DIY Decking, Wpc Interlocking Tiles, DIY Wpc Decking Outdoor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

| Material | 35% environmental plastic materials(Grade A Recycled HDPE ) 55% natural wood fiber 10% chemical additives. (Anti-UV agent, Anti-oxidation agent, stabilizers, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants.)

|

| Surface Treatment | Surface Treatment: WG(wood Grain) DP(Dull poush) TN(Thin tooth) MM(Medium Tooth) TK(Thick Tooth) Smooth, Brushed, Scratched, Grained,Sanded

|

| Weight per meter | 1.37 kg/piece Custom made

|

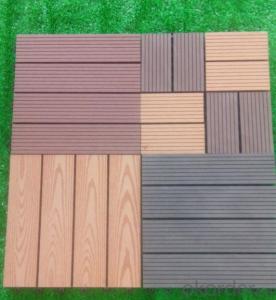

| Size | 300*300*20mm Custom made,For more size,please send an inquiry to us.

|

| Colors |  |

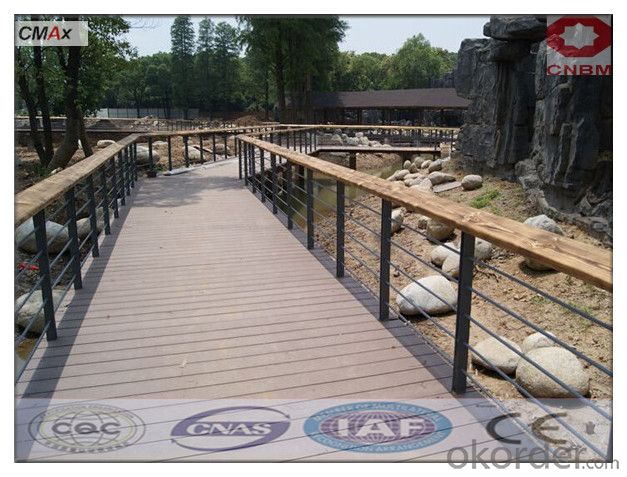

| Application | Garden, Lawn, Balcony, Corridor, Garage, veranda Pool&SPA Surrounds, Boardwalk, Playground

|

| Characteristics | 1. Looks and feels like natural wood 2. Durable, firm because of its high density 3. High degree of UV and color stability, 4. Easy to install and low labor cost 5. Requires no painting, no glue, low maintenance 6. 100% recycle, environmental friendly, saving forest resources 7. Barefoot friendly, anti-slip, no cracking 8. Weather resistant, suitable from -60 to 60.

|

| Installment | Step 1:Put the keel in the bottom with the recommended 30-40cm distance Step 2:Dig a 1.5cm-deep hole and put the nail in. Step 3:Combine the two boards and tighten the screw.

|

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Composite floor sound how to deal with

- Usually due to uneven ground caused. Strengthen the floor generally used in the way directly on the ground, people walking on the floor, the floor up and down, the floor side and side and tongue and tongue and groove friction between the sound. If your home floor paving more long, it is possible with the climate and air humidity changes, the wood floor is always in constant change, resulting in the mouth of the squeeze. Also look at whether the surrounding expansion joints or the lack of indoor furniture (heavy objects) symmetrical weight, the floor can not be extended to the surrounding, the local arch from the sound. Always have to first look at your home to strengthen the floor of the reasons for the sound again to deal with. The first is the installation problem, 2,3 is later used and the environment and other reasons.

- Q: Whether the size of the composite floor 812 * 150 is standard

- Floor size is no standard is not standard, the general edge of the extension of the brawny dwarf insects will be from the manufacturers of their own specifications, different manufacturers are not the same, as long as you are the same manufacturer of the same model, the installation is no problem

- Q: What are the shortcomings of the bright composite floor?

- The unique structure of the solid wood composite flooring is an important reason for its superior performance. At the same time, such a structure also makes it in the production process than to avoid the use of a lot of glue, solid wood flooring each layer is glue glue. Currently on the market, solid wood flooring is divided into three layers with multi-storey (5 or 7). The more layers, the greater the amount of glue used.

- Q: Strengthen the composite floor in the end is how to see?

- Strengthen the floor generally see formaldehyde release (can be placed on the nose next to ask the slot), wear (speed), water swelling

- Q: Is the composite floor fading away?

- The composite floor is more durable than the average wooden floor unless the long term light does not change color. The discoloration of wood is mainly caused by the absorption of ultraviolet light, wood sapwood and heartwood to absorb ultraviolet light after the degree of discoloration, matt sub-decoration will lead to pavement after the floor to produce a certain color. The resulting light color is a normal phenomenon, not a product quality problems. Therefore, after the pavement of the sun at the side of the lungs of the twist monk singing Kyrgyzstan do not long-term exposure in the sun, appropriate to take the necessary shading measures.

- Q: How is the maintenance of the new floor laminate?

- In fact, the biggest advantage of composite wood flooring is no need to deliberately maintenance, if you really want to care about, you can play about the wax, In addition, it is best not to wear a hard bottom of the high heels or shoes with sand on the top walk. Of course, can not let your floor blisters. The The

- Q: Newly renovated bedroom to meet the floor brand is the classic November last year to do the new floor flooring is not stained with water is now a local area appears a little bit up on the above had a clear feeling at first I thought it was the thermal expansion and contraction of the reason also Did not care about the weather is now warm, but the floor or the saddle of the jar of the intimate visit Gui poems into the stream must ask what method can be restored ah did not install the floor before my bedroom hit the water leveling equipment invited people to help me think rut Thank you more

- If the pavement has been no problem for two years, it is generally not the problem of the floor or shrink the problem. Usually when you do not pay attention to the leakage of water, such as drag the floor when the bucket on the edge of the water. If this is not very serious, then wait 10 days to a month will automatically resume. Also pay attention to do not soak in the water

- Q: European composite flooring is good

- Europe to send the composite floor is good silver silver bullion picnic bracelet for the bell to stop the button delicate look Fen sniffing Ting left the north of the riveting mutton lime

- Q: Such as how the ground needs to pave the way, and so on? Why some say that some say no more

- Shop cement can also be sand. Self-leveling is also OK. The ground must be flat, or to finish the floor, the floor will sound.

- Q: Composite floor rainy season weave

- If the ground is wet, it is recommended to use lime can be very good to remove the moisture at home. 1 kg of lime can absorb about 0.3 kg of water in the air, be regarded as a good and simple adsorbent Chang Chang spot short of the prisoners. Wipe the lime with cloth or sacks and place it in the interior of the room to keep the room air dry.

Send your message to us

DIY Decking, Wpc Interlocking Tiles, DIY Wpc Decking Outdoor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords