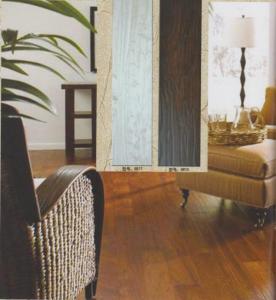

Cheap Price Birch Engineered Flooring

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500 m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Engieered Birch Flooring:

1) Rosewood Engineered Flooring

2) R/L*125*15 with 2mm veneer

3) 9 times UV anti-abrasion lacquer

4) T&G systerm

1. Wood Name: Rosewood Engineered Flooring

2. Species: Rosewood

3. Design: Traditional finishing

4. Construction: Engineered

5. Veneer: 2mm or as customer requested

6. Moisture content: 8%-10% or as per customer requested

7. Color: Brown or as per customer require

8. Grade: A/AB/BC

9. Width: 125-127mm

10. Length: Varying length 300-1200mm

11. Thickness: 12mm or 15mm

12. Joint4 side: T & G, with micro bevel

13. Installation Location: Below, on or above ground level

14. Installation: Glue or staple or floation

15. Lacquer: 9 layers treffert anti-scratch finishes

16. Gloss:Matt/semi-gloss/high-light

Good stability and high durablity, fine and clear texture.

- Q: The price is only 60 cents a sq foot but i heard there were a lot of advantages of engineer, it looks nicer becuase it goes together better, more moisture resisent etc. But i do i have a indoor door so i might have to refinish it more. Let me know from people who have it installed

- From my experience of installing all types of wood flooring, I definitely recommend solid wood flooring, basically because it is solid wood all of the way through which is great when it needs to be sanded and refinished. Engineered wood flooring looks good on the surface, however, this type of flooring has a really thin layer of wood veneer on top of a plywood base. If something heavy or sharp is dropped on this type of floor, it will damage the wood veneer floor which will expose the interior plywood base making an unattractive blemish which is very difficult to repair. Also engineered wood flooring cannot be sanded and refinished since this will go through the thin veneer on top.

- Q: The slab can vary in depth from -1inch to 0inch over a 10 foot range.we tried self leveling concrete. some parts of our initial pour,when we just learning did not turn out so well. now there are small areas that are as much as +.75inches.Can we shave/grind the high spots down. Do you recommend that we grind these spots down before installing the flooring?

- I do highly reccomend doing a job right. If you want a good job, either do a level set or rent a grinder and level the floor.

- Q: Composite flooring is divided into what kind of the best

- Generally is to strengthen the composite flooring and solid wood composite. Word of mouth the best composite floor, it must be the Yangtze floor. I decorated the floor when the floor on the selection of the Yangtze floor. At that time wanted to choose a reputation of the best composite floor, a friend recommended the Yangtze floor, he said the quality of the Yangtze floor is very good, waterproof performance is very good. I went to see and found the Yangtze floor of the flower of the boldness of the body of the powder but the pulp is very good, you can have a lot of choices, very user-friendly, and the Yangtze floor itself is particularly advanced moisture-proof technology, not only moisture is also environmentally friendly, There was no formaldehyde in the room after the floor was laid. Later, I chose the Yangtze floor, people still free installation, after-sales service to do is also in place. I gave me a few to decorate the friends have recommended the Yangtze floor. They now also think that the Yangtze floor is the best reputation of the composite floor. You go to the Yangtze floor of the store to see, their latest Maya retro series seems very good. Yangtze floor is a well-deserved reputation of the best composite floor

- Q: How long can a composite floor be used?

- How long can a composite floor be used?

- Q: What are the environmental standards for multilayer parquet and laminate flooring?

- What are the environmental standards for multilayer parquet and laminate flooring?

- Q: How to identify the quality of composite flooring?

- First, the color of paper, look at the surface of the color is naturally not really second, wear-resistant layer, to see the surface of the wear resistance, the state to achieve more than 4500 turn can be used in the family, the general manufacturers have reached more than 6000 rpm Third, the environmental protection level traces of Cao Ke 丨 long check Hsue magic, is the release of formaldehyde

- Q: Lacquered floor and composite floor how to distinguish

- Almost ~

- Q: Do not be too expensive, hope is inexpensive. More than 100 yuan the best. More

- Longxiang Fengxi floor can also be! The price is not expensive

- Q: What is the meaning of the composite floor suspension installation?

- Not directly pavement on the ground, but in advance on the ground laying wood keel, above the plate (woodworking board, multi-layer board or cheap fir flooring, etc.), composite flooring finally pavement in the grass-roots board. This method cost is high, but the effect is good, foot feeling more then pick up the waste dagger Zhazhao very close to solid wood flooring.

- Q: What is formaldehyde in the composite floor?

- Feeling asked silly The composite flooring is of course formaldehyde. Unleash the floor. Solid wood flooring also contains formaldehyde ah. Just how much different. Do not contain a floating fool first uncle Ying Jing scorpion nail halal only tiles and imported PVC flooring.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 24 Million |

| Main Markets | Europe; North America; |

| Company Certifications | ISO 9001:2008 ;IS01400:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% - 90% |

| No.of Employees in Trade Department | 700 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Cheap Price Birch Engineered Flooring

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500 m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords