Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil:

Galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments. Steel coil of any kind is flat stock that is thin enough to be rolled into a coil or wound into a continuous roll. It is also able to be rolled out flat and cut at any length or shape needed. Having the steel coil galvanized helps the user by allowing it to be applied in outdoor fabrication projects.

2.Specifications of Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil:

1)Standard: AISI,ASTM,BS,GB,JIS

2)Grade:SGCC,DC51D,DX51D,DX52D,SPCC,SGCD,Q235,SGHC, G350…

3)Thickness: 0.14mm-2.5mm

4)Width: 100mm -600mm, 600mm-1500mm,762mm,914mm,1000mm,1200mm,1219mm,1250mm.

5)Length: 1000-6000mm or as customer’s requirement

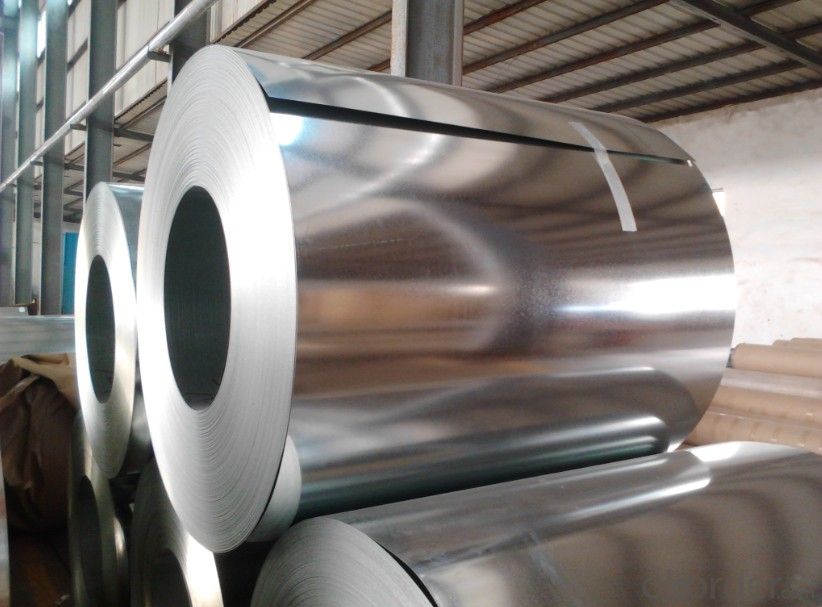

3.Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil Images:

4.Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil Specification:

Trade information | ||

Technique | cold rolled | |

Standard | ASTM A653-2001,DIN10142-91,DIN1012--92, EN10327,JISG3302-2005,GB/T2518-2004 | |

Surface Treatment | Galvanized(Zinc 60—275g/m2)Oil,chromated as your requirement | |

Coil ID | 508mm/610mm | |

MOQ | 20 metric tons or negotiation | |

Package | Export standard package | |

Delivery Time | According to the order quantity | |

Trade Terms | FOB,CFR or CIF | |

Payment Term | T/T or L/C at sight | |

5.Our factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Having a greater amount than 2% carbon in steel causes steel to suddenly become brittle. Why is this?

- Carbon fiber has better tensile capability then steel meaning its better while pulled aside. Plus you could mould the fiber to make autos-or homes-out of carbon fiber.

- Q: What are the different coil coating options available for steel coils?

- There are several coil coating options available for steel coils, including polyester, polyurethane, fluoropolymer, silicone polyester, and plastisol coatings. Each of these options offers different properties such as durability, weather resistance, UV protection, and chemical resistance, allowing for customization based on the specific application and environmental conditions.

- Q: What are the different methods of uncoiling steel coils?

- There are several methods used for uncoiling steel coils, including hydraulic uncoiling, motorized uncoiling, and manual uncoiling. Hydraulic uncoiling involves using hydraulic cylinders to unwind and release the tension in the coil. Motorized uncoiling utilizes a motorized mandrel or decoiler to unwind the coil. Manual uncoiling, on the other hand, requires physical effort to unwind the coil by hand. Each method has its own advantages and is chosen based on the specific requirements and capabilities of the uncoiling process.

- Q: Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- The term tensile potential refers back to the quantity of tensile (stretching) rigidity a textile can stand up to in the previous breaking or failing. the in simple terms suitable tensile potential of a textile is calculated by making use of dividing the element of the textile examined (the pass area) by making use of the strain located on the textile, regularly expressed in terms of pounds or much consistent with sq. inch of fabric. Tensile potential is an considerable degree of a textile's skill to accomplish in an utility, and the scale is extensively used whilst describing the residences of metals and alloys.

- Q: Can steel coils be coated with self-cleaning materials?

- Yes, steel coils can be coated with self-cleaning materials. These materials are typically hydrophobic or photocatalytic coatings that help prevent dirt, dust, and other contaminants from sticking to the surface of the steel. The self-cleaning properties of these coatings allow for easier maintenance and longer-lasting aesthetics of the steel coils.

- Q: How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers to provide strength and durability. The coils are shaped into various components of the trailer's structure, such as the frame and chassis. This ensures that the trailer can withstand heavy loads and rough terrain, making it suitable for transporting agricultural equipment and produce.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Someone stated even the $99 walmart bikes are aluminum now. WRONG! Most Walmart bikes have steel frames unless you drop about $200.00. Personally, I prefer aluminum over steel. It's lighter, most times - just as strong and won't rust if you get a ding or scrape in the paint. See links below on Trek M/B. Trek 820 - steel frame - $329.99. Trek 3500 - aluminum frame - $359.99.

- Q: How do steel coils contribute to the automotive industry?

- Steel coils are a crucial component in the automotive industry as they are used to manufacture various parts of vehicles, including the body frame, doors, hoods, and chassis. The high strength and durability of steel coils make them ideal for enhancing the safety, structural integrity, and overall performance of automobiles. Additionally, steel coils are cost-effective, readily available, and can be easily formed into different shapes and sizes, making them an essential material in the production of cars and trucks.

- Q: How do steel coils impact the overall cost of production?

- Steel coils have a significant impact on the overall cost of production in a variety of industries. Firstly, the cost of steel coils themselves can be a significant expense. The price of steel is influenced by various factors such as supply and demand, raw material costs, and market fluctuations. Any increase in the cost of steel coils can directly impact the overall production cost, as it becomes a major component in the manufacturing process. Moreover, steel coils also affect the operational costs of production. They are typically used in various manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The durability, quality, and size of the steel coils play a vital role in determining the efficiency and effectiveness of these processes. If the steel coils are of low quality or not suitable for the specific production requirements, it can lead to increased downtime, machinery maintenance, and rework, all of which contribute to higher production costs. In addition, transportation costs associated with steel coils can also impact the overall cost of production. Steel coils are usually heavy and bulky, necessitating special handling and transportation arrangements. The distance between the supplier and the production facility, as well as the mode of transportation, can significantly influence the logistics costs. Any increase in transportation expenses, such as fuel prices or shipping fees, can directly impact the overall cost of production. Lastly, the availability of steel coils can also impact production costs. In times of high demand or limited supply, the price of steel coils may increase, leading to higher production costs. Furthermore, if there is a shortage of steel coils due to factors like trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or lower in quality. These factors can have a cascading effect on the overall cost of production. Overall, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers need to carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q: How are steel coils used in the production of metal roofing panels?

- Steel coils are used in the production of metal roofing panels by being unrolled and fed through a rolling machine that shapes and forms the metal into the desired panel shape. This allows for efficient and precise manufacturing of metal roofing panels, which are then used for construction purposes.

Send your message to us

Hot Dipped Galvanized Steel Coil Z275/Zinc Coated Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords