Zinc Galvanized Drywall Metal Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

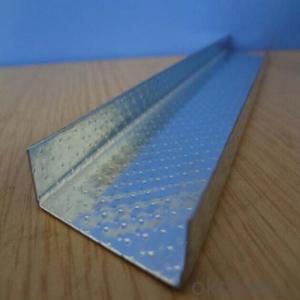

Name | Zinc galvanized drywall metal stud and track |

Standard | AISI,ASTM,BS,DIN,GB,JIS |

Type | Metal stud and track |

Place of Origin | Hebei, China (Mainland) |

Technique | Cold rolled, hot rolled |

Surface Treatment | Hot dipped galvanized, with dots, no dots |

Application | Structural use, roofing, industry |

Length | Can be customized |

Thickness | 0.1-1.0mm |

Zinc coating | 40--180 g/m2 |

MOQ | 1000pcs |

Delivery time | 15-20 days after receive your deposit |

Specification

Item | Specification (mm) | |

Width | Height | |

V channel | 30/38 | |

Main channel | 38 | 10/12/14 |

Main channel | 50 | 12/15 |

Cross channel | 50 | 15/17/19 |

Cross channel | 60 | 27 |

Cross channel | 38 | 27 |

Furring channel | 35 | 22 |

U angle | 29 | 24/29 |

L angle | 22-35 | |

Track /Horizontal Channel | QU/UW | 50/75/100x35/40/50x0.45mm |

Stud/Vertical Channel | QC/CW | 50/75/100x35/40/50x0.45mm |

Omega Furring Channel | Ω | 35x22x12/13mm |

Advantages

1.Professional manufacturer for more than 15 year, strict quality control systerm make sure high quality product.

2.Advanced production equipment make sure production capacity reach 400,000 tons per year and exactly size.

3.Prime quality and competitive price make sure our metal stud and track warm sales in Middle East, Africa, Australia, America and other oversea markets.

4.Strict quality control systerm and scientific management systerm make sure prime quality.

5.Professional trading team make sure best services and timely reply for your inquiry.

6.Trade assurance mount $6000 granted by alibaba.com make sure safe payment.

Packing details:

1. Metal stud and track wrapped by waterproof paper

2.Inner and outer edge tied by steel strip or clear tape

3.The whole stud and track bundle supported by wood pallet

4.Can make as customer's requirement.

Shipping details:

1.Delivery time:15-20 days after receiving the deposit

2.The stud and track bundles fixed well by the steel ropes in the container.

3.We can arrange shipping details for you with the shipping company.

Our services

Remarks | 1. If you email to us, we will get back to you within 12 hours, normally a lot sooner |

2. Make sure the size and thickness, you will get a more precise price | |

3. We provide many lenth for your choise | |

4. Estimated delivery may be affected by holidays, such as spring festival,national day | |

5. Free sample is acceptable, just you should pay the delivery fees | |

6. Free document: commercial invoice, packing list, and certification of original | |

7. The price of the models are subject to our final confirmation | |

8. Payment: T/T and L/C | |

9. FOB port: Tianjin China |

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- The interior walls can be made of light steel keel partitions, but the bathroom walls should be made of brick walls. The bathroom is generally water, wall with gypsum board, then the gypsum board will be bad water. So apply brick walls, and then paste the tiles on top.

- Q: I was not a tool in the category, or else I got myself!

- General package material single-sided more than one hundred double-sided more than two hundred square meters, there are special sound insulation wall board, the effect is very good, but the area is not big people do not necessarily do

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q: Light steel keel wall in the end is how much money to know

- The partition depends on whether you are single or double-sided single-sided 30 a square double-sided 50 a square called 70 are cut your gypsum board has 13 to 23 blocks have you do partition And not good gypsum board as long as 14 to 15 pieces of gypsum board on it

- Q: Can my light steel keel ceiling withstand the weight?

- According to your argument is no problem. Please feel free to use it

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- The walls of the bathroom must be waterproof and moistureproof, or it will be deformed and affect life. And the bathroom wall to do the waterproof treatment, or the toilet to the area of water and more will then penetrate the other side of the wall.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- In order to be able to make decoration more perfect, it is recommended that you choose the decoration manufacturers, to be careful, we must choose the same brand of all products. The

- Q: Decorative light steel keel paper gypsum board wall height of 4.1 meters span 6.5 meters need not add structural column, beam

- If there is no stiffness requirement for the wall, there is no need to increase. If there is such a request, it is necessary to increase the minimum of three steel square pillars and two steel square cross.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- If the middle of the empty iron angle, it is estimated that the master will be in the corner iron welding rods down to install! Some of the master will use wire hanging, but many people do not use the iron wire rod. Then install baking paint or paint keel, Put the mineral wool board up just fine!

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board wall, refers to the surface with gypsum board to do the closed wall, it is also a "light partition" of a. Lightweight partition, which includes gypsum board partition, cement board partition, light block brick wall and so on.

Send your message to us

Zinc Galvanized Drywall Metal Stud and Track

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords