Electric Tinplate and Tin Free Steel Coil and Sheet for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

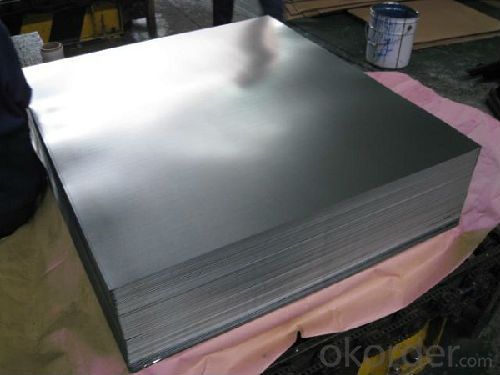

Prime Quality Tinplate Sheets Details

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc. For caps, there are some customers also need TFS, if you have some demand for TFS,also can contact with us.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Minumum Order Quantity: 25 MT Loading Port:China Main Port

Annual Capacity: 400,000MT Payment Terms:TT or LC

Product Specifications:

Prime Quality Tinplate Sheets Usage and Applications

Prime Quality Tinplate Sheets Specifications

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

Applications

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk power cans, tea cans

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends(EOE)

Electrical machinery parts

Bakeware and household kitchen parts

FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

- Q: What's the difference between iron, aluminium, stainless steel, galvanized iron and tin?

- Iron is another kind of material. It is easy to be oxidized (embroidered) when it meets waterGalvanized sheet is made of iron, but zinc is plated on the surface to improve oxidation resistance. The price is cheap

- Q: What are the different methods of recycling tinplate packaging?

- There are several methods of recycling tinplate packaging, including manual separation, magnetic separation, shredding, and melting. Manual separation involves manually sorting and separating tinplate packaging from other materials. Magnetic separation utilizes magnets to separate the tinplate from other metals. Shredding involves cutting tinplate packaging into smaller pieces for easier processing. Finally, melting is a method where the tinplate is melted down and transformed into new metal products.

- Q: How does tinplate perform in terms of product protection?

- Tinplate performs exceptionally well in terms of product protection. Its strong and durable nature ensures excellent resistance against corrosion, moisture, and oxygen, thus safeguarding the contents from external elements. Additionally, its ability to provide an airtight seal helps in preserving the product's freshness, flavor, and quality for an extended period. Overall, tinplate is a reliable and efficient packaging material for ensuring optimal product protection.

- Q: What are the main factors affecting tinplate coil cutting and slitting?

- The main factors affecting tinplate coil cutting and slitting include the thickness and hardness of the tinplate, the quality and sharpness of the cutting tools, the tension and speed of the slitting process, and the expertise and experience of the operators. Other factors may include the cleanliness of the tinplate, the condition and alignment of the slitting machine, and any variations in the tinplate's surface quality.

- Q: Can tinplate be used for marine applications?

- Yes, tinplate can be used for marine applications. Tinplate is known for its excellent corrosion resistance, making it a suitable material for marine environments where exposure to saltwater and moisture is a concern. Additionally, tinplate's strength and durability make it ideal for various marine applications such as packaging, containers, and components for boats and ships.

- Q: How does the tin coating affect the appearance of tinplate?

- The tin coating enhances the appearance of tinplate by giving it a shiny and reflective surface. It adds a lustrous touch to the metal, making it more visually appealing and attractive.

- Q: Does tinplate require any specific handling or storage conditions?

- Yes, tinplate does require specific handling and storage conditions. It should be stored in a dry and well-ventilated area to prevent corrosion. It is also important to handle tinplate with care to avoid any scratches or dents that may compromise its protective coating.

- Q: What are the main challenges in tinplate coating thickness control?

- The main challenges in tinplate coating thickness control involve achieving uniformity and accuracy throughout the entire coating process. This requires overcoming issues such as variations in tinplate surface quality, ensuring consistent application of the coating material, and accurately measuring and monitoring the thickness of the coating. Additionally, maintaining control over the coating parameters and adjusting them appropriately to accommodate different tinplate grades and production conditions is also a challenge. Overall, achieving precise and consistent coating thickness control is crucial for ensuring product quality and meeting customer specifications.

- Q: Both tinplate and stainless steel have corrosion protection

- Stainless steel is added in the iron, Cr, Ni and other corrosion-resistant materials, is fundamentally changed the anti-corrosion properties of materials.

- Q: How does tinplate resist corrosion?

- Tinplate resists corrosion due to the protective barrier created by the tin coating on the surface. This tin layer acts as a barrier, preventing direct contact between the base metal and the corrosive elements in the environment, thus preserving the underlying material from degradation.

Send your message to us

Electric Tinplate and Tin Free Steel Coil and Sheet for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40900 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords