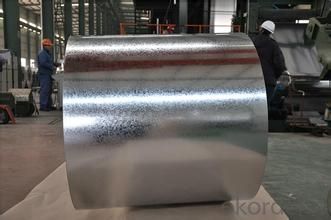

Hot-Dip Galvanized/ Aluzinc steel in Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Images:

Applications:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

- Q: What are some characteristics of steel.

- Characteristics Of Steel Hardening. - The characteristic difference between steel and pure wrought iron is as follows: - When steel is raised to a red heat and then suddenly cooled, it becomes hard and brittle. This process, which is known as hardening, has no effect upon pure wrought iron. Tempering is a characteristic of steel which distinguishes it from cast iron. If steel has been hardened by being heated and suddenly cooled, as above described, it may be softened again by applying a lower degree of heat and again cooling. This is known as tempering. Cast iron, on the contrary, though it is hardened by the first process, cannot be softened by the second. When a bar of steel is struck it gives out a sharp metallic ring, quite different from the sound produced by striking wrought iron. Other characteristics of steel are its great elasticity and its retention of magnetism.

- Q: What are they worth today? As well as a 1943 steel nickel?

- I think they are worth about a pennie.

- Q: I heard on some shows that you can carbonise steel by heating it red hot then dropping it in black oil. i cant find this no where online, and the process for commercial carbon steel is totally different. can you really carbonise regular steel by heating it to red hot then dropping it in regular black oil. i saw it on mythbusters once. when the made carbon steel hammers to test if 2 hammers smashed together will shatter

- Carburized steel is not the same thing as carbon steel. All steel has carbon in it, but carbon steel is defined as Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 1.04 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. Carburizing is a surface treatment. Dropping hot steel in oil is oil quenching. It might get a little carbon in the surface, but oil quenching is mainly used as a slightly slower quenching process than water quenching, not for carburizing. Once it starts cooling down the carbon won't diffuse in. Quenching is used to change the hardness. The simplest way to carburize steel is to pack charcoal around it and heat it to 900 C or so. Industrial processes use a gas like carbon monoxide, but that's mostly just for easier process control.

- Q: How are steel coils used in the production of metal fencing?

- Steel coils are used in the production of metal fencing as they serve as the raw material for manufacturing the fence panels and posts. The steel coils are typically flattened, cut, and shaped into various components, such as wires or sheets, which are then assembled to create the final fencing product. The durability and strength of steel make it an ideal material for fencing, ensuring the fence's ability to withstand external forces while providing security and boundary demarcation.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: How are steel coils processed for different finishes?

- Steel coils are processed for different finishes through various techniques such as hot rolling, cold rolling, pickling, and coating. Hot rolling involves heating the steel coils and passing them through rollers to achieve desired thickness and shape. Cold rolling further enhances the surface finish by reducing thickness and increasing strength. Pickling involves removing impurities and scale from the surface of the steel coils using acid solutions. Finally, coating techniques like galvanization or painting are used to provide protective and decorative finishes to the steel coils.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- Metagross would help out a lot, Excadrill id you are not doing double battles... (two of his best moves for him hit his team and are ground.. ) if you do not want to rick excadrill use a Lucario instead for hs massive damage output.

- Q: How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through a series of rigorous tests. These tests typically include tension tests, bend tests, and hardness tests. Additionally, the coils may undergo impact tests to evaluate their resistance to sudden forces. These tests help ensure that the steel coils meet the required standards and can withstand various conditions and applications.

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: How are steel coils used in the production of roofing panels?

- Steel coils are used in the production of roofing panels by being fed through a machine that shapes and cuts the steel into the desired panel size and shape. The coils are unrolled and flattened, then passed through a series of rollers to form the corrugated or flat panel profile. This process ensures the panels have the strength and durability required for roofing applications.

Send your message to us

Hot-Dip Galvanized/ Aluzinc steel in Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords