Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SPECIFICATION

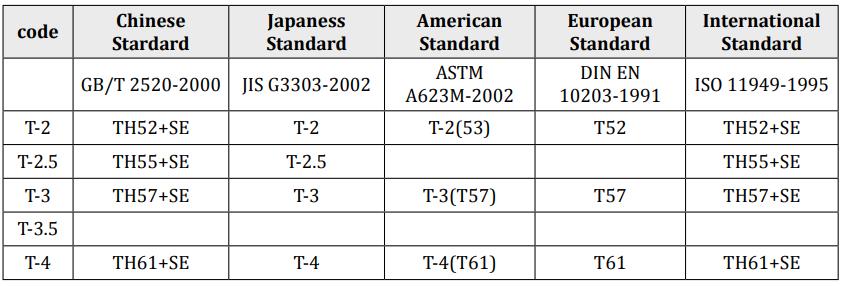

1.Reference standard: GB/T 2520-2000,JIS G3303-2002 and DIN EN 10203-1991

2. Raw material: MR and SPCC

3.Thickness: 0.13 to 0.5mm

4.Width: 600-1050mm

5.Coil diameter: ID 420mm or 508mm

6.Temper: T1~T5,DR8~DR10

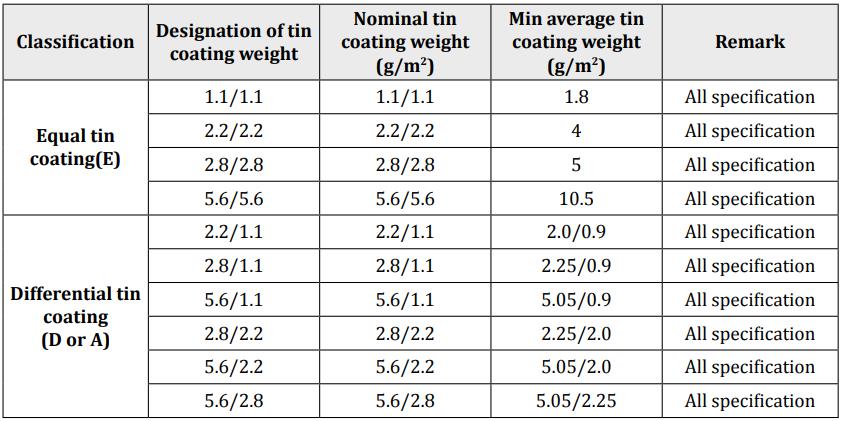

7.Tin coating: 1.1g~11.2g, We can produce according to customer's requests.

8. Applications: paint, chemical and other usage can make battery, electric cable and other industries

9. Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

STANDARD

SURFACE

| Marks | Surface state | Characteristics |

| B | Bright rough | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip featuring certain oriented rubstone figure. |

| RR | St hStone rough | Glazed surface obtained after melting treatment of electrotinned raw material strip featuringg p g certain oriented rubstone figure. |

| S | Silver rough | Glazed surface obtained after melting treatment of electrotinned raw material strip with rough matt surface. |

COATING

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

- Q: Can tinplate be used for renewable energy applications?

- Yes, tinplate can be used for renewable energy applications. It is commonly used for manufacturing solar panels and wind turbines due to its high durability, corrosion resistance, and electrical conductivity properties. Tinplate is also recyclable, making it an environmentally friendly choice for renewable energy projects.

- Q: What are the different coating weights available for tinplate?

- The different coating weights available for tinplate typically range from 1.0 to 11.2 grams per square meter (g/m²), with common options including 2.8, 5.6, and 8.4 g/m².

- Q: How does tinplate affect the overall product visibility?

- Tinplate enhances the overall product visibility by providing a glossy and reflective surface that attracts attention. Its smooth and bright finish allows for excellent printability, making it ideal for branding and product information displays. The reflective properties of tinplate also contribute to the product's visibility on store shelves, catching the eye of potential customers and increasing its overall appeal.

- Q: What are the main innovations in tinplate production and use?

- There have been several key innovations in tinplate production and use. One significant advancement is the development of continuous annealing technology, which allows for more precise control over the tempering process, resulting in tinplates with improved strength and formability. Additionally, the introduction of advanced coating techniques, such as electrolytic deposition and hot dip coating, has enhanced the corrosion resistance of tinplates, making them ideal for packaging food and beverages. Moreover, the use of tin-free steel (TFS) has gained popularity as an alternative to traditional tinplates, offering cost-effectiveness and environmental advantages. Overall, these innovations have revolutionized tinplate production, providing improved quality, versatility, and sustainability in various industries.

- Q: What are the different methods of reusing tinplate packaging?

- There are several methods of reusing tinplate packaging including repurposing them for storage purposes, using them as planters for indoor or outdoor plants, incorporating them into DIY craft projects, or donating them to charitable organizations that can find alternative uses for them.

- Q: How does tinplate contribute to the convenience of pet care products?

- Tinplate contributes to the convenience of pet care products by providing a durable and lightweight packaging option that helps preserve the quality and freshness of the products. It is also easily recyclable, ensuring sustainability while offering a convenient solution for pet owners.

- Q: Can tinplate be used for packaging products with specific storage requirements?

- Yes, tinplate can be used for packaging products with specific storage requirements. Tinplate is known for its excellent protective properties, including resistance to moisture, oxygen, and light, which makes it suitable for preserving the quality and freshness of various products. Additionally, tinplate is highly durable and can withstand temperature variations, making it ideal for packaging products with specific storage needs.

- Q: How is tinplate coated for stationery and office supplies?

- Tinplate for stationery and office supplies is typically coated through a process called electrolytic tin coating. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it, causing tin ions to deposit onto the surface of the metal. This coating provides protection against corrosion and enhances the visual appeal of the tinplate for use in various stationery and office supply applications.

- Q: How does tinplate affect the cost of packaging?

- Tinplate can increase the cost of packaging due to its higher manufacturing and material expenses compared to other packaging materials such as aluminum or plastic. However, it offers various benefits like excellent durability, corrosion resistance, and ability to keep the contents fresh, which can justify the higher cost for certain products.

- Q: How is tinplate coated with organic materials?

- Tinplate can be coated with organic materials through a process called lacquering. This involves applying a thin layer of organic coating, such as lacquer or polymer, onto the tinplate surface. The coating is usually applied using roll-to-roll coating techniques, where the tinplate is passed through rollers while the organic material is spread evenly on the surface. This coating helps protect the tinplate from corrosion, enhances its appearance, and provides a barrier between the metal and the contents of the tinplate package.

Send your message to us

Electrical Tinplate, JIS G3303 Standard For Food Cans & Industrial Cans

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords