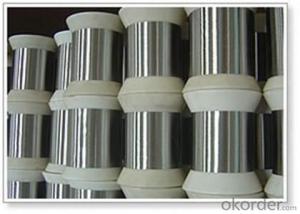

SS 410 Scourer wire 0.13mm & stainless steel scourer machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Staianless Steel Wire Or Hot dipped Galvanized wire is available.

1)Application: | Fencing wire (Panel wire),Bucket handle wire,Baling wire,Vineyard wire,Fine mesh wire,PVC coated wire, Spring Wire, Roping Wire, ACSR wire Etc and other application |

2) Material: Surface: electro,Hot dipped, PVC Coated | low carbon steel wire, middle carbon steel wire high carbon steel wire, Stainless Steel Wire 410, 430

|

3)Diameter: | 0.16mm-8.00mm |

4)Tensile strength: | 300-2100MPA |

5) Packing: | 0.5kg-800kg, in small coils, big coils and on spool or drums |

6)Standard: | AS PER YOUR REQUSRTER |

7) All can be produced according to customers’ actual requirement. | |

Technical Information: Processing with low carbon steel wire, through drawing and electric galvanizing ,Standard wire gauge from 8# to 16#.

Applications: Communication devices, medical treatment equipment, weaving of wire mesh, making of brushes, steel rope, filter wire mesh, high pressure pipes, construction, arts and crafts, etc.

Material:

super carbon steel

Processing by drawing, hot-dip zinc-plating ,Standard wire gauge from 8# to 24#

Thick zinc-coating layer

Super in corrosion resistance

Firm coating layer

Custom size available ruction.

- Q: What are the benefits of sanitation

- It's good for the equipment and it's comfortable to watch

- Q: Is it better to clean insulators with ultrasonic cleaning equipment or to clean them?

- The question is not clear, do you want to know its function or what? Ultrasonic cleaning machine, I ever did for cleaning artifacts such as metal and glass surface oil pollution, dust effect is very good, now the application is quite widespread, especially in auto parts, circuit boards, and solar wafers. If you buy a large scale of 40-600,000, small four, five thousand to 10,000, the individual factory in huaibei is not much, I can't imagine what kind of work you do.

- Q: Procter &gamble has some common cleaning equipment in the cleaning of the property

- Electric escalator cleaning machine: the clean and dry cleaning and drying of electric escalators are the best choice, easy to operate, multi-function and clean environment. Special design for escalators with different softness to choose from. Vacuuming, "water" as a filtration system, and equipped with a drain. The brush cover is equipped with special cleaner distributing device, easy to operate, easy to clean or change. Solve the problem of the traditional cleaning escalator.

- Q: What is the cleaning equipment?

- Cleaning equipment categories: push car wash machine to wash to wash his hands to machine driving type cleaning machine automatic car washing machine to clean the floor sweeping machine hand push sweeping machine driving type of the machine Automatic sweeping machine industrial vacuum cleaners, etc.

- Q: Characteristics of cleaning equipment of cleaning equipment

- High pressure cleaner using high pressure water jet cleaning technology, which is in the 1960 s the rise of a technology, widely used in the removal of incrustation scale proliferation, oil and other hydrocarbons residue coking, also can remove all kinds of coating stab stick coagulation soil lipid layer of gypsum, pigment, rubber, plastic, etc

- Q: The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q: What cleaning equipment does the factory clean equipment need?

- Lucky for you! I am also a factory and recently bought a lot of factory cleaning equipment. As far as I know, the cleaning equipment of the factory can be divided into cleaning equipment and cleaning equipment. Our factory in shenzhen buji there was the last time a company called jie I now, is dedicated to sell industrial cleaning equipment company to buy the machine, the staff attitude is very good, also very professional! Ask for advice if you need it

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- Last year took part in the issue of dedicated to verify training on cleaning validation Wang Yanzhong teacher to explain this one is so blue font: if you don't clean immediately after the equipment use, such as when a couple of days to clean again, need to confirm according to have validated cleaning method can clean the equipment when cleaning equipment, there may be some material put a few days after has been hard on the equipment surface, not as easy as immediately when cleaning clean. So the time that the device is used up to cleaning is going to be validated.

- Q: How do you clean the household central air conditioner

- Household central air conditioning main cleaning filter and the house of the dirt on the condenser fin, under normal circumstances can filter down to water boiling, outdoor hoses washed clean. As for the internal cleaning of the refrigeration system, it is usually not necessary to clean the system as long as it is cleaned.

- Q: It is best to wash mechanical equipment using that cleaner

- It is recommended that the blue flying machine will be used for cleaning the surface of the equipment, cleaning the surface of the equipment and not damaging the paint on the surface of the equipment.

Send your message to us

SS 410 Scourer wire 0.13mm & stainless steel scourer machinery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords