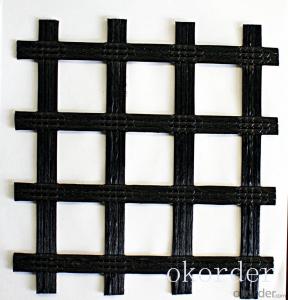

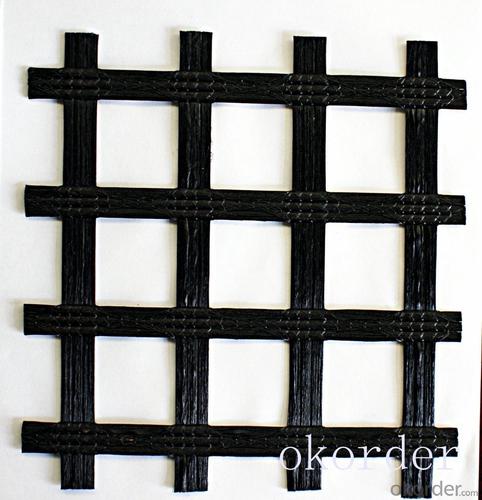

High Quality Geogrids and Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Biaxial

In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

20KN/M--50KN/M

Material:

Plastic

width:

1-6m

Certificate:

CE,ISO

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are commonly used to stabilize soil and prevent erosion, making them an effective solution for protecting shorelines from wave action and water currents. They can be installed in various configurations, such as beneath riprap or as a reinforcement layer for soil, to enhance the stability and longevity of shoreline protection measures.

- Q: How are geogrids manufactured?

- Geogrids are manufactured by extruding or weaving polymer materials such as polypropylene or polyester into a grid-like structure. This process involves melting the polymer, forming it into a grid pattern, and cooling it to create a strong and flexible geogrid.

- Q: Are geogrids effective in preventing soil creep?

- Yes, geogrids are effective in preventing soil creep. Geogrids provide additional reinforcement to the soil, increasing its stability and resistance to movement. They help distribute the forces acting on the soil, reducing the potential for creep and maintaining slope integrity.

- Q: What is the typical cost of a geogrid roll?

- The typical cost of a geogrid roll can vary depending on the size, material, and brand. However, on average, geogrid rolls can range in cost from $100 to $500.

- Q: Details of fiberglass geogrid

- 3, high temperature rutThe asphalt concrete has rheological properties at high temperature, specific performance in summer: asphalt road surface soft and sticky; under the vehicle load, the stress area from depression, vehicle load after the removal of the asphalt surface layer cannot be completely restored to the loading condition before, which produce plastic deformation in the vehicle repeatedly; under the action of rolling plastic deformation accumulation, rutting. We analyze the asphalt pavement structure, because of high temperature asphalt concrete with rheology, while under load, without any constraint mechanism can aggregate movement of the asphalt concrete surface layer, resulting in asphalt surface layer goes on, this is the main reason of the formation of rutting.The fiberglass geogrid is used in the asphalt overlay, which plays the role of skeleton in the asphalt surface layer. The asphalt concrete aggregate throughout the grid, to form a composite mechanical interlocking system, limit the aggregate movement, increase the lateral cover surface layer in asphalt binding, each part of the asphalt layer in each other, to prevent the asphalt surface layer goes on, which plays the role of rutting resistance.

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement and support to the waste materials, preventing slope failure and maintaining the overall integrity of the landfill structure.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on factors such as the quality of the materials used, the specific application, and the environmental conditions. However, geogrids are designed to have a long service life and can often last for several decades under normal conditions.

- Q: Can geogrids be used in temporary construction access mats for environmentally sensitive areas?

- Yes, geogrids can be used in temporary construction access mats for environmentally sensitive areas. Geogrids are a type of geosynthetic material that provides stability and reinforcement to the ground. They are often used in construction access mats to distribute loads and prevent soil erosion. Due to their low environmental impact and ability to protect the underlying soil, geogrids are suitable for use in environmentally sensitive areas where minimizing disturbance is crucial.

- Q: How many square meters of steel plastic geogrid inspection

- The materials of the steel and plastic geogrid need to pass the factory certificate and the inspection report of the manufacturer, and the inspection batch shall be tested by 10 thousand square meters for the base number of 1 times.

- Q: Can geogrids be used in reinforcement of bridge approach embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of bridge approach embankments over soft soils. Geogrids are commonly utilized in civil engineering projects to enhance the stability and load-bearing capacity of soil structures. In the case of bridge approach embankments, geogrids can be installed to improve the overall strength of the soil, reduce settlement, and prevent potential failure or deformation caused by the soft soil conditions.

Send your message to us

High Quality Geogrids and Geocells Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords