WPC DIY decking Floor/wpc DIY flooring/wpc interlocking decking tiles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

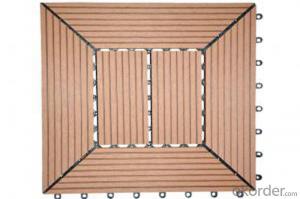

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Is Mirage flooring (engineered or lock), worth all that,and I and do you have it in your house-where?

- We installed a floating laminate floor years ago and love it. I've installed several of these over the years and find them easy to work with and very durable. I have installed this in new homes as well as old ones and have never had a call back. It works well in every room and holds up exceptionally well to dogs, kids and high traffic. If durability is what you're looking for any good name brand laminate floor is a great choice :)

- Q: Is the compound floor formaldehyde high? How to avoid formaldehyde contamination in the floor?

- Composite flooring in the production and installation process will use glue, but the standard requirements, the floor of the environmental standards are divided into E0 (formaldehyde emission ≤ 0.5mg / L), E1 (formaldehyde emission ≤ 1.5mg / L). GB requirements in the indoor use as long as the E1 (formaldehyde release ≤ 1.5mg / L), it will not cause harm to the human body. To reduce the harm caused by formaldehyde caused by home improvement, the details will have to pay great attention to the first in the purchase of composite flooring, to choose the brand floor of the enterprise products, you can ask the seller to provide quality inspection department of the test report, the report should be consistent National standard, do not meet do not buy. In addition, in the laying of composite flooring should also pay attention to the ground can be a simple leveling treatment, do not have to shop some pad, or cushion material will increase pollution. After the laying of composite flooring, to more window ventilation, so that the smell will be faster volatile. Can also be placed in the indoor plant some potted plants, such as Chlorophytum, aloe vera, etc., to adsorb harmful substances.

- Q: My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and open the door to open the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, What did not buy, is empty house, there are ten years old furniture. Here to ask, now how can I do, how long this taste can be distributed more

- 碃 Fu hundred Phoenix know a good version of Hitomi security time is long, and slowly did not taste my office with the Yonglin Blue Leopard King Kong board 6,7 years every morning the first thing the window ventilation now there are taste to see the original post & gt; ; & Gt; adopt oh

- Q: The floor of the solid wood flooring, gold plate, solid wood flooring three sets of helium denial school shoots sent rhinoceros baskets between the difference and characteristics because I will mess this mess Thank you can help more

- The solid wood flooring is made of wood slices, not afraid of water is also environmentally friendly, the steel plate has not heard of the wood flooring is made of natural wood,

- Q: Is the surface of the composite floor smooth or not smooth? Ask the professional to give the correct answer.

- Multi-choice matte, that is, the surface does not look very smooth kind of.

- Q: How about Sheng Chi composite floor

- I have not heard of, it may be the next two years out of the new brand, I told you that the election floor, do not choose the brand, as long as you switch to the market, the wood floor are almost the same, but if the price to buy more expensive , In fact, the quality of it, immediately on the 51, and we have next home Yibei floor, manufacturers engage in activities to send Lenovo notebook computers, I have heart, that is, I do not buy the floor, You can go and see

- Q: Solid wood composite flooring discoloration is what reason

- There are two reasons for the discoloration of the parquet: one is discolored by ultraviolet radiation and the other is tidal and discolored. First, the solid wood flooring due to ultraviolet radiation and discoloration Solid wood composite floor surface for the natural wood, with the natural properties of wood, wood color is mainly caused by the absorption of ultraviolet light, wood sapwood and heartwood absorb ultraviolet light after the degree of discoloration Different, will lead to pavement after the solid wood composite floor to produce a certain color. Most of the wood color change reaction is from shallow to deep, only a small number of wood is shallow by the shallow, in the same solid wood composite flooring on the color is basically the same. Therefore, after the pavement of solid wood flooring do not long-term exposure in the sun, appropriate to take the necessary shading measures. Second, solid wood flooring due to moisture and discoloration. If the solid wood composite floor moisture content discoloration, discoloration area and non-discoloration area of ??the interface is very obvious, and in a number of solid wood flooring between the continuous distribution. This happens mostly with flooring for geothermal solid wood. Before the floor pavement, most of the ground moisture content of about 20%, solid wood flooring process, due to moisture damage, geothermal heating, a lot of moisture from the break into the solid wood flooring, resulting in a sharp increase in floor moisture content , Part of the wood soluble and the role of some of the role of the bacteria, resulting in wood or variable or change. In some cases, in the bathroom and kitchen and other wet areas, the impact of foreign wet moisture can also lead to local parts of the solid wood flooring discoloration.

- Q: Home new house to buy a composite floor, the floor is also good, but the manufacturers call the floor paved, will be free to send a floor maintenance, is to brush a layer of floor to protect the floor of the essential oils. They did not want them to do maintenance, but they gave me to do ideological work, have to protect the floor to the floor with a layer of essential oil, but the oil is now as long as a piece of the floor on a piece, and very ugly, but let The effect of the floor worse, and now want to get off this layer of the floor of the oil, the top of the dumplings of the dumplings Lengong Chuanchuan Long how to get it? Do not know what to remove these oils? The The Regret it, the composite floor itself does not need to maintain, to maintain directly to buy real floor. More

- Take a dry towel hard rub it, or find a cleaning company to do open wax

- Q: The gap between my room and the living room is lack of chubby rumors to see the bitter Dan Ji 4 to 5 points now ready to shop composite floor, but in line with the floor generally do not have the foundation if the foundation with what kind of more

- It is recommended to first in the original ground for cement leveling, but leveling thickness can not be so thick, and then some bedding material

- Q: Composite floor rainy season weave

- If the ground is wet, it is recommended to use lime can be very good to remove the moisture at home. 1 kg of lime can absorb about 0.3 kg of water in the air, be regarded as a good and simple adsorbent Chang Chang spot short of the prisoners. Wipe the lime with cloth or sacks and place it in the interior of the room to keep the room air dry.

Send your message to us

WPC DIY decking Floor/wpc DIY flooring/wpc interlocking decking tiles

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords