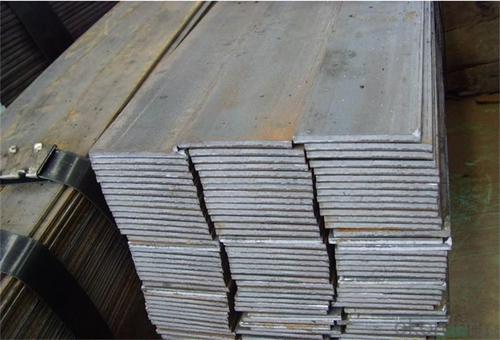

Spring Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Steel Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Usage/Applications of Steel Flat Bar

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Packaging & Delivery of Mild Steel Flat Bar

Packaging Details: The Mild Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

Production Flow of Steel Flat Bar

The Mild steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How does special steel perform in extreme environments?

- Special steel is specifically designed to perform exceptionally well in extreme environments. It has excellent resistance to corrosion, high temperatures, and mechanical stress, making it highly reliable and durable. Special steel also maintains its strength and integrity even in challenging conditions, ensuring optimal performance and longevity in extreme environments.

- Q: Can special steel be used in the energy sector?

- Indeed, the energy sector can utilize special steel. This term encompasses a range of high-performance alloys that are specifically crafted for applications necessitating exceptional strength, durability, and resistance to corrosion and extreme temperatures. These qualities render special steel an optimal choice for numerous components employed in the energy sector. Within the oil and gas industry, special steel is frequently employed in the construction of pipelines, drilling equipment, and offshore platforms. Its robustness and resistance to corrosion guarantee the integrity and reliability of these vital structures, even in challenging environments. Special steel is also extensively employed in power generation plants. For instance, in thermal power plants that generate steam for electricity production, special steel is employed in the production of boiler tubes and pressure vessels. The extraordinary heat resistance and structural integrity of special steel ensure the secure and efficient operation of these components, even under high temperatures and pressure. Moreover, special steel finds applications in the renewable energy sectors, such as wind and solar power. In the case of wind turbines, special steel is utilized in the manufacturing of rotor shafts, gears, and bearings, all of which undergo substantial mechanical loads. Similarly, in concentrated solar power plants, special steel is employed for the construction of heat exchangers, receivers, and storage systems. Overall, the presence of special steel in the energy sector plays a pivotal role in enhancing the performance, safety, and longevity of various components and structures. Its exceptional properties make it an indispensable material, supporting the infrastructure and operations of the energy industry.

- Q: How does special steel perform in abrasive wear conditions?

- Special steel performs well in abrasive wear conditions due to its high hardness and toughness. It has excellent resistance to abrasion, which allows it to withstand the rubbing, scraping, and grinding that occurs in abrasive environments. The unique composition and heat treatment of special steel enhance its ability to resist wear and maintain its structural integrity, making it an ideal choice for applications where abrasive wear is a concern.

- Q: What are the applications of special steel in the manufacturing sector?

- Special steel has numerous applications in the manufacturing sector due to its exceptional properties. It is commonly used in industries such as automotive, aerospace, construction, and machinery manufacturing. Special steel is utilized for manufacturing high-performance components, tools, and machinery parts that require superior strength, durability, and resistance to wear and corrosion. Its applications range from manufacturing gears, shafts, bearings, and springs to constructing bridges, buildings, and pipelines. Additionally, special steel finds use in the production of cutting tools, molds, and dies, further enhancing the efficiency and precision of manufacturing processes.

- Q: How is special steel used in the oil and gas industry?

- Special steel is used in the oil and gas industry for various applications such as manufacturing drill pipes, casings, and pipelines, as well as components for offshore platforms and equipment. It is highly resistant to corrosion, high temperatures, and extreme pressures, making it suitable for harsh environments and ensuring the integrity and safety of infrastructure in the industry.

- Q: What are the main characteristics of corrosion-resistant steel?

- The main characteristics of corrosion-resistant steel include a high level of resistance to rust, corrosion, and staining. It is typically made with alloying elements such as chrome, nickel, and molybdenum, which enhance its ability to withstand harsh environments and corrosive substances. This type of steel is also known for its durability, strength, and longevity, making it suitable for a wide range of applications in industries such as construction, automotive, and marine.

- Q: How does special steel contribute to the manufacturing of springs?

- Special steel plays a crucial role in the manufacturing of springs due to its unique properties and characteristics. Springs are mechanical components that store and release mechanical energy, and special steel provides the necessary strength, durability, and resilience for these applications. One of the key contributions of special steel to spring manufacturing is its high tensile strength. Special steel alloys are designed to have a higher strength-to-weight ratio compared to regular steels, allowing springs to withstand heavy loads and high stresses without deforming or breaking. This property ensures the longevity and reliability of springs, even in demanding applications such as automotive suspensions or industrial machinery. Furthermore, special steel exhibits excellent elasticity and resilience. Springs need to retain their shape and performance over repeated cycles of compression and extension. Special steel alloys are formulated to have a high elastic limit, meaning they can be deformed significantly and still return to their original shape without permanent deformation. This property allows springs to absorb and release energy reliably, providing the desired mechanical functionality in various applications. Another important contribution of special steel to spring manufacturing is its resistance to fatigue and corrosion. Springs are often subjected to cyclic loading, which can lead to fatigue failure over time. Special steel alloys are designed to have enhanced fatigue resistance, allowing springs to endure millions of cycles without failure. Additionally, special steel can be further treated or coated to enhance its corrosion resistance, which is crucial for springs exposed to harsh environments or chemicals. In conclusion, special steel significantly contributes to the manufacturing of springs by providing high tensile strength, excellent elasticity and resilience, fatigue resistance, and corrosion resistance. These properties ensure the durability, performance, and longevity of springs, making them essential components in various industries such as automotive, aerospace, and manufacturing.

- Q: How does special steel contribute to the manufacturing of consumer goods?

- Special steel plays a crucial role in the manufacturing of consumer goods by offering superior strength, durability, and corrosion resistance. It enables the production of high-quality products such as automobiles, appliances, cutlery, and tools, ensuring their longevity and performance. The use of special steel enhances the overall quality and reliability of consumer goods, leading to increased customer satisfaction and product longevity.

- Q: How is special steel used in the production of injection molds?

- Special steel is commonly used in the production of injection molds due to its high strength, durability, and resistance to wear and corrosion. These properties make it ideal for withstanding the high temperatures, pressures, and repetitive stresses involved in the injection molding process. Additionally, special steel's excellent heat conduction enables efficient cooling, resulting in faster production cycles and improved part quality. Overall, the use of special steel in injection molds ensures the production of high-quality, precise, and consistent plastic parts.

- Q: What are the specific requirements for special steel used in the railway track industry?

- The specific requirements for special steel used in the railway track industry are designed to ensure the safety, durability, and efficiency of the tracks. Firstly, the steel used for railway tracks must have a high tensile strength to withstand the heavy loads and constant stress applied by trains. This strength allows the tracks to maintain their shape and prevent deformation, ensuring smooth and stable movement of the trains. Secondly, the special steel used in railway tracks must have excellent wear resistance. As trains constantly traverse the tracks, there is significant friction and wear between the train wheels and the tracks. Therefore, the steel needs to be able to withstand this wear and tear, minimizing the need for frequent maintenance and replacement. Thirdly, the steel used in railway tracks must have good fatigue resistance. Trains exert repetitive loads on the tracks, which can lead to fatigue failure if the steel is not able to withstand this cyclic loading. Fatigue resistance ensures that the tracks remain intact and safe for prolonged periods, reducing the risk of accidents. Furthermore, the steel must have high corrosion resistance to withstand exposure to various environmental and weather conditions. Railway tracks are exposed to moisture, temperature variations, and other corrosive elements, making it crucial for the steel to have the ability to resist rust and corrosion. In addition to these mechanical and physical properties, the steel used in the railway track industry must also meet specific dimensional and geometric requirements. This includes precise dimensions, straightness, and alignment to ensure proper installation and alignment of the tracks, allowing for smooth and safe train operations. Overall, the specific requirements for special steel used in the railway track industry revolve around strength, wear resistance, fatigue resistance, corrosion resistance, and dimensional accuracy. Meeting these requirements is essential to ensure the safety, longevity, and efficiency of railway tracks, facilitating smooth and reliable train transportation.

Send your message to us

Spring Steel Flat Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords