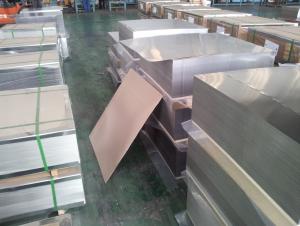

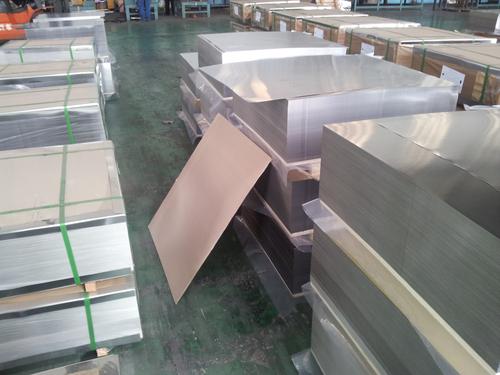

Tinplate for Metal container

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our Tinplates Specification is as below:

Standard: ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width and Length: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Tincoating:customized

Both Prime and Secondary Quality are available!!!

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13 mm to 0.49 mm.

- Q: How does tinplate perform in terms of light protection?

- Tinplate performs fairly well in terms of light protection. Its metal composition provides a good barrier against light, preventing the penetration of UV rays and reducing the risk of light-induced degradation or spoilage of the contents. However, its light protection capabilities may vary depending on the thickness and quality of the tin coating applied to the steel substrate.

- Q: Cookies with tinplate packaging has what advantage?

- Barrier: tinplate cans have excellent barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: Can tinplate be used for packaging of corrosive substances?

- No, tinplate is not suitable for packaging corrosive substances as it can react with the corrosive materials and corrode, leading to potential contamination and compromised packaging integrity.

- Q: Does tinplate require any specific handling or storage conditions?

- Yes, tinplate does require specific handling and storage conditions. It should be stored in a dry and well-ventilated area to prevent corrosion. It is also important to handle tinplate with care to avoid any scratches or dents that may compromise its protective coating.

- Q: What are the main trends in tinplate packaging?

- Some of the main trends in tinplate packaging include the increasing demand for sustainable and eco-friendly packaging solutions, the rise of convenient and innovative packaging designs, and the incorporation of advanced technologies for improved product protection and preservation. Additionally, there is a growing preference for personalized and customized tinplate packaging to enhance brand identity and consumer engagement.

- Q: What are the advantages of using tinplate for automotive components?

- One advantage of using tinplate for automotive components is its high corrosion resistance. Tinplate is coated with a thin layer of tin, which acts as a protective barrier against moisture and oxidation, ensuring the longevity of the components. Additionally, tinplate offers excellent formability, allowing for complex shapes and designs, which is crucial in the automotive industry. Lastly, tinplate is lightweight yet strong, contributing to improved fuel efficiency and overall vehicle performance.

- Q: Who can tell me how to adjust the roller seal defects?

- In the sealing device, the roll sealing roller, the upper pressure head tray, usually referred to as sealing three elements. The correct groove shape of the roller, the reasonable position of the head and the proper driving force of the tray support are the necessary conditions to ensure the normal roll sealing. (see Fig. 1) it is easy to see that the three elements of the seal are the basic components of the sealing device and are also a fundamental factor affecting the double hemming.

- Q: Can tinplate be used for packaging of non-food products?

- Yes, tinplate can be used for packaging of non-food products. Tinplate is a versatile material that offers excellent durability and corrosion resistance, making it suitable for a wide range of packaging applications including cosmetics, chemicals, and industrial products.

- Q: How does tinplate packaging contribute to product protection against oxidation?

- Tinplate packaging provides a protective barrier against oxidation due to its inherent properties. The tin coating on the steel surface acts as a barrier, preventing oxygen from coming into direct contact with the product inside the packaging. This barrier effectively slows down or prevents the oxidation process, preserving the quality and shelf-life of the product. Additionally, tinplate packaging is resistant to corrosion, ensuring the integrity of the package and further safeguarding against oxidation.

Send your message to us

Tinplate for Metal container

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords