Quick Details

Brand Name: Joen

Model Number: CW260

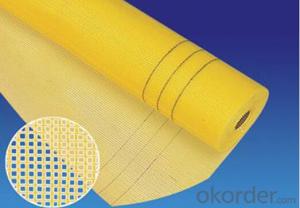

Application: Fiberglass Mesh Cloth

Weight: 98--1550g

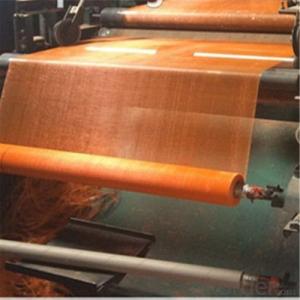

Surface Treatment: Silicon Coated

Width: 1-2m (customized)

Weave Type: Plain Woven

Yarn Type: C-Glass

Alkali Content: Medium

Standing Temperature: 550℃ (1000 ℉)

Color: white,golden