Tinplate for Metal Tin Containers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

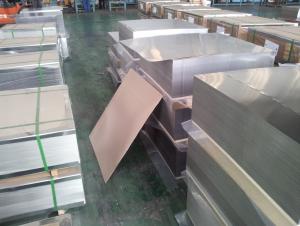

Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Our Tinplates Specification is as below:

Standard: ISO 11949 -1995, JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width and Length: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Tincoating:customized

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

Packing:

1、For sheets: plastic or waterproof paper, metallic cover and angles, steel strips,wooden pallet.

2、For Coils: plastic or waterproof paper,plastic protect plate,steel strips.

Both Prime and Secondary Quality Available !!!

- Q: How does tinplate perform in microwave ovens?

- Tinplate should not be used in microwave ovens as it is a metal, and metals can cause sparks or damage to the appliance.

- Q: Can tinplate packaging be used for personal care products?

- Yes, tinplate packaging can be used for personal care products. Tinplate is a durable and lightweight material that provides good protection against moisture, light, and air. It is commonly used for packaging cosmetics, skincare products, and other personal care items. Additionally, tinplate packaging offers a premium and aesthetic appeal, making it suitable for various personal care product ranges.

- Q: What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made of thin sheets of steel coated with a layer of tin, which makes it lighter compared to other metal packaging materials. This lightweight feature allows for easier transportation, storage, and handling, reducing overall costs and increasing efficiency in various industries.

- Q: How is tinplate coated with epoxy resin?

- Tinplate is coated with epoxy resin through a process called electrostatic powder coating. The tinplate is first cleaned and prepared to ensure proper adhesion of the epoxy resin. Then, an electrostatic charge is applied to the tinplate, creating a static field that attracts the epoxy resin particles. The epoxy resin powder is then sprayed onto the tinplate, where it adheres to the surface due to the electrostatic attraction. Finally, the coated tinplate is baked at high temperatures to cure the epoxy resin, creating a durable and protective coating.

- Q: How does tinplate packaging contribute to product protection against light?

- Tinplate packaging contributes to product protection against light by providing a highly effective barrier that prevents light from reaching the product. The tin coating on the steel substrate acts as a reflective layer, reducing the amount of light transmission. This helps to shield the product from harmful UV radiation and other forms of light that can cause degradation, discoloration, or spoilage. Additionally, tinplate packaging can be further enhanced with additional protective coatings or lacquers that provide an additional layer of defense against light exposure, ensuring the product remains intact and protected.

- Q: Can tinplate packaging be used for chemical products?

- Yes, tinplate packaging can be used for chemical products. Tinplate is a durable material that provides excellent protection against corrosion and can withstand the harsh conditions often associated with chemical products. Additionally, it is resistant to moisture, light, and oxygen, which helps maintain the integrity and stability of the chemical contents.

- Q: How is tinplate coated for chemical storage containers?

- Tinplate is typically coated for chemical storage containers using a process called electrolytic tin plating, where a layer of tin is electrochemically deposited onto the surface of the steel substrate. This tin coating helps to protect the container from corrosion and chemical reactions, ensuring safe storage and transportation of chemicals.

- Q: How does tinplate packaging contribute to product reusability?

- Tinplate packaging contributes to product reusability by providing a durable and long-lasting material that can be easily reused for various purposes. Its strong resistance to corrosion and high durability make tinplate packaging suitable for multiple uses, such as storing food, beverages, or other products. Additionally, the ability to seal and reseal tinplate packaging ensures the preservation and freshness of the contents, enabling consumers to reuse the packaging for future storage needs. This reduces waste and promotes sustainability by minimizing the need for single-use packaging materials.

- Q: How is tinplate cut and shaped for different packaging designs?

- Tinplate is cut and shaped for different packaging designs using various techniques such as shearing, blanking, and deep drawing. Shearing involves cutting the tinplate into desired sizes using a sharp blade or scissors. Blanking is a process where the tinplate is cut into a specific shape, usually using a die and a press. Deep drawing involves stretching the tinplate over a die to create a three-dimensional shape, often used for cylindrical or curved packaging designs. These techniques allow for precise and customized shaping of tinplate to meet different packaging requirements.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides through a process called electrolytic tinning. In this process, the tinplate is immersed in an electrolyte solution while an electric current is passed through it. This causes tin ions to be deposited on both sides of the tinplate, resulting in a thin layer of tin coating.

Send your message to us

Tinplate for Metal Tin Containers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords