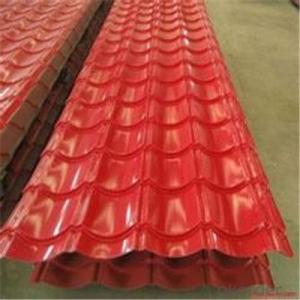

Zinc Aluminum Roofing Sheets - Aluminium Chequered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum sheet/coil (DC line) 5000series

1) Alloy:5005,5052,5083,5251,5754

2) Temper: Various status

3) Thickness:0.3-150mm

Aluminum sheet/coil (CC And DC )

1) Alloy: 1000series, 3000series, 5000series

2) Temper: Various status

3) Thickness:0.3-350mm

4) Width:300-1600mm

5) Weight: 2.5-5.0 tons per coil

6) Length: Under9500mm/ Coil

7) Inner Diameter: 505mm,605mm

8) Dimensions and weight can be produced according to clients' specifications.

9) Packing: Export standard, wooden pallet.

10) Delivery time: 30 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Mill finish

14) Origin: China

Thickness Specifications: 0.3mm---150mm

Width Specifications: 300mm---1950 mm

Length Specifications: Under9500mm/ Coil

- Q: I am thinking about getting a MacBook Aluminum or a MacBook white. The Aluminum is 2.0 GhZ and the MacBook White is 2.16 GhZ. which should i get? also i am really wondering if you can upgrade the processors in both MacBooks..... Please give me link if you can. THANKS!!

- If okorder /... I'm not sure about the processor's. I dont use Mac that often!

- Q: what’s the difference of activated aluminum and aluminum sheet?

- contain more water and activated

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- Cryogenic applications are not suitable for 101 aluminum sheets. Although aluminum is generally a good choice for low-temperature environments because of its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to endure the extreme temperatures associated with cryogenic applications. In cryogenic applications, materials like aluminum alloys (for example, 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are commonly used. These materials possess improved properties that allow them to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is advisable to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q: Are aluminum sheets suitable for roofing?

- Indeed, aluminum sheets prove to be a fitting choice for roofing purposes. Renowned for its lightweight nature, durability, and corrosion resistance, aluminum stands out as a favored material in the roofing industry. Moreover, its non-combustible properties render it a safer alternative. The ease of installation and maintenance further add to its appeal, as do its ability to withstand adverse weather conditions like heavy rain, snow, and wind. Notably, aluminum also earns accolades as an environmentally conscious option, boasting 100% recyclability. In summary, aluminum sheets offer a trustworthy and enduring roofing solution for both residential and commercial edifices.

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- There are several different types of surface treatments available for architectural aluminum sheets. These treatments are designed to enhance the appearance, durability, and performance of the aluminum, making it suitable for a wide range of architectural applications. One common type of surface treatment is anodizing. Anodizing involves immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed to achieve a desired color or left clear for a natural metallic appearance. Anodized aluminum sheets are known for their excellent corrosion resistance, scratch resistance, and color stability. Another type of surface treatment is powder coating. Powder coating involves applying a dry powder electrostatically to the aluminum sheet and then curing it in an oven. The powder melts and fuses to the surface, creating a smooth and durable finish. Powder coating provides excellent color retention, weather resistance, and resistance to chipping and cracking. A third type of surface treatment is PVDF coating. PVDF (polyvinylidene fluoride) coating is a high-performance fluoropolymer resin that is applied to the aluminum sheet through a coil coating process. PVDF coatings offer exceptional resistance to fading, chalking, and chemical attack, making them ideal for exterior applications where color retention and durability are key. Additionally, there are various mechanical surface treatments available for architectural aluminum sheets. These treatments, such as brushing or polishing, can provide a desired texture or reflectivity to the surface. Mechanical treatments can be used to create a brushed, satin, or mirror-like finish, adding aesthetic appeal to the aluminum sheet. In summary, the different types of surface treatments available for architectural aluminum sheets include anodizing, powder coating, PVDF coating, and mechanical treatments. Each treatment offers unique benefits and characteristics, allowing architects and designers to choose the most suitable option for their specific project requirements.

- Q: Is the chemical formula for Aluminum Sulfate Al2(SO4)3?How and why is Al2(SO4)3 wrong?

- Aluminum Sulfate Formula

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: How many atoms are in a 2.80 cm* 2.80cm*2.80cm cube of aluminum?

- 2.8cm * 2.8cm * 2.8cm= 21.95 cm^3 is volume of Aluminum present Density of Al = 2.7g/cm^3 Convert volume of aluminum into grams of Aluminum, make sure your units cancel 21.95 cm^3 * (2.7g/1 cm^3) = 59.26 g Al Next, find how many moles of Al you have. MW Al = 27g/mol 59.26/27 = 2.19 moles Al Use Avogadro's number to find number of atoms of Al - 2.19 moles Al * (6.022x10^23 atoms/1 mol Al) = 1.32x10^24 atoms Al

- Q: What is a composite aluminum plate?

- APCP (also called APCP) as a new type of decorative materials, since the last century at the end of 80s early 90s from South Korea to China, with its economy, optional color diversity, convenient construction method, excellent processing performance, excellent fire resistance and noble quality, quickly favored by people.Abroad, the name of aluminum plate has many kinds, there is called "aluminum composite board" (Aluminum Composite)Panels) there is called aluminum composite (Aluminum, Composite)Materials) in many European countries, the aluminum plate is Alucobond, a trademark derived from the aluminum-plastic plate. There are not many enterprises producing aluminum-plastic plate abroad, but the scale of production is very large. Well known are the Swiss based Alusuisse company and the Reynolds Metal Co in the United StatesJapan, Mitsubishi Co, Korea Daming, etc.. Taiwan auspicious, famous enterprises, Jiangxi Thailand, Alice Alex Hua Tian, Shanghai Huayuan, Ningbo aihome aluminum building materials.

- Q: What are some common applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these applications. 2. Automotive industry: Aluminum sheets are extensively used in the automotive industry to manufacture car bodies, panels, and components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel efficiency. 3. Packaging: Aluminum sheets are commonly used for packaging purposes, especially in the food and beverage industry. They are used to make cans, foils, and lids, thanks to their ability to preserve the freshness and quality of the packaged products. 4. Aerospace industry: Aluminum sheets play a vital role in the aerospace industry. They are used to manufacture aircraft bodies, wings, and structural components due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets are used in the electrical industry for various applications, including manufacturing electrical enclosures, transformers, and bus bars. Aluminum's excellent conductivity and lightweight nature make it a preferred choice for these applications. 6. Marine industry: Aluminum sheets are widely used in the marine industry for building boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and its ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are frequently used for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These are just a few examples of the common applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it a highly sought-after material in various industries.

Send your message to us

Zinc Aluminum Roofing Sheets - Aluminium Chequered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords