Electric Tinplate coil and sheet and Tin Free Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

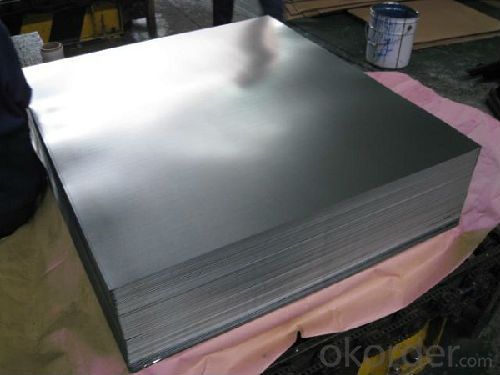

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. Generally, these canned goods have a shelf life of 2 to 5 years when stored in a cool, dry, and dark place. However, it is recommended to check the expiration date on the can and discard any cans that are bulging, leaking, or have a foul odor as they may be spoiled.

- Q: What are the environmental impacts of tinplate production?

- Tinplate production has several environmental impacts. Firstly, the extraction of tin ore can lead to deforestation and habitat destruction. Secondly, the smelting process releases greenhouse gases, contributing to climate change. Additionally, the use of chemicals and energy during manufacturing can result in air and water pollution. Lastly, the disposal of waste materials, such as slag and wastewater, can contaminate nearby ecosystems. Overall, tinplate production has significant environmental consequences that need to be addressed and mitigated.

- Q: Are there any health concerns associated with tinplate packaging?

- Yes, there are potential health concerns associated with tinplate packaging. Tinplate packaging can sometimes contain small amounts of lead, which is a toxic heavy metal. If the lead leaches into the food or beverage stored in the tinplate packaging, it can pose a health risk, especially in high quantities or with prolonged exposure. Additionally, some tinplate packaging may be lined with a plastic coating that contains harmful chemicals like BPA (bisphenol A) or phthalates, which can also leach into the food or beverage and have adverse health effects. It is important to check the safety of tinplate packaging and ensure it meets regulatory standards to minimize these health concerns.

- Q: What are the main competitors of tinplate in the packaging industry?

- The main competitors of tinplate in the packaging industry include aluminum, plastic, and glass.

- Q: What are the different types of tinplate closures available?

- Some of the different types of tinplate closures available include twist-off caps, lug caps, crown caps, and press-on caps.

- Q: Can tinplate packaging be used for cosmetic products?

- Yes, tinplate packaging can be used for cosmetic products. Tinplate is a popular choice for packaging cosmetics due to its durability, versatility, and ability to protect the products from external factors such as moisture and light. Additionally, tinplate packaging can be easily customized and decorated, allowing for attractive and eye-catching designs to enhance the brand image of cosmetic products.

- Q: How is tinplate coated for aerosol cans?

- Tinplate is coated for aerosol cans through a process called electrolytic tin coating. In this process, a thin layer of tin is deposited onto the surface of the tinplate by immersing it in a bath of tin solution. The tin coating provides a protective barrier against corrosion and ensures the cans remain durable and airtight.

- Q: Can tinplate be used for packaging fragile items?

- Yes, tinplate can be used for packaging fragile items. Tinplate is a strong and durable material that provides excellent protection against damage. Its resistance to impact and ability to withstand pressure make it suitable for packaging fragile items safely. Additionally, tinplate's ability to resist corrosion ensures that the packaging remains intact and protects the fragile items throughout the shipping or storage process.

- Q: Can tinplate be used for art and sculptures?

- Yes, tinplate can be used for art and sculptures. Its malleability and durability make it a suitable material for creating various artistic forms and sculptures.

- Q: How does tinplate compare to other packaging materials in terms of recyclability?

- Tinplate is highly recyclable and often considered to be one of the most sustainable packaging materials available. It can be easily separated from other materials during the recycling process and has a high recycling rate, making it a preferred choice for environmentally conscious consumers and industries.

Send your message to us

Electric Tinplate coil and sheet and Tin Free Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords