High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality and Stainless Alloyed Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality and Stainless Alloyed Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality and Stainless Alloyed Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications for Stainless Alloyed Flat Bar

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

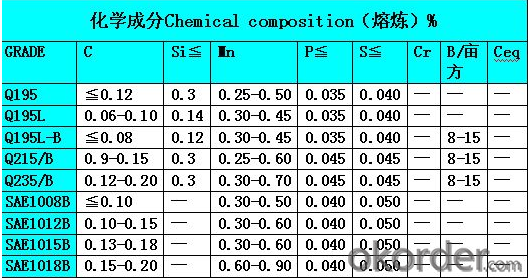

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Are steel flat bars suitable for welding with other metals?

- Yes, steel flat bars are suitable for welding with other metals. Welding steel flat bars with other metals is a common practice in various industries as steel offers good compatibility and excellent weldability with a wide range of metals, including aluminum, stainless steel, and other ferrous and non-ferrous materials. However, it is important to consider the specific properties and compatibility of the metals being welded together, as well as to follow proper welding procedures and techniques to ensure a strong and durable bond.

- Q: What are the different surface finishes for stainless steel flat bars?

- There are several different surface finishes for stainless steel flat bars, including mill finish, brushed finish, mirror finish, and satin finish.

- Q: The grounding electrode 50 angle steel and the ground wire 50, the flat steel lap welding, according to the specification 169 needs the flat steel to be late 90 degrees, bends close to the angle steel side, the overlap width is 4 times (200mm)?

- GB50169-2006 in the 3.4.2 stipulates that the grounding body (line) shall be welded by lap welding, and its lap length shall comply with the following requirements:1. flat steel is 2 times its width (and welded with at least 3 edges);2. round steel is 6 times its diameter;3. round steel and flat steel connection, its length is round steel diameter of 6 times;

- Q: What are the dimensions of a standard steel flat bar?

- The specific requirements and standards set by different industries and countries can lead to variations in the dimensions of a standard steel flat bar. Generally, a standard steel flat bar takes on a rectangular shape, with its width ranging from 1/8 inch to 24 inches and its thickness ranging from 3/16 inch to 1 inch. While the length of a standard steel flat bar is typically 20 feet, it can be customized to different lengths based on the customer's preferences. The intended use, load-bearing capacity, and industry standards are among the factors that determine the specific dimensions of a standard steel flat bar.

- Q: How do steel flat bars perform in terms of thermal expansion?

- Steel flat bars exhibit a comparatively low coefficient of thermal expansion, resulting in reduced expansion and contraction compared to alternative materials in response to temperature fluctuations. Consequently, steel flat bars possess exceptional resistance to warping or distorting caused by thermal expansion. Moreover, their thermal conductivity is relatively high, facilitating efficient heat transfer. These attributes render steel flat bars the preferred option in scenarios where temperature fluctuations are anticipated, including construction, manufacturing, and engineering projects.

- Q: Can steel flat bars be used for manufacturing conveyor systems or belts?

- Yes, steel flat bars can be used for manufacturing conveyor systems or belts. Steel flat bars are often used as support structures or frames in conveyor systems. They provide a sturdy and durable base for the conveyor belts to run on. The flat surface of the steel bars allows for smooth movement of the belts, ensuring efficient and reliable transportation of goods or materials. Additionally, steel is known for its strength and resistance to wear and tear, making it an ideal choice for conveyor systems that require heavy-duty operations. Overall, steel flat bars are a suitable material for manufacturing conveyor systems or belts due to their strength, durability, and smooth surface.

- Q: Are steel flat bars available in different surface roughness options?

- Yes, steel flat bars are available in different surface roughness options.

- Q: Are steel flat bars resistant to impact or vibration?

- Steel flat bars are known for their high strength and durability, which makes them highly resistant to impact and vibration. The composition of steel, along with its structural integrity, enables it to absorb and distribute the energy generated from an impact or vibration. This characteristic makes steel flat bars ideal for various applications where resistance to impact or vibration is crucial, such as in construction, automotive, and industrial settings. Additionally, steel's ability to withstand impacts and vibrations ensures the longevity of structures and components, reducing the risk of damage or failure.

- Q: Are steel flat bars susceptible to warping or bending?

- Yes, steel flat bars are susceptible to warping or bending under certain conditions. Steel is a strong and durable material, but it is not completely immune to deformation. When subjected to excessive stress, heat, or improper handling, steel flat bars can warp or bend. This can occur during the manufacturing process, transportation, or when the bars are exposed to heavy loads or extreme temperature changes. To minimize the risk of warping or bending, it is crucial to handle and store steel flat bars properly, avoid excessive stress or heat, and follow the manufacturer's guidelines for usage and maintenance.

- Q: Can steel flat bars be easily machined?

- Yes, steel flat bars can be easily machined.

Send your message to us

High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords