Tinplate in SPCC/MR Grade for Coating and Pringting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tinplate

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3303 and GB/T 2520-2008 |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | 2.8/2.8g/m2 , 2.8/5.6g/m2 ,1.1/1.1 g/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

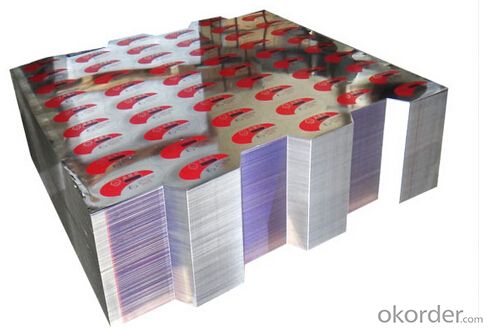

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

Welcome your enquiries and orders.

- Q: What is the shelf life of products packaged in tinplate?

- The shelf life of products packaged in tinplate can vary depending on the specific product and its storage conditions. However, tinplate is known for its excellent protection against moisture, light, and oxygen, which helps to extend the shelf life of packaged goods. Generally, products packaged in tinplate can have a shelf life ranging from several months to years, ensuring product freshness and quality for an extended period.

- Q: How do you solve the water stains on the tinplate?

- Keep in an ample shade of light for about a week, during which time the spray stops.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for the production of packaging materials such as containers, tubes, and caps. It provides excellent barrier properties against moisture, light, and gases, ensuring the integrity and stability of pharmaceutical products. Tinplate is also easy to sterilize, making it suitable for storing drugs and medical devices. Additionally, its durability and tamper-proof properties make it a reliable choice for ensuring product safety and extending shelf life in the pharmaceutical industry.

- Q: What are the common thicknesses of tinplate used for different applications?

- The common thicknesses of tinplate used for different applications vary depending on the specific requirements. However, some common thicknesses include 0.14mm, 0.16mm, 0.18mm, and 0.20mm. These thicknesses are often used in various industries such as packaging, electronics, and automotive.

- Q: How does tinplate packaging contribute to product protection against contamination?

- Tinplate packaging contributes to product protection against contamination by providing a durable and secure barrier between the product and external elements. The tin coating on the steel substrate prevents corrosion and rusting, ensuring the integrity of the packaging. This protects the product from moisture, oxygen, and other contaminants that could compromise its quality or safety. Additionally, tinplate packaging is airtight, preventing the entry of bacteria or microorganisms, further enhancing product protection against contamination.

- Q: How to quickly distinguish tinplate and ordinary substrate iron?

- Tinplate is tin coil, measurement of tin content?. The base plate is a plain hard rolled coil, which is relatively hard without annealing.

- Q: How does tinplate perform in terms of resistance to UV radiation?

- Tinplate generally provides good resistance to UV radiation due to its metallic coating, which acts as a protective barrier against the damaging effects of the sun's rays. However, prolonged exposure to intense UV radiation can still cause some degree of degradation over time.

- Q: Can tinplate be used for agricultural applications?

- Yes, tinplate can be used for agricultural applications. It is commonly used for packaging agricultural products such as canned foods and beverages. Additionally, tinplate can be used for constructing storage containers, agricultural machinery components, and various farming equipment. Its corrosion resistance and durability make it suitable for these applications in the agricultural industry.

- Q: What are the common labeling options for tinplate containers?

- The common labeling options for tinplate containers include adhesive labels, direct printing, heat transfer labels, and lithography.

- Q: Can tinplate be used for packaging agricultural products?

- Yes, tinplate can be used for packaging agricultural products. Tinplate is a popular choice for packaging due to its durability, resistance to corrosion, and ability to protect against light, moisture, and oxygen. It provides a safe and secure packaging solution for agricultural products, ensuring their freshness and extending their shelf life.

Send your message to us

Tinplate in SPCC/MR Grade for Coating and Pringting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords