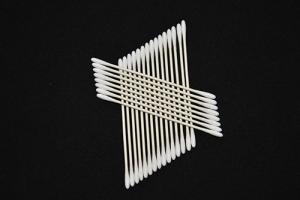

High Quality Stainless Steel 410 0.13mm for scourer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scourer wire is used for making mesh scourers, spiral scourers and relative products.

1.The diameter of wire: 0.12mm, 0.13mm, 0.2mm, 0.7mm and so on.

2.The materia of scourer wire: AISI 430, AISI 410, hot gavalnized wire, electrical galvanized wire and so on.

3.Weight: 15kg/spool

4. Carton Packing: 2spools in one carton

5. Payment: 30%T/T, the balance against B/L copy.

6. MIN order :5mts

SPECIFICATIONS

Cleaning ball of their materials, including stainless steel wire, high-zinc wire, low-zinc wire, copper wire. Change Roberts and so on. Selection of high quality raw materials made of advanced high-zinc wire, low-zinc wire, product specification: 0.70mm - 0.20mm high-zinc plate wire is installed, 0.20mm - 0.13mm high zinc thread shaft-mounted, 0.70mm - 0.20mm wire is a low-zinc plate loaded, 0.20mm - 0.13mm wire is a spool loaded with low zinc and high zinc wire 0.70mm especially in the quality good, the amount of zinc up to 50 grams, pulled out of silk special Liang Bai. plating (galvanizing) Zinc wire is a low-carbon steel core wire, by Roberts, electroplating (hot dip) process processed into zinc metal compound material. Is mainly used in manufacture of metal wire, nail-making, highway guardrail and wire bundles and other construction.

Our company has specialized in this item for 10 years.

We can offer various items scourers with high quality and low price.

And have enjoyed a high popularity with customers worldwide.

Hoping to have a good cooperation with you in near future.

- Q: The equipment of our unit needs to be cleaned regularly, oil pollution is very much, every time manual washing efficiency is too low, what method can be solved quickly?

- First, the source and composition of the oil pollution should be made clear. In particular, it is clear that it is possible to take medicine against the disease. The oil on general equipment is divided into two categories: lipids and oils. The best way to deal with lipids is by physically removing and chemical decomposition. In the case of oils, the main thing is chemical decomposition. Because you do not know the type and structure of your device, you can only suggest the following: 1, before manual cleaning, the specific chemical decomposition should be arranged so that the cleaning can be twice as effective. According to the source of the oil pollution, do the precautionary setting. For example, it is easier to paste the protective coating on the spot where the oil pollution is frequently occurring. Use special tools and equipment to clean up the oil. Personal sense, the process of decomposition is important. For your reference.

- Q: Is it better to clean insulators with ultrasonic cleaning equipment or to clean them?

- The question is not clear, do you want to know its function or what? Ultrasonic cleaning machine, I ever did for cleaning artifacts such as metal and glass surface oil pollution, dust effect is very good, now the application is quite widespread, especially in auto parts, circuit boards, and solar wafers. If you buy a large scale of 40-600,000, small four, five thousand to 10,000, the individual factory in huaibei is not much, I can't imagine what kind of work you do.

- Q: What should I consider? To solve the

- Cleaning equipment at present, a lot of international medical devices by using ion exchange, reverse osmosis and ion exchange group legal and reverse osmosis and EDI combination preparation of medical apparatus and instruments clean water, the water treatment equipment manufacturers aimed at the development of medical cleaning equipment market space, are put into research and development industry. According to the process of the preparation of ultra-pure water, there must be an advantage in the development of devices.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- The main difference: Service life: no less than 5, 000 hours in industry and not more than 2, 000 hours in general. Second, can carry on a continuous cleaning operation and the general cleaning machine can not do the continuous cleaning, can only be used intermittently. Third, the ability to adapt to the environment: the industry can adapt to the bad indoor environment or the outdoor working environment and the general cleaning machine is less adaptable. The industrial type is 1.5 to 2 times larger than the commercial machine, and the overall weight of the equipment is large. The general cleaning machine is beautiful in appearance, and it is very bad for the impact and collision ability.

- Q: How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q: Introduction of geothermal cleaning equipment

- Search: geothermal cleaning equipment is high pressure cleaner, steam cleaner, new urban stain removal truck, pipeline dredge machine, intelligent automatic pulse geothermal cleaning machine, washing machine, air preheater, condenser cleaning machine, pipe cleaning machine, high pressure water jet cleaning machine, boiler cleaning machine, central air conditioning cleaning machine, large municipal pipeline dredge vehicle, and hydraulic test pump

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- This time is dirty time, oneself according to the production requirements for 3 days, 3 days after completing equipment use clean, if qualified, cleaning validation then SOP can regulation equipment should be used in within 3 days from the end of the cleaning.

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- The tank cleaning industry at present, the general take artificial cleaning, mechanical equipment cleaning tank is just rise recently, really can do mechanical cleaning also does not have a few, and some manufacturers are generally abroad, prices more expensive each device also need to around 10 million, as currently on the market what the robot cleaning tank while the price is cheaper, but the technology is relatively insecure, we cleaning company is this year just at the beginning of the year on a mechanical cleaning equipment, the effect is good, the key is cheap compact result, oil recovery rate can reach 90%, in the process of cleaning is content value.

- Q: How do you clean the household central air conditioner

- It is mainly the filtration grid that is cleaning outlet, if can ask professional person to clean the wind channel is better

- Q: What are the appliances cleaning equipment

- A steam engine, a steam engine Air conditioning cleaning machine Water heater cleaning machine Water cooler Multi-function sterilizer Geothermal cleaning machine

Send your message to us

High Quality Stainless Steel 410 0.13mm for scourer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords