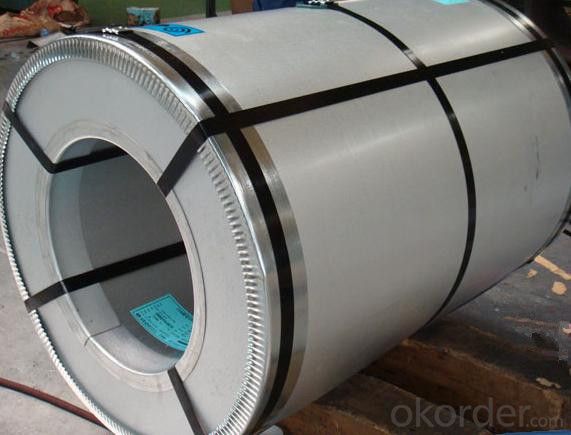

Zinc Coated Gi Galvanized Steel Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:roofing sheet

Surface Treatment:Galvanized

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS, GOST

Steel Grade:Q235

Grade:Dx51d / Dx52d/ Dx53D/ S250,280,320gd

Width:914, 1000, 1200, 1219, 1220, 1250

Base Material:Galvanized or Gavalume, Steel

Thickness:0.14mm to 1.5mm

Zinc Coating:40-150GSM

Length:up to The Thickness

Lacquer:Top Side15-25 Micro,Back Side 5 Micro

Surface:Passivation Unoiled Free Spangle Passivated

Export Markets:Global

Additional Info.

Trademark:STW or OEM

Packing:Export Seaworthy Packing

Standard:According to Your Requirement

Production Capacity:20000 Metric Tons/Month

Product Description

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight:4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

| MOQ | 50MT |

| What knid of color we can offer | RAL not only RAL, we can provide the color according to customer' s sample |

| What is the paint? | PE, PVDF |

| What is the original material for color-coated coil? Galvanized steel coil/cold rolled coill? | PPGI(raw material GI), GI(raw material CRC) CRC( raw material HRC) |

| Surface | Regular/mini/zero spangle, chromated, skin pass, dry etc. |

| Coil Inner Diameter | 508mm |

| Strength of material ? | G550= 550 mpa, normally around 280 mpa |

| what is the range of width we can do | 750mm, 762mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm |

| Thickness of the zinc coating | Z40 to Z275 |

| which color is most popular? | Blue in China, brown, red, green in oversea market |

| The weight of each coils? | Normally 5Tons. We can customized 3-6Tons |

| What is the leadtime? | Normally for coils we can delivery it within 25-30 days. Depends on the quantity |

| How many years of the paint would be lasting? | Different zinc, paint coating would lead to different result, and the environment has great impact on the life time of painting. |

| Applications | With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect. |

- Q: What are the different methods of coil rewinding for steel coils?

- Coil rewinding for steel coils can be approached in various ways, each with its own merits and considerations. One frequently employed technique is the slitting and rewinding process. This entails slicing the original steel coil into narrower strips, commonly known as "slits," and then winding these slits onto separate reels. Slitting and rewinding grants the ability to customize the width of the coil, making it popular in industries like automotive, construction, and packaging. Another method is oscillate winding. This approach involves rewinding the steel coil in a back-and-forth manner, resulting in a tighter and more compact coil. Oscillate winding proves particularly advantageous in reducing coil deformation during transportation and storage, as well as optimizing material usage. Additionally, the pancake coil winding method finds frequent use for steel coils. This technique involves rewinding the steel coil in a flat, pancake-like shape, making it easier to process and handle. Pancake coils are often employed in applications where space is limited, such as electrical transformers. Furthermore, advanced coil rewinding methods make use of automated equipment, such as robotic systems or computer-controlled winding machines. These technologies ensure precise and consistent rewinding, minimizing human error and enhancing overall efficiency. Ultimately, the choice of coil rewinding method hinges on the specific requirements of the application, including coil dimensions, material properties, and desired production output. Manufacturers must thoughtfully consider factors like coil quality, cost-effectiveness, and equipment capabilities when deciding on the most suitable method for their steel coil rewinding process.

- Q: 3 bedroom rambler with attached garage. A bad hail storm in May damaged my white siding and roof. I am concerned insurance adjustThanks much.er will not give me replacement value for steel siding. Any one know the cost and where to buy in Minnesota.

- I'm not sure of the cost but from experience having bought steel siding instead of vinyl for my home, if you can afford the difference it is well worth your money..I've had it for 25 years and it does hold up much better than vinyl!

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: What is the size range of steel coils?

- The size of steel coils can vary depending on the specific application and industry, offering a wide range of options. Steel coils are available in various sizes to meet different needs. The width of steel coils can range from a few inches to several feet, accommodating different requirements. Similarly, the thickness of steel coils can vary from very thin gauges, like 0.005 inches, to thicker gauges that exceed 0.5 inches. The length of steel coils is typically determined by the manufacturing process, but it can be customized to meet specific demands. In general, the size range of steel coils is extensive, providing flexibility and adaptability in industries like automotive, construction, and manufacturing.

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin.

- Q: What is the role of steel coils in the production of storage tanks?

- Steel coils play a crucial role in the production of storage tanks as they are used to construct the cylindrical body of the tank. These coils are cut and shaped into the desired dimensions and then welded together to create a strong and durable structure. The high strength and corrosion resistance properties of steel make it an ideal material for storage tanks, ensuring the safety and longevity of the tanks in various industries such as oil and gas, chemical, and water storage.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- If you are changing cook ware to improve your health, don't go with non-stick, because you will eventually be ingesting all that coating. The best cookware is cast iron, and the next best is stainless steel. The idea behind this recommendation is to reduce as many stresses on your immune system, so your systems can help you heal. There may be lots of other things you can do to eliminate chemicals and toxins from your house and food, so start with one thing at a time. Get some stainless steel mixing bowls, one stainless steel pot to boil water in, and then look into eating more raw foods. Use your blender and broiler. Good luck. I believe you can heal following eliminating the toxins from your house and food.

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- Stainless Steel does not rust...that is why it is used in our kitchens and the top kitchens of the world...!! sorry...Stainless Steel does not Tarnish either!

- Q: What's the best way to clean granite countertops and stainless steel appliances? My countertops especially always look dull and streaky. Thanks!!!!!!!

- Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing. :) Don't use an ordinary kitchen cleaning product to clean granite. The newest technology uses peroxide and detergents to penetrate soiled areas. Simply spray a product such as Bio-OX Citrus Concentrate on the soiled area, allow it to penetrate for a few minutes, then wipe clean. Baking soda can be sprinkled on for a more abrasive cleaning action. Repeat if necessary. Granite can also be cleaned using warm, sudsy water (a mild detergent such as a grease cutting dish detergent or laundry detergent is fine) or a solution of borax and water. Thoroughly rinse and buff dry. To remove stains from granite, make a paste of baking soda and hydrogen peroxide or baking soda and Bio-OX Citrus Concentrate and cover the stain with the paste. Cover the paste with a damp cloth, leave overnight, then wet down and scrub with a nonmetallic scrubbing pad. Rinse thoroughly with clean water. Wipe up any spills as they happen so they don't soak in, and always dry coutertops after washing the dishes.

- Q: How do steel coils contribute to the sustainability of construction projects?

- Steel coils contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material. Steel coils are manufactured to withstand extreme weather conditions, corrosion, and other external factors, making them ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, thus minimizing waste and resource consumption over time. Additionally, steel coils are recyclable. At the end of their lifespan in a construction project, steel coils can be easily and efficiently recycled. This process requires less energy compared to the production of new steel, resulting in reduced carbon emissions and environmental impact. Moreover, the recycled steel can be used in various industries, including construction, further promoting sustainability and resource conservation. Furthermore, steel coils contribute to the sustainability of construction projects by offering design flexibility. Steel is a versatile material that can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Additionally, the lightweight nature of steel coils allows for ease of transportation and installation, further reducing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Steel is an excellent conductor of heat and electricity, making it ideal for energy-efficient buildings. Steel coils can be used in the construction of walls, roofs, and other components that help to insulate buildings and reduce energy consumption for heating and cooling. This results in lower energy bills for the occupants and reduces the overall carbon footprint of the construction project. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By using steel coils, construction projects can reduce waste, conserve resources, minimize environmental impact, and optimize energy consumption, thus promoting a more sustainable and environmentally friendly approach to construction.

Send your message to us

Zinc Coated Gi Galvanized Steel Coil for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords