MS Hot Rolled Low Carbon Alloy Steel Flat bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

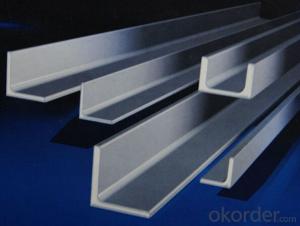

Product Description:

OKorder is offering MS Hot Rolled Low Carbon Alloy Steel Flat bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

MS Hot Rolled Low Carbon Alloy Steel Flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's MS Hot Rolled Low Carbon Alloy Steel Flat bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled and slited

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel flat bars be used for making kitchen utensils?

- No, steel flat bars are not suitable for making kitchen utensils as they are typically made of stainless steel or other food-safe materials that are resistant to corrosion and do not react with food.

- Q: What are the different types of surface defects in stainless steel flat bars?

- There are various types of surface defects that can be found in stainless steel flat bars, which can be categorized into several groups. Some common surface defects in stainless steel flat bars include the following: 1. Pitting: Pitting refers to the formation of small, localized corrosion spots on the surface of stainless steel flat bars. These spots appear as small holes or pits and are usually caused by exposure to aggressive environments such as solutions containing chloride or acidic substances. 2. Scaling: Scaling occurs when oxide layers form on the surface of stainless steel flat bars due to exposure to high temperatures. This results in a flaky or powdery deposit and can happen during processes like heat treatment or welding. 3. Corrosion: Corrosion is the gradual deterioration of the stainless steel surface due to chemical reactions with the environment. It can take various forms, including uniform corrosion, crevice corrosion, or stress corrosion cracking, depending on the specific conditions and environment. 4. Scratches: Scratches are physical marks on the surface of stainless steel flat bars caused by abrasive contact or mechanical damage. They can vary in depth and severity, and if not addressed properly, they can create localized areas of stress concentration and potential sites for further corrosion. 5. Roll marks: Roll marks are imperfections on the surface of stainless steel flat bars that occur during the manufacturing process. They appear as irregular patterns or lines on the surface and are typically caused by the rolling or finishing equipment used in production. 6. Discoloration: Discoloration refers to changes in the appearance or color of the stainless steel flat bar surface. It can be caused by exposure to high temperatures, chemical reactions, or improper cleaning methods. Discoloration can manifest as light or dark patches, streaks, or a rainbow-like effect known as "heat tint" in cases of overheating during welding. It is important to emphasize that surface defects in stainless steel flat bars not only affect their visual appeal but also compromise their corrosion resistance, mechanical properties, and overall performance. Therefore, it is vital to promptly identify, assess, and address any surface defects to ensure the longevity and reliability of stainless steel flat bars.

- Q: What is the tolerance for thickness in steel flat bars?

- The tolerance for thickness in steel flat bars can vary depending on the specific standards and specifications set by the manufacturer or industry. However, in general, the tolerance for thickness in steel flat bars is typically specified within a range of +/- a certain measurement, such as +/- 0.005 inches or +/- 0.13 millimeters. This tolerance ensures that the thickness of the steel flat bars remains within an acceptable range and meets the required dimensional specifications.

- Q: What are the applications of steel flat bars in construction?

- Steel flat bars have a multitude of applications in the construction industry due to their versatility and durability. These bars are widely used in various construction projects for structural support, reinforcement, and framing purposes. One of the key applications of steel flat bars in construction is their use as supports or beams. They can be used to provide additional strength and stability to structures, such as bridges, buildings, and platforms. Steel flat bars are also utilized as lintels above windows and doors, offering structural support and preventing sagging or cracking. Another common application of steel flat bars is in reinforcing concrete structures. These bars are embedded within concrete to provide tensile strength and prevent cracking under heavy loads or vibrations. They are commonly used in the construction of foundations, columns, slabs, and walls. Steel flat bars are also used for framing purposes in construction projects. They can be used as framing members for walls, ceilings, and roofs, providing a strong and rigid framework. Additionally, they can be used as braces to reinforce structures against lateral forces, such as wind or earthquakes. In addition to their structural applications, steel flat bars are also used for decorative purposes in construction. They can be used as architectural accents, handrails, or ornamental fixtures, adding aesthetic appeal to buildings and structures. Overall, the applications of steel flat bars in construction are extensive. Their strength, durability, and versatility make them an essential component in various construction projects, ensuring the stability, safety, and longevity of structures.

- Q: Are steel flat bars heat-treatable?

- Yes, steel flat bars can be heat-treated. Heat treatment is a process used to alter the properties of steel by subjecting it to specific temperature conditions. This process can be used to increase the hardness, strength, and durability of the steel. Heat treatment involves heating the steel to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it at a controlled rate. By carefully controlling the heating and cooling cycles, the structure and properties of the steel can be modified. This allows steel flat bars to be customized to meet specific requirements for different applications.

- Q: What is the carbon content in steel flat bars?

- The carbon content in steel flat bars varies depending on the grade and type of steel being used. Generally, carbon steel flat bars contain a carbon content ranging from 0.15% to 0.60%. However, high carbon steel flat bars can have a carbon content as high as 2.1%. The carbon content in steel flat bars is a crucial factor that determines the strength, hardness, and other mechanical properties of the steel. It is important to consider the intended application and requirements when selecting the appropriate carbon content for steel flat bars.

- Q: What are the different types of surface coatings for steel flat bars?

- Steel flat bars can be coated in various ways to enhance their properties and advantages. Here are some common options: 1. Zinc Galvanization: By applying a zinc layer, the steel flat bar gains protection against rust and corrosion. This makes it suitable for outdoor use or in high humidity areas. 2. Utilizing Powder Coating: Powder coating is a favored choice for steel flat bars due to its durability and attractive finish. It involves spraying dry powder onto the surface and then baking it to create a smooth and hard coating. 3. Opting for Epoxy Coating: Epoxy coatings are renowned for their exceptional adhesion and resistance to chemicals. They are commonly used in industrial settings where the flat bars are exposed to harsh conditions. 4. Applying Paint Coating: Paint coatings allow for customization in terms of color and finish. They provide a protective layer against corrosion and can be easily applied using spray or brush methods. 5. Chrome Plating: Chrome plating entails depositing a thin chromium layer onto the steel flat bar. This coating offers excellent durability and corrosion resistance, making it perfect for applications that require both strength and aesthetics. 6. Employing Black Oxide Coating: Black oxide coating chemically converts the surface of the steel flat bar, resulting in a black finish. It enhances appearance and offers mild corrosion resistance. These examples represent only a fraction of the available surface coatings for steel flat bars. The choice of coating depends on specific requirements such as corrosion resistance, aesthetics, and environmental factors. It is crucial to consider the intended use and conditions in order to select the most suitable coating for steel flat bars.

- Q: Are steel flat bars suitable for earthquake-prone areas?

- Yes, steel flat bars are suitable for earthquake-prone areas. Steel is a strong and durable material that can withstand seismic forces better than other materials. Flat bars provide structural stability and can be used in various applications such as reinforcing structures, bracing walls, or constructing seismic-resistant frames.

- Q: Are steel flat bars suitable for architectural applications?

- Yes, steel flat bars are suitable for architectural applications. They are commonly used in various architectural designs due to their durability, strength, and versatility. Steel flat bars can be easily fabricated and shaped into different forms, making them ideal for creating unique architectural elements. They are often used for constructing frames, supports, and decorative features in buildings, bridges, and other structures. Additionally, steel flat bars have a high resistance to corrosion, which is crucial for maintaining the aesthetic appeal and longevity of architectural designs. Overall, steel flat bars offer a reliable and aesthetically pleasing option for architectural applications.

- Q: What is the maximum length available for steel flat bars?

- The maximum length available for steel flat bars can vary depending on the supplier and manufacturer. However, typically, steel flat bars are available in lengths ranging from 20 feet to 40 feet.

Send your message to us

MS Hot Rolled Low Carbon Alloy Steel Flat bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords