Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

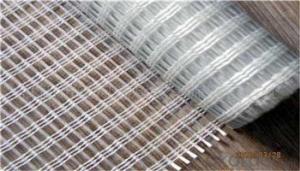

Structure of Fiberglass Cloth Description:

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

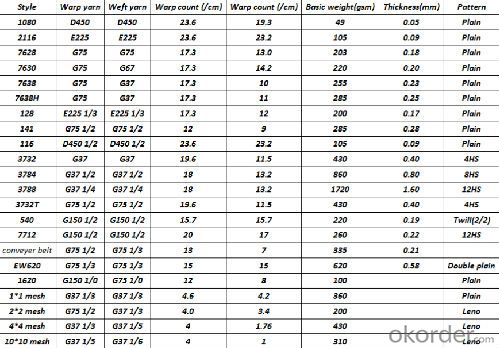

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How does fiberglass fabric perform in terms of mold and mildew resistance?

- The resistance of fiberglass fabric to mold and mildew is generally commendable. This can be attributed mainly to its non-porous nature, which prevents the absorption of moisture. Mold and mildew thrive in damp environments, so the moisture resistance of fiberglass fabric effectively hinders their growth. Moreover, fiberglass fabric is often treated with specialized coatings or finishes that further enhance its resistance to mold and mildew. These treatments form a protective barrier on the fabric's surface, making it more challenging for mold and mildew spores to attach and proliferate. However, it's important to note that although fiberglass fabric offers good resistance, it is not entirely immune to mold and mildew. If the fabric is exposed to excessive moisture or if it is not adequately cleaned and maintained, mold and mildew can still develop. Therefore, regular cleaning and proper care are crucial in preserving the mold and mildew resistance of fiberglass fabric.

- Q: Can fiberglass fabric be used for reinforcement in plastic parts?

- Yes, fiberglass fabric can be used for reinforcement in plastic parts. Fiberglass fabric is known for its high strength and durability, making it an ideal choice for reinforcing plastic components. When the fabric is embedded in plastic material, it adds strength, rigidity, and resistance to deformation. This reinforcement is particularly useful in applications where the plastic part needs to withstand heavy loads, impacts, or extreme temperatures. Additionally, fiberglass fabric can also improve the dimensional stability of plastic parts, reducing the risk of warping or distortion. Overall, fiberglass fabric is widely used in various industries to enhance the mechanical properties and performance of plastic parts.

- Q: Is fiberglass fabric resistant to flame spread?

- Indeed, flame spread is resisted by fiberglass fabric. This material is non-flammable and does not readily ignite. With a high ignition temperature and the inability to support combustion, fiberglass fabric finds extensive use in various applications that prioritize fire resistance. These include insulation materials, protective clothing, and fireproof curtains. Furthermore, fiberglass fabric exhibits exceptional durability even under extreme temperatures, rendering it an ideal option for environments where fire safety is paramount.

- Q: The pipe is too hot. What's the protection?

- Heat insulation cotton with high temperature resistance, easy combustion, low coefficient of heat conductivity, is now widely used in the insulation cotton industry is made of glass fiber and material processing, such as glass cotton, glass cotton.

- Q: Can fiberglass fabric be used in automotive applications?

- Fiberglass fabric is indeed applicable in automotive uses. This material is renowned for its strength, durability, and resistance to heat. It finds frequent use in various automotive elements, including body panels, hoods, fenders, and interior parts. Given its ability to be shaped into intricate forms and its exceptional structural properties, fiberglass fabric is ideal for automobile applications that prioritize strength and lightweight design. Moreover, it is effortless to paint and offers a sleek finish, ultimately enhancing the visual appeal of automotive components. All in all, fiberglass fabric is a highly favored option in the automotive industry due to its versatility, strength, and ability to meet the rigorous demands of automotive uses.

- Q: Can fiberglass fabrics be used for insulation in pipelines?

- Yes, fiberglass fabrics can be used for insulation in pipelines. Fiberglass fabrics have excellent thermal insulating properties as they can effectively prevent heat transfer. When used as insulation in pipelines, fiberglass fabrics can help to maintain the desired temperature of the fluid being transported, whether it is hot or cold. Additionally, fiberglass fabrics are resistant to moisture and chemicals, which makes them suitable for use in various environments. They are also lightweight and flexible, allowing for easy installation and maintenance. Overall, fiberglass fabrics are a popular choice for pipeline insulation due to their thermal insulation capabilities and durability.

- Q: What are the different weaving patterns available for fiberglass fabric?

- Fiberglass fabric comes in various weaving patterns, each with its distinct qualities and uses. The plain weave is the most fundamental and widely employed pattern. It involves a simple interlacing of warp and weft yarns, resulting in a balanced and uniform fabric structure. This type of fiberglass fabric offers good strength, dimensional stability, and versatility for different applications. Twill weave, on the other hand, creates a diagonal pattern on the fabric surface. By passing the weft yarn over multiple warp yarns before going under, this weaving technique enhances the fabric's drapability, flexibility, and ability to conform to complex shapes. Twill weave fiberglass fabric is commonly chosen for applications that require both durability and flexibility, such as in the aerospace and automotive industries. Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and glossy surface with reduced crimp and higher yarn density. Satin weave fiberglass fabric is known for its excellent drapeability, high strength-to-weight ratio, and is often used in industries that demand a high-quality surface finish, such as marine and sporting goods. Leno weave is a unique pattern where the warp yarns are twisted together, resulting in an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric finds utility in filtration, reinforcement in composites, and as a base fabric for laminates. Finally, jacquard weave is a complex pattern achieved by controlling each warp yarn individually. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. In conclusion, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each pattern brings unique characteristics and advantages, providing numerous possibilities for utilizing fiberglass fabric across various industries.

- Q: Are fiberglass fabrics suitable for use in the automotive industry?

- Yes, fiberglass fabrics are suitable for use in the automotive industry. Fiberglass fabrics offer several benefits that make them ideal for automotive applications. Firstly, fiberglass fabrics are known for their strength and durability. They have high tensile strength and are resistant to wear and tear, making them capable of withstanding the harsh conditions of the automotive environment. Fiberglass fabrics are also highly resistant to chemicals, moisture, and extreme temperatures, which further enhances their suitability for automotive use. Secondly, fiberglass fabrics are lightweight. This is a crucial characteristic for the automotive industry as it helps improve fuel efficiency and overall vehicle performance. By using fiberglass fabrics, manufacturers can reduce the weight of car components without compromising on strength and safety. Additionally, fiberglass fabrics have excellent thermal and electrical insulation properties. This makes them suitable for various applications in the automotive industry, such as insulation for engine compartments, exhaust systems, and electrical wiring. Furthermore, fiberglass fabrics can be molded into different shapes and sizes, allowing for customization and versatility in automotive design. They can be easily integrated into various components, including body panels, interior trims, and structural reinforcements. Overall, fiberglass fabrics offer a combination of strength, durability, lightweightness, insulation, and versatility, making them highly suitable for use in the automotive industry. They contribute to improved performance, fuel efficiency, and safety in vehicles, making them a popular choice among automotive manufacturers.

- Q: What are the differences in the quality and performance of domestic glass fiber cloth and imported fiberglass fabric?

- Domestic glass fiber: it is made up of two layers of non-woven fabric and three layers of glass fiber. The layer is not clear and the filter layer is thick. It is not easy to break the water in the oil. The precision is generally 1 - 100 microns

- Q: Can fiberglass fabric be used for insulation in underground structures?

- Indeed, insulation in underground structures can be achieved by utilizing fiberglass fabric. This fabric is highly favored for its exceptional thermal characteristics and ability to withstand moisture. It is widely employed in numerous applications, notably in underground structures like basements, tunnels, and underground storage facilities. Typically, the fabric is positioned as a layer between the structure's walls or ceiling and its interior finish, serving as a protective barrier that curbs heat loss or gain and promotes a pleasant temperature within the structure. Moreover, fiberglass fabric is renowned for its lightweight nature, flexibility, and simplicity of installation, rendering it a convenient choice for insulating subterranean spaces.

Send your message to us

Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords