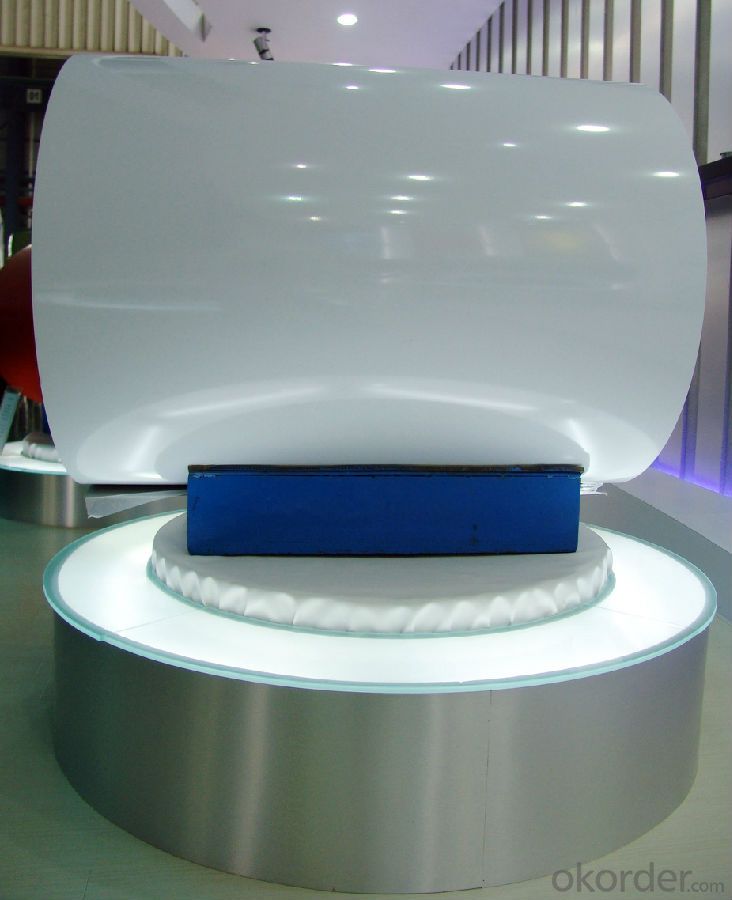

Galvalume Steel Coil/Gl/Zinc Aluminized Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specification:

| Product Name: | Galvalume steel coil/GL/Zinc Aluminized steel |

Standard: | JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB |

| Price: | US $600-800 / Metric Ton |

| Trade Terms: | FOB/CNF/CIF |

| Supply Ability: | 30000 Metric Ton monthly |

| Packing: | standard exporting packing or at buyer's requirement |

| Payment Terms: | L/C,T/T |

| Delivery time: | Within 15-30days after we receive deposit or L/C at sight |

| Specifications: | Brand Name :CNBM Thickness:0.14-0.6mm Type:coil/sheet/strips Width:600- 1250mm Length: Zinc Coating:40g-150g/ Coil ID :508mm or 601mm Coil Weight :3-8MT Place of Origin:China Tianjing,shanghai Standard: AISI, ASTM, BS, DIN, GB, JIS Technique:Cold Rolled Surface Treatment:Anti-finger |

Application

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Service

1.MOQ:25 ton.

2.Delivery time;15-30days

3.Payment:30% deposite, 70% in L/C before delivery or T/T

4.We can guarantee 100% inspeciton before the shipment

5.We can 100% supply MTC.

Q&A What is your acceptable payment term?

ANSWER: TT,LC,OA etc

- Q: What is the maximum temperature that steel coils can withstand?

- The maximum temperature that steel coils can withstand typically depends on the grade of steel being used. However, in general, steel coils can withstand temperatures up to around 1,200 to 1,300 degrees Celsius (2,192 to 2,372 degrees Fahrenheit) before they start to lose their structural integrity.

- Q: Ok I know this sounds stupid but is there anyway to make stainless steel look older? It looks too new and I don't want it like that. Thanks.

- Just abuse it. You could hit with a hammer, expose it to flame, throw it at or grind it around on rocks or concrete, rub it with steel wool. (be artful in how you do this, the pattern could end up looking too deliberate if you're not careful.) For an example of naturally aged stainless steel, look at some cooking pots/pans. If you don't have any old ones, maybe your parents or someone you know does. They usually get a little banged up/scuffed/stained after a while. (I think the stainless just means it doesn't rust.)

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components as they are typically used to form and shape various structural elements such as beams, columns, and trusses. These coils are unwound, flattened, and then processed through a series of machinery to be cut, shaped, and welded into the desired structural component. The steel coils provide a reliable and strong material base for the manufacturing process, ensuring the durability and stability of the final structural components.

- Q: How are steel coils used in the production of electrical relays?

- Steel coils are used in the production of electrical relays as they provide the necessary magnetic field required for the relay to function. When an electric current passes through the coil, it generates a magnetic field, which then attracts or repels the relay's switch mechanism. This coil-based mechanism allows relays to control the flow of electricity in various electrical circuits.

- Q: Can steel coils be returned if they are damaged?

- Yes, steel coils can be returned if they are damaged. Most suppliers and manufacturers have return policies in place for damaged goods, including steel coils. It is important to contact the supplier or manufacturer promptly and provide documentation or evidence of the damage to initiate the return process.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment as they are formed and shaped into various components such as vehicle frames, bodies, and structural parts. These coils provide the necessary strength and durability required for manufacturing automobiles, trains, ships, and airplanes.

- Q: If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- also add to answers above (now below), zincs are mounted on the hull and shaft to draw the electrolysis to them instead of the hull and are easily replaced by a competent diver

- Q: I have heard that heating the steel and applying oil will help with corrosion, and will give that aged look. I would like to know finishes available without painting. thanks

- No, I don't think the oil will do what you want. I have heated and quenched metal in oil several times (to harden it) and it did not give a finish to steel. I have heard of heating steel to a high temperature (red) and putting powdered sulfur on it, it will make a black finish. BUT, sulfur stinks and you would not do this indoors. And I don't know what the results would be like for indoor use. At the hardware store, you can find something like POR (paint on rust), a brand name of rust neutralizer. There are others. You spray it on (or paint) and it will turn rust into a glossy black material. Other than that, I think paint is your best option. Check out the new finishes they have now, if you haven't checked, they have come a long way. If you let them dry completely (in the sun) the spray can finishes are very durable. Good luck! Ooops, I forgot about gun finishes. Yes, some are blue, you might be thinking of that, but that is only if you put several coats on. One coat might do it. Plus, there are other colors, such as black (see the parkerizing link on the list). Here is a good company, they can be lots of help, too.

- Q: How are steel coils cleaned before use?

- Before being used, steel coils undergo a process called pickling to ensure their cleanliness. Pickling is a chemical treatment that eliminates impurities, scale, rust, and other contaminants from the surface of the coils. Initially, the coils are immersed in an acid bath, typically containing a mixture of hydrochloric acid and sulfuric acid. This acid solution effectively dissolves any rust, scale, and impurities present on the surface. The duration of immersion varies depending on the level of contamination and the desired level of cleanliness. After pickling, the coils undergo a thorough rinsing with water to eliminate the acid solution and any remaining residue. This step is crucial to prevent further corrosion or chemical reactions. Once rinsed, the coils are often dried to remove any remaining moisture. This can be achieved through air drying, using high-pressure air blowers, or passing the coils through heated chambers. After the cleaning process, the steel coils are now ready for use in various applications, such as manufacturing, construction, or any industry that requires high-quality steel products. The pickling process guarantees that the coils have a clean, smooth, and corrosion-resistant surface, enabling them to perform effectively and meet the desired specifications.

- Q: With the Reduced weight of steel,wouldn't the projectile be at a much higher velocity when fired causing more damage?I mean l couldn't steel be worked to seal the bore,not damage the rifling and still cheap enough to mass produce,and be light enough to carry much more ammo.

- Okay one side note before going into the main issue. Steel is really really hard on rifle barrels. Okay, so the most common lead 9mm bullet weighs 124 grains. If all that was wanted was higher velocity, you could switch to a 115 grain bullet (which some people do), or even a 90 grain bullet if you are a reloader. (You see 90 grain bullets for 380 acp ammo, that same bullet could be reloaded onto a 9mm cartridge) But velocity alone doesn't give power. That's why a 115 grain 9mm bullet going at it's standard velocity does less damage than a 45 acp's 230 grain bullet going at it's standard velocity, because it weights twice as much and yet is going only a little bit slower But now go out to your front yard and grab a ping-pong ball and a rock about the same size. Throw them both as hard as you can. The ping-pong ball while lighter didn't go very far did it. See, the ratio of surface area to overall weight of ping-pong ball is very high, so air resistance works on it a LOT. And that is what makes lead so great for projectiles. It is dense so you have a very small surface area per unit of weight meaning that a steel bullet may beat lead in initial velocity but just 50 feet out the lead bullet would be going pretty much the same speed and at 100 yards out the steel would be dramatically slower. Note this is the same reason why 'secret sniper ice bullets' would never work even if you could get it to not melt...it's just too light. Ever hear of tanks and airplanes firing DU ammo? That stands for Depleted Uranium, it is something that is even more dense than lead which is why it makes an even better bullet than lead

Send your message to us

Galvalume Steel Coil/Gl/Zinc Aluminized Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords