Stainless Steel Plate 409L with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

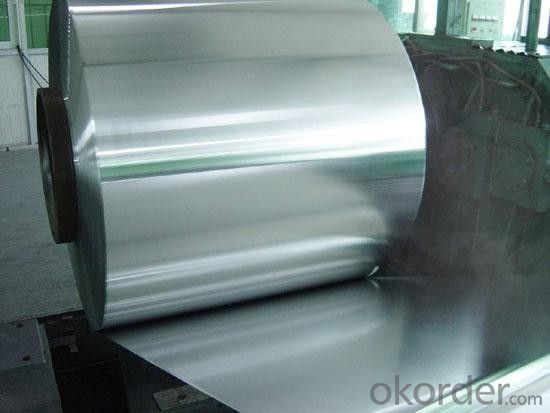

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How are stainless steel sheets installed?

- Different methods are used to install stainless steel sheets depending on the specific application and requirements. Here are several common installation methods for stainless steel sheets: 1. Adhesive: A popular and straightforward method involves using a specialized adhesive to bond the stainless steel sheet to the desired surface. The adhesive is applied to the back of the sheet, which is then firmly pressed onto the surface. This method is suitable for flat or slightly curved surfaces and results in a seamless and clean installation. 2. Mechanical fasteners: When additional strength and stability are necessary, stainless steel sheets can be installed using mechanical fasteners like screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it. This method is often used for installations that require resistance to external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be employed to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Certain stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method offers quick and convenient installation as the sheets can be easily repositioned or removed if necessary. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to thoroughly clean the surface and remove any dirt, dust, or grease. This preparation will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines specific to the stainless steel sheet being installed is essential for achieving the best results.

- Q: What are the different types of stainless steel sheet thicknesses available?

- There is a wide variety of stainless steel sheet thicknesses to choose from, each serving different purposes and applications. The most commonly used thicknesses range from 0.4mm to 3.0mm, with increments of 0.4mm. These sheets are typically utilized in general applications such as construction, automotive parts, and household appliances. For more specialized applications, one can find thinner stainless steel sheets with thicknesses ranging from 0.1mm to 0.3mm. These thinner sheets are commonly employed in industries like electronics, telecommunications, and medical equipment manufacturing, where precise and delicate components are necessary. On the other hand, thicker stainless steel sheets, starting from 3.0mm and going up to 20mm or more, are reserved for heavy-duty applications like industrial machinery, shipbuilding, and construction projects that require exceptional structural integrity and durability. It's important to keep in mind that the available stainless steel sheet thicknesses may vary depending on the manufacturer and the intended use. Moreover, custom thicknesses can be manufactured to meet the specific requirements of a project.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: Are stainless steel sheets resistant to hydrochloric acid?

- Stainless steel sheets are typically able to resist hydrochloric acid. The corrosion resistance of stainless steel is well-known, as it has been proven to endure various types of acids, including hydrochloric acid. Nevertheless, the level of resistance may differ depending on the stainless steel's grade and composition. Extended exposure to concentrated hydrochloric acid or elevated temperatures may result in corrosion or harm. Hence, it is advisable to seek guidance from a stainless steel expert or consult the corrosion resistance chart for the specific stainless steel grade to ascertain the appropriateness of stainless steel sheets for a specific application involving hydrochloric acid.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in swimming pools. It is resistant to rust, stains, and chemicals commonly found in pool water, making it a reliable choice for long-term use. Stainless steel sheets are often used for pool walls, floors, and other structural components because they can withstand the harsh conditions associated with pool environments. Additionally, stainless steel has a sleek and modern appearance, adding to the overall aesthetics of the pool.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved. Etching and engraving are common methods used to create designs, patterns, and text on stainless steel surfaces. These techniques involve removing a thin layer of the metal to create the desired design. Etching can be done using chemicals or by using a laser, while engraving is typically done using a mechanical tool or laser. The etching or engraving process can create intricate and detailed designs on the stainless steel sheets, making them suitable for a wide range of applications such as signage, decorative panels, nameplates, and more.

- Q: Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not as effective as other materials specifically designed for soundproofing, it still has some soundproofing properties. Stainless steel sheets have a high density which helps in reducing sound transmission. Additionally, they have good reflective properties, meaning they can reflect sound waves and prevent them from passing through. However, it is important to note that for effective sound insulation, it is recommended to use materials specifically designed for this purpose, such as acoustic panels or soundproof curtains, as they offer better sound absorption capabilities.

- Q: What is the impact strength of stainless steel sheets?

- The impact strength of stainless steel sheets is relatively high compared to other materials, making them resistant to cracks and fractures when subjected to sudden forces or impacts.

- Q: Do stainless steel sheets require any special handling during installation?

- Yes, stainless steel sheets do require special handling during installation. Here are a few important considerations: 1. Avoid Contamination: Stainless steel is prone to contamination from various sources, such as carbon steel, dirt, or grease. It is crucial to ensure that the installation area is clean and free from any potential contaminants. Tools used during installation should also be clean and free from other metals. 2. Protection from Scratches: Stainless steel sheets are susceptible to scratching during installation. It is important to handle them with care and use protective coverings or wraps to prevent any scratches or damage. Additionally, using non-abrasive tools and avoiding dragging or sliding the sheets across surfaces can help maintain their integrity. 3. Proper Fixing Techniques: Stainless steel sheets are typically secured using mechanical fasteners or adhesives. It is essential to follow the manufacturer's recommendations or industry best practices for the specific installation method. This includes using the correct type and size of fasteners and ensuring they are properly tightened without over-torquing, which can cause damage. 4. Expansion and Contraction: Stainless steel sheets can expand or contract with changes in temperature. During installation, it is necessary to allow for this movement by providing adequate clearance or using expansion joints where required. Failing to account for thermal expansion can lead to buckling, warping, or stress on the sheets. 5. Avoiding Galvanic Corrosion: Stainless steel sheets should not come into direct contact with dissimilar metals, especially those with higher galvanic potential, as it can cause galvanic corrosion. Using compatible materials and insulating stainless steel sheets from direct contact with other metals can help prevent this type of corrosion. By following these special handling guidelines, stainless steel sheets can be installed correctly, maintaining their aesthetic appeal and durability over time.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, there are several preventive measures that can be taken: 1. It is crucial to handle stainless steel sheets properly, avoiding any scratching or rubbing of the surface that could lead to fretting corrosion. Gloves should be worn and contact with other metals or rough surfaces should be avoided. 2. Regular cleaning of the stainless steel sheets using mild detergents or specialized stainless steel cleaners is recommended. This helps to remove contaminants that can initiate corrosion and prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion, especially in applications with repeated movement or vibration. 4. Whenever possible, it is advised to isolate stainless steel sheets from direct contact with other metals. This can be achieved by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular inspection of the stainless steel sheets is important to detect any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. It is recommended to consult with a professional to determine the most suitable coating for the specific application. 7. Proper storage of stainless steel sheets is essential. When not in use, they should be stored in a clean, dry environment to minimize exposure to moisture or corrosive substances. The storage area should be well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, the risk of fretting corrosion on stainless steel sheets can be significantly reduced, ultimately prolonging their lifespan.

Send your message to us

Stainless Steel Plate 409L with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords