Tinplate for metal packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

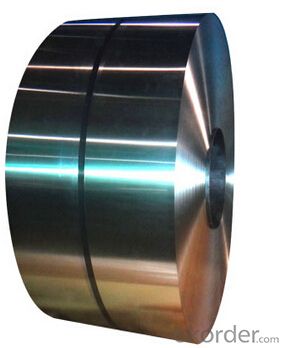

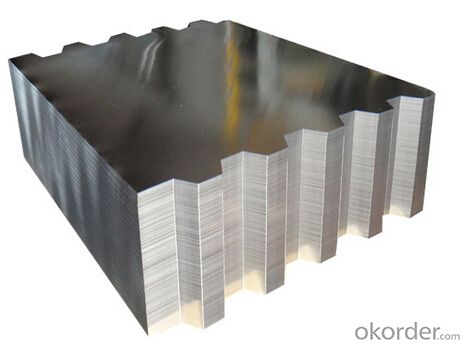

We are one of the main producers in China for tinplate. At present, our productivity is about 450000 MT/year. Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

The main product tinplate and tin free steel are metal package material widely used in food, light industry and chemical industry. We organize our production strictly in accordance with Q/ZYB E1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalent standards. Companies adhere to principles of quality, food safety, environment, occupation, health safety and energy, say "excellent quality to win the trust of customers, health and safety to gain the trust of the public, clean environment to harvest the trust of the community, safety and health to convince employees and energy-saving to be trusted by public". We are enjoying the trust and good name regarding to the superior quality and prefer service among the customers. Our products are sold nearly 150 enterprises including Europe, America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism running good. After years of effort, base on the introduction, absorption, digestion of the advanced technology, techniques, equipment, we gradually set up the unique production process and technical support system which is market need-oriental and suite to the Chinese condition. In the fierce market competition, our company will continue to pursue the excellence quality and outstanding service, and provide more and better service and service to meet customers demand on metal package home and abroad.

- Q: What are the regulations regarding tinplate packaging?

- The regulations regarding tinplate packaging vary depending on the country or region. However, in general, tinplate packaging must comply with certain standards to ensure its safety and suitability for use. These standards may include specifications for the tinplate material, its thickness, coating composition, and overall quality. Additionally, regulations often exist concerning labeling requirements, such as providing accurate information about the contents, proper handling instructions, and any necessary warnings. It is essential for manufacturers and suppliers to stay updated on the specific regulations applicable to their respective markets to ensure compliance and consumer safety.

- Q: How is tinplate coated for toys and games?

- Tinplate is commonly coated for toys and games using a process called electroplating, where a thin layer of tin is applied to the surface of the metal. This coating provides a protective barrier against corrosion and enhances the aesthetics of the toys and games.

- Q: What are the main countries producing tinplate?

- The main countries producing tinplate are China, Japan, and the United States.

- Q: What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products vary depending on their purpose and industry. However, some commonly seen sizes include cans ranging from small containers for food and beverages (such as soda cans) to larger ones for bulk products (such as paint cans). Tinplate products also come in various shapes, including rectangular, cylindrical, and irregular forms, to cater to different packaging needs and maximize storage efficiency.

- Q: How is tinplate affected by exposure to chemicals?

- Tinplate is generally resistant to chemical exposure, making it a suitable material for packaging and storage of various products. However, certain aggressive chemicals or strong acids can corrode the tinplate coating over time, potentially compromising the integrity of the container or affecting the quality of the contents. It is important to consider the specific chemicals involved and their concentration when assessing the potential effects on tinplate.

- Q: What are the factors that determine the lifespan of tinplate packaging?

- The factors that determine the lifespan of tinplate packaging include the quality of the tin coating, the thickness of the tinplate, the presence of protective coatings or lacquers, the environmental conditions in which the packaging is stored or used, and the handling or storage practices.

- Q: What about tin cans?

- Galvanized iron: galvanized iron for daily use, such as box, water pipe, etc.Tin: tin plated iron. Usually used for food packaging. Such as canned goods

- Q: What are the different forms and shapes tinplate can be manufactured into?

- Tinplate can be manufactured into various forms and shapes, including cans, containers, boxes, trays, and even decorative items. Its malleability allows for complex designs, making it suitable for a wide range of applications in the packaging industry.

- Q: How does tinplate contribute to the overall aesthetics of packaging?

- Tinplate contributes to the overall aesthetics of packaging by providing a sleek and shiny appearance. Its smooth surface allows for vibrant and high-quality printing, enhancing the visual appeal of the packaging. Additionally, tinplate's durability and ability to maintain its shape and color over time add to the overall attractiveness of the packaging, making it eye-catching and desirable to consumers.

- Q: How does tinplate packaging contribute to product freshness?

- Tinplate packaging contributes to product freshness by providing a protective barrier against external factors such as air, moisture, and light. This helps to prevent oxidation and preserve the quality, taste, and aroma of the packaged product. Additionally, tinplate packaging has excellent sealing properties, ensuring that the contents remain airtight and free from contamination, thereby extending the shelf life and maintaining product freshness.

Send your message to us

Tinplate for metal packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords