Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Spring Steel:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Mn | Si | Cr |

0.65~0.75 | 0.40~0.60 | 1.40~1.70 | 0.20~0.40 |

S | P | Ni | |

≤0.030 | ≤0.030 | ≤0.030 |

Mechanical Properties:

-Annealing Condition:

1, Tensile Strength: σb/MPa:≤835

2, Elongation: δ/%:≥8

-Quencher condition:

1, Tensile strength: σb/MPa:785~1175

2, Elongation: -

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Usage/Applications

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

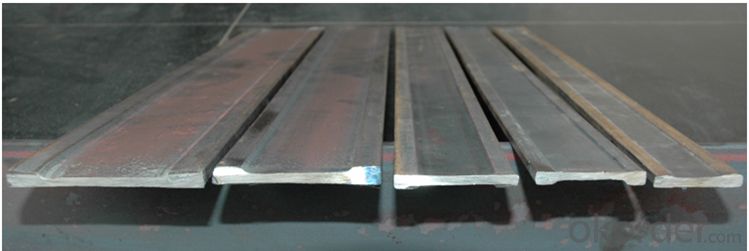

Production Flow of Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel flat bars be powder coated?

- Yes, steel flat bars can be powder coated. Powder coating is a popular method of applying a protective and decorative finish to various metal surfaces, including steel flat bars. Powder coating involves applying a dry powder to the surface of the metal, which is then cured through heat to form a hard and durable coating. This coating provides excellent resistance to corrosion, impact, and abrasion, making it an ideal choice for steel flat bars that may be exposed to harsh environmental conditions or heavy use. Powder coating also offers a wide range of color options, allowing for customization and aesthetic appeal. Overall, powder coating steel flat bars can enhance their durability, appearance, and lifespan.

- Q: How are steel flat bars measured and specified?

- Steel flat bars are typically measured and specified by their width, thickness, and length. The width refers to the measurement across the bar's broadest side, while the thickness indicates the measurement of the bar's narrowest side. The length specifies the overall size of the bar. These measurements are important for accurately determining the dimensions and specifications of steel flat bars, allowing for proper selection and use in various applications.

- Q: How do steel flat bars perform in terms of vibration damping?

- Steel flat bars are known for their excellent vibration damping properties. Due to their high density and stiffness, they effectively absorb and dissipate vibrations, resulting in reduced noise and improved stability. The rigid nature of steel flat bars helps to dampen vibrations, making them a reliable choice for applications requiring vibration control and minimizing resonance.

- Q: What is the difference between hot-rolled and cast steel flat bars?

- The main difference between hot-rolled and cast steel flat bars lies in their manufacturing process. Hot-rolled steel flat bars are produced by heating a steel billet or ingot at a high temperature and then rolling it into the desired shape. This process results in a product with a relatively rough surface and slightly rounded edges. On the other hand, cast steel flat bars are made by melting steel and pouring it into molds to form the desired shape. This casting process results in a smoother surface and sharper edges. Overall, the choice between hot-rolled and cast steel flat bars depends on the specific application and aesthetic preferences.

- Q: What are the different grades of steel used in flat bars?

- Flat bars commonly use several grades of steel, each with unique properties and applications. Some of the most frequently used grades are: 1. Mild Steel (or low carbon steel): This grade is widely utilized in flat bars due to its low carbon content, making it easy to work with and weldable. It finds applications in construction, automotive, and general fabrication. 2. Carbon Steel: With a higher carbon content (usually ranging from 0.30% to 2.0%), carbon steel offers increased strength and hardness compared to mild steel. It is suitable for applications requiring higher load-bearing capabilities, such as machinery parts and structural components. 3. Alloy Steel: This type of steel contains additional elements like manganese, silicon, nickel, chromium, or molybdenum, which enhance mechanical properties such as strength, hardness, and corrosion resistance. Alloy steel flat bars are commonly used in manufacturing tools, gears, and machine parts. 4. Stainless Steel: Stainless steel is corrosion-resistant and contains a minimum of 10.5% chromium. It excels in environments prone to rust, staining, and corrosion, making it ideal for applications in food processing, pharmaceuticals, and marine industries. Stainless steel flat bars come in various grades, with 304 and 316 being the most common. 5. Tool Steel: Designed to exhibit exceptional hardness, toughness, and wear resistance, tool steel is specialized for manufacturing cutting tools, molds, and dies. Tool steel flat bars are available in grades like A2, D2, and O1, each offering specific properties for different applications. These examples represent only a few of the many specialized grades available for flat bars, including heat-resistant steel, wear-resistant steel, and high-strength steel. The choice of grade depends on specific application requirements, such as strength, corrosion resistance, hardness, and other properties.

- Q: Building poles, outdoor flat steel, the deeper the buried depth, the better?

- Building poles, outdoor flat steel, buried depth is not as deep as possible. According to the standard requirements, the level of the embedded depth is not less than 0.6 meters.

- Q: Can steel flat bars be used for making brackets or supports for electrical substations?

- Certainly! Brackets or supports for electrical substations can indeed be crafted using steel flat bars. Steel, renowned for its strength and durability, possesses the essential structural support needed for electrical equipment and components. Moreover, steel exhibits commendable resistance to corrosion, a crucial attribute when considering outdoor substations' placement. By conveniently fabricating and tailoring steel flat bars, they become an ideal choice for manufacturing brackets or supports that effectively secure and safeguard electrical equipment in position, meeting precise design specifications.

- Q: Are steel flat bars commonly used in construction?

- Steel flat bars are frequently employed in construction due to their versatility and ability to serve a wide array of purposes, including the construction of frames, supports, brackets, and reinforcement in concrete structures. Offering strength, durability, and stability, steel flat bars are highly suitable for construction endeavors. Architects and engineers favor them because they can be easily welded, cut, and shaped to meet specific design specifications. Furthermore, the cost-effectiveness and ready availability of steel flat bars contribute to their widespread utilization in the construction sector.

- Q: Can steel flat bars be used for making shelving or storage units?

- Steel flat bars are a versatile choice for constructing shelving or storage units due to their durability and strength. They are capable of holding heavy items and enduring frequent use. Moreover, steel flat bars offer the flexibility to create customized storage solutions through welding or bolting, ensuring a perfect fit for specific needs and spaces. In addition to their practicality, the sleek and modern appearance of steel flat bars adds an aesthetic appeal to shelving or storage units, making them suitable for both residential and commercial settings. Ultimately, steel flat bars serve as a dependable and robust foundation for building long-lasting and functional shelving or storage units.

- Q: Can steel flat bars be used for making brackets or supports for medical equipment?

- Yes, steel flat bars can be used for making brackets or supports for medical equipment. Steel is a strong and durable material that can provide the necessary stability and support required for medical equipment. It has excellent load-bearing capabilities and can withstand high amounts of pressure or weight. Additionally, steel is resistant to corrosion, which is crucial for medical equipment that may come into contact with moisture or other potentially damaging substances. Overall, steel flat bars are a suitable choice for creating brackets or supports for medical equipment due to their strength, durability, and resistance to corrosion.

Send your message to us

Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords