Zinc Coated Galvanized Treatment Steel Coil Z275

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

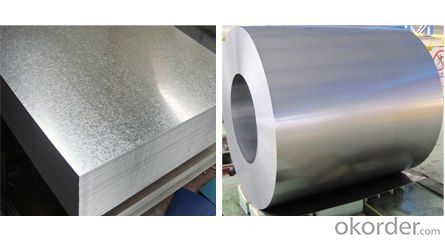

Zinc Coated Galvanized Treatment Steel Coil Z275

Main Structure of Zinc Coated Steel Coil

1.Thickness:0.14-2.5mm

2.Width:600-1250mm

3.Grade:SGCC,JISG3302,DX51D,Q235

4.Zinc Coating:60-275g/m2

5.Coil ID:508mm/610mm

6.Coil weight:3-8ton

Specification for Zinc Coated Steel Coil

| Commodity | China Manufacture High quality Galvanized Steel Coil |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-2.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20'containers |

| Application: | Industrial panels, roofing and siding for painting |

Application of Zinc Coated Steel Coil

Construction usage

Storage usage like steel silo, grain storage silo

Building material

Industrial using

Picture:

- Q: How are steel coils used in the production of metal staircases?

- Steel coils are an essential component in the production of metal staircases. These coils, typically made of high-quality carbon steel, are first uncoiled and then go through a series of manufacturing processes to shape them into the required stair components. The first step in the production process involves cutting the steel coils into the desired lengths using specialized machinery. This allows for customized sizing to fit the specific staircase design. Once cut, the coils are then formed into various shapes and profiles, such as stringers, treads, and risers, through processes like bending, rolling, and stamping. The use of steel coils provides several advantages in the production of metal staircases. Firstly, steel is known for its strength and durability, making it an ideal material choice for staircases that need to withstand heavy loads and frequent use. The flexibility of steel coils allows for the creation of intricate and complex staircase designs, providing architects and designers with a wide range of options. Furthermore, steel coils can be coated or finished in various ways to enhance their appearance and protect them from corrosion. This can include painting, powder coating, or applying a protective layer such as galvanization. These finishes not only add aesthetic value to the metal staircases but also increase their longevity and resistance to wear and tear. In summary, steel coils are integral to the production of metal staircases as they provide the raw material that is shaped and formed into the necessary components. Their strength, flexibility, and ability to be finished in different ways make steel coils a versatile and reliable choice for manufacturing durable and visually appealing staircases.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- another name is Grey iron, come from groups of ferrous alloys

- Q: Can steel coils be coated with PVC?

- Yes, steel coils can be coated with PVC. PVC coating provides added protection against corrosion and increases durability and longevity of the steel coils.

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel coils have a longer lifespan and require fewer repairs and replacements. This reduces the overall environmental impact associated with construction activities. Additionally, steel is a highly recyclable material, with most steel coils containing a significant amount of recycled content. This promotes a circular economy and reduces the demand for new raw materials. Moreover, steel coils are lightweight and versatile, allowing for more efficient transportation and installation, thereby reducing energy consumption and emissions during construction. Overall, the use of steel coils in construction promotes sustainability by offering durability, recyclability, and energy efficiency.

- Q: What are the different coating options for steel coils?

- Steel coils have multiple options for coating, each with its own purpose and benefits. Some commonly used coatings for steel coils include the following: 1. Galvanized Coating: Steel coils are immersed in molten zinc, resulting in a zinc layer on the surface. This coating offers excellent corrosion resistance and protects against rust. It is ideal for harsh environments and moisture exposure. 2. Galvannealed Coating: This coating combines galvanizing and annealing processes. After galvanizing, the steel coils are annealed to create a zinc-iron alloy layer. Galvannealed coating provides enhanced paintability, weldability, and corrosion resistance. 3. Aluminum-Zinc Alloy Coating: Also known as Galvalume, this coating involves applying an aluminum-zinc alloy to the steel coils. It offers excellent corrosion resistance and heat reflectivity, making it suitable for roofing, siding, and automotive parts. 4. Organic Coatings: These coatings are typically applied as a top layer over a base coat of galvanized or galvannealed coating. Examples include paints, lacquers, and powder coatings. Organic coatings provide additional protection against corrosion, UV rays, and abrasion while enhancing the aesthetics of the steel coils. 5. Chromate Conversion Coating: This coating is commonly used as a pre-treatment before applying organic coatings. It improves adhesion between the steel surface and the organic coating, ensuring better corrosion resistance. The choice of coating depends on factors such as the intended application, environmental conditions, desired appearance, and budget. Manufacturers and end-users should carefully consider these factors to select the most suitable coating option for their specific requirements.

- Q: What are the different methods of coil joining for steel coils?

- There exists a variety of techniques for joining steel coils, each with its own advantages and limitations. Some commonly employed methods encompass the following: 1. Welding: Among the most popular methods of coil joining, welding involves the use of heat to melt and fuse the edges of steel coils. Arc welding, resistance welding, or laser welding can be utilized for this purpose. Welding offers a robust and durable joint, although it can be time-consuming and necessitate skilled operators. 2. Mechanical fastening: This technique entails the use of mechanical fasteners like clips, staples, or bolts to connect the edges of steel coils. Mechanical fastening is relatively quick and straightforward, and it allows for easy disassembly if needed. However, the joint may not be as strong as welding and can be prone to loosening over time. 3. Adhesive bonding: Adhesive bonding involves the use of a suitable adhesive or glue to bond the edges of steel coils. This approach yields a strong and uniform joint, while also providing protection against corrosion. However, adhesive bonding may require surface preparation and curing time, and it might not be suitable for high-temperature applications. 4. Interlocking or tongue-and-groove joints: This method involves shaping the edges of steel coils in a manner that they interlock or fit together like puzzle pieces. Interlocking joints provide good alignment and are easily assembled and disassembled. Nevertheless, they may not yield as strong a joint as welding or mechanical fastening. 5. Coil-overlapping: In this method, the edges of steel coils are overlapped and clamped together using mechanical means. Coil-overlapping is a simple and cost-effective technique, albeit it may not yield a strong joint and can result in uneven coil edges. When selecting the appropriate method of coil joining for steel coils, it is crucial to consider factors such as application requirements, strength requirements, cost, and production efficiency.

- Q: Can steel coils be used in the production of construction machinery?

- Indeed, the utilization of steel coils is applicable in the manufacturing process of construction machinery. Frequently, steel coils serve as the primary elements employed in the production of diverse components, including frames, chassis, gears, and structural parts for construction machinery. The exceptional strength and enduring nature of steel render it the perfect material for construction machinery, given its ability to withstand demanding operational conditions. Furthermore, steel coils offer effortless shaping, welding, and fabrication procedures to achieve the desired shapes and sizes, thereby providing customization and adaptability in the production of construction machinery.

- Q: How are steel coils used in the production of steel clamps?

- Steel coils are used in the production of steel clamps as the primary raw material. The coils are fed into a machine that cuts, shapes, and bends them to create the desired clamp design. The strength and durability of the steel coils ensure that the resulting clamps are capable of securely holding objects together.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is in history books only,no body knows its composition.THey just named a modern steel as Damascus steel

- Q: A 100 kg solid steel ball with a radius of 5 m is being spun on ice with an angular velocity of 5 rev/s pointed into the ice (clockwise rotation when viewed from above).A student shoots a 10 kg marble at the steel ball. The marble hits the ball along its side as shown with an initial velocity of 5 m/s to the left. If, right after the collision, the final velocity of the marble is 2.5 m/s to the left, what is the angular velocity of the steel ball after the collision?

- You need to do conservation of angular momentum about the steel ball's axis. Angular momentum = I.ω The steel ball's initial ω = 5 rev/s = 5*2pi rad/s = 31.4 rad/s The steel ball's moment of inertia I = (2/5)*m*r^2 = 40*25 kg.m^2 = 1000 kg.m^2 The marble's initial ω = v / r where r is the perpendicular distance from the steel ball's axis You need to look at the diagram for this. The marble's I about the steel ball's axis is I = m*r^2 where r is the same as above. (marble is treated as a point mass). Then work out the total initial ang. momentum = final ang. momentum and solve for ω...

Send your message to us

Zinc Coated Galvanized Treatment Steel Coil Z275

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords