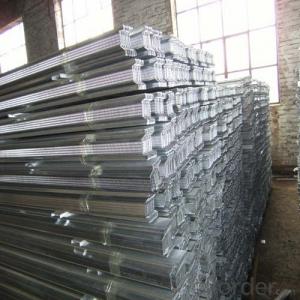

Drywall Metal Profile of Stud Zinc Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- The general keel material costs 34 or so manual 15 that you look at the offer

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Generally just a few fixed points on it, because the gypsum board sealed, the formation of a whole, The weight is under pressure, it can not move.

- Q: Light steel keel wall waterproof

- 1. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) Used for bonding with the substrate, to achieve 100% continuous sticky. 2. Use 1032 to enhance the polyester cloth Used to enhance the coating of tensile, tear resistance and fatigue resistance. 3. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) By enhancing the gap of the mesh structure of the polyester cloth, the intermediate layer and the base coating are fully infiltrated and integrated to effectively enhance the sealing performance of the coating. 4. Use steel coated excellent 1021 metal roof dedicated high-elastic waterproof coating (surface)

- Q: Light steel keel wall in the end is how much money to know

- Such a small area. But also deduction doors and windows. It is estimated that many people are willing to do. Beijing's labor costs are also high. Generally cut off about 75 square meters.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: Gypsum board wall above the good paint glass?

- You said it is necessary to nail fixed it, should not be installed, mainly afraid of bearing no, long-term bearing gypsum board may not stand, as far as I know gypsum board wall generally do not do curtains, No, I think you said the weight of the paint glass is not light, it should not work, not installed.

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- Gypsum board at the end of the seams should be open groove, easy to capping processing. Gypsum board edge joints should be in accordance with the provisions of the process.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Are environmentally friendly materials, the state provides the use of materials, but the high cost. There I do not know, I was in Hebei, are generally in our side of the transfer of goods in the past with.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

Send your message to us

Drywall Metal Profile of Stud Zinc Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords