycling and providing convenient recycling infrastructure.

- Q: Tin cans in what way sterilization good ah

- Water spray sterilization: this approach is the use of spray nozzle or tube hot water to the food, sterilization process is based on tinplate surface ends protruding, must exert anti pressure, especially for higher temperature sterilization of canned meat

- Q: What are the advantages of using tinplate for stationery and office supplies?

- One advantage of using tinplate for stationery and office supplies is its durability. Tinplate is highly resistant to corrosion and is less likely to get damaged or dented, ensuring that the supplies made from it will last longer. Additionally, tinplate has a smooth surface, making it easy to clean and maintain. Another advantage is its aesthetic appeal. Tinplate can be easily customized and printed on, allowing for creative and visually appealing designs on stationery and office supplies. Lastly, tinplate is also eco-friendly as it is a recyclable material, contributing to a more sustainable approach in the production and use of these supplies.

- Q: How does tinplate perform in terms of light blocking properties?

- Tinplate is known to provide excellent light blocking properties due to its opaque and reflective nature, making it an effective choice for packaging materials to prevent light exposure and preserve the quality of light-sensitive products.

- Q: What are the recycling processes for tinplate?

- The recycling processes for tinplate typically involve collecting and sorting the tinplate materials, removing any contaminants, such as paper or plastic coatings, and then shredding the tinplate into small pieces. The shredded tinplate is then melted in a furnace to separate the steel from the tin. The steel is recovered and can be used to make new tinplate products, while the tin is commonly reused in various applications or sold as a raw material.

Send your message to us

Electric Tinplate coil and sheet for Chemical cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords