Tinplate Sheets For Tomato Paste Can, Double Reduced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Brief Introduction about our company

Our company is one largest state owned company and one largest tinplate supplier in China. Our annual output reaches more than 500,000 tons, both BA & CA, SR&DR. Now we have more than 10 overseas warehouses in the world, such as UAE, Saudi Arabia etc.

2. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

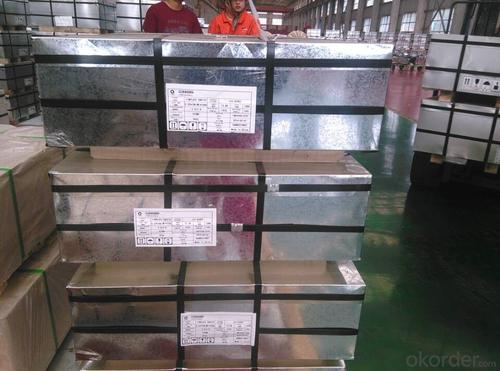

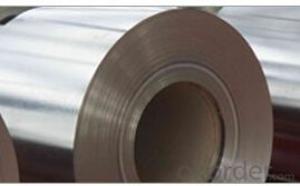

3. Our factory photo & equipments

4. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

5. FAQ

a. what’s your company name?

our company named CNBM international corporation, we are both one large state owned company and tinplate supplier in China

b. where your mill situated?

Our head office is in Beijing, while our mill in Hebei province.

c. how about the delivery time?

usually 55~65 days after receipt advance payment or original LC;

d. what payment term you accept?

Our payment term is very feasible, such as TT, DP, LC at sight, LC after sight etc.

e. can you offer MTC?

Of course, we will issue MTC after each shipment, for customer reference and testing if some quality issue appears.

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. Generally, these canned goods have a shelf life of 2 to 5 years when stored in a cool, dry, and dark place. However, it is recommended to check the expiration date on the can and discard any cans that are bulging, leaking, or have a foul odor as they may be spoiled.

- Q: How does tinplate perform in terms of UV resistance?

- Tinplate generally has poor UV resistance, meaning it is not highly resistant to the damaging effects of ultraviolet radiation.

- Q: What are the benefits of using tinplate for pharmaceuticals?

- There are several benefits of using tinplate for pharmaceuticals. Firstly, tinplate is highly resistant to corrosion, ensuring the integrity and safety of the pharmaceutical products. Secondly, tinplate provides a reliable barrier against moisture, oxygen, and light, thereby preserving the quality and extending the shelf life of the medications. Additionally, tinplate is a sustainable packaging material that is easily recyclable, reducing the environmental impact of pharmaceutical packaging. Lastly, tinplate is lightweight and durable, making it convenient for transportation and storage of pharmaceutical products.

- Q: Can tinplate packaging be used for sports equipment?

- Yes, tinplate packaging can be used for sports equipment. Tinplate is a durable and versatile material that can provide protection and longevity to various products, including sports equipment. It offers excellent resistance to corrosion and can withstand impact, making it suitable for packaging items like bats, balls, and other sports gear. Additionally, tinplate can be customized with attractive designs and branding, enhancing the overall presentation of the products.

- Q: What are the different sizes and shapes of tinplate packaging available?

- There are various sizes and shapes of tinplate packaging available, ranging from small tins for individual items such as lip balm or mints, to larger tins for products like cookies or tea. The shapes can also vary, including round, rectangular, or square tins, as well as specialty shapes like heart or star-shaped tins.

- Q: How does tinplate contribute to the convenience of pet care products?

- Tinplate contributes to the convenience of pet care products by providing a durable and lightweight packaging option that helps preserve the quality and freshness of the products. It is also easily recyclable, ensuring sustainability while offering a convenient solution for pet owners.

- Q: What are the main applications of tinplate in the jewelry industry?

- The main applications of tinplate in the jewelry industry include the production of tin-plated jewelry components such as clasps, findings, and beads. Tinplate is also utilized for decorative purposes, adding a shiny and lustrous finish to jewelry pieces.

- Q: What are the different methods of storing tinplate packaging?

- There are several methods of storing tinplate packaging, including stacking them on shelves or pallets, using storage bins or containers, hanging them on racks or hooks, or utilizing specialized storage systems such as gravity flow or carousel systems. The choice of method depends on factors such as available space, the quantity of packaging, ease of access, and the specific requirements of the packaging material.

- Q: Can tinplate be used for ammunition?

- Yes, tinplate can be used for ammunition. It is commonly used for manufacturing shotgun shells and some types of bullet casings due to its durability and ability to withstand high pressures.

- Q: What are the different ways to stack tinplate cans?

- There are several different ways to stack tinplate cans, including vertically, horizontally, in a pyramid formation, or in a grid pattern. The choice of stacking method may depend on factors such as available space, stability required, or ease of access.

Send your message to us

Tinplate Sheets For Tomato Paste Can, Double Reduced

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords