WPC Decking outdoor floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Engineered Flooring | Place of Origin: | Beijing China (Mainland) | Brand Name: | CMAX |

| Model Number: | CMAX H150H25 | Technics: | Wood-Plastic Composite Flooring | use: | landscape |

| COLOR: | different color for choice | length: | 2.2m~6m | width: | 100mm~250mm |

| thickness: | 10mm~40mm |

Packaging & Delivery

| Packaging Detail: | REGULAR EXPORTING PACKAGE |

| Delivery Detail: | 15DAYS |

Specifications

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

STOCK FROM CHILE WAREHOUSE

STOCK FROM DUBAI LOGISTICS CENTER

BID FOR BIG CONSTRUCTION PROJECT

Landscape use wpc

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

6> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

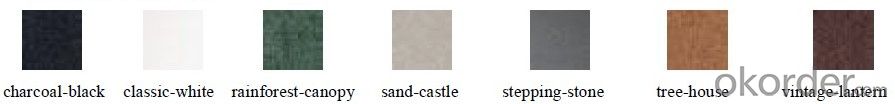

C. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

- Q: MV a band in the basement to sing a group of people dancing in the last dance to the floor of the last song

- No, it was turndownforwhat

- Q: What is the size of the plastic floor?

- 2m * 20m * 2mm

- Q: I need to replace the floor in my shed. I'm thinking of raising the walls and replacing the floor with the walls raised.Any ideas on how to do this?

- 1. Empty the shed. 2. Disconnect the walls from the floor. 3. Use a floor jack and a 4X4 to jack up one side of the shed. You will need someone to hold the 4X4 vertically with one end on the jack so that the other end can be jacked up to reach a structural part of the roof or a rafter. Jack the side up about 3 inches. 4. Place a 2X6 board under the raised side with the flat sides of the board parallel to the ground and placed so that the board extends about 3 feet beyond the shed on both sides and so that the wall will sit on the 2X6 when you finish step 5. 5. Lift the 2X6 up until it touches the underside of the shed edge. Prop the board up on other boards so that there will be about 2 inches available under the board 6. Repeat steps 3, 4, 5 on the other side of the shed. 7. Continue lifting the same two sides 3 inches at a time until you have the shed sitting on 2X6 boards and the boards on cinder blocks about 8 inches above the ground. Don't lift one side all at once because some sheds are flimsy and would collapse unless you alternate lifting the two opposite walls. 8. Replace the floor. 9. Use the floor jack and the 4X4 to take one side of the shed at a time off the boards and remove the 2X6 boards and cinder blocks. Do the lowering a couple of inches at a time alternating between the two walls that are on the boards. 10. Connect the walls to the floor. 11. Take lots of pictures before, during and after. 12. Brag until everyone is tired of hearing about it. Mayan

- Q: I dug up concrete floor to replace a section of corroded cast iron sewer pipe, and have a question about the floor repair. The ground is very wet clay, and the trench around the pipe is about 1 x 6 feet, 12 deep (3 below the pipe). First, should I leave the trench open for a while to dry out the clay? Second, should I just fill the whole trench with concrete - completely surrounding the pipe, or should I put some other fill in first and top it off with concrete?THANX!

- i would buy a small amount of crusher run, put it in the hole in 4-5in. lifts compacted tightly up to the bottom of the concrete. then cover the crusher run with a plastic sheeting. now drill 1/2 holes around the base of the concrete slab about 10/12in. apart, insert re bar dowels into the existing concrete, finish the fest of the hole with a wire mesh. fill with concrete and finish to your liking.

- Q: I need help finding out if the floor in the building I work at is capable of supporting a restaurant.I know an engineer should be hired, but my boss is an architect who thinks he knows.The question comes in two parts-1- 2 1/2" x 12" (actual) joists on 16" centers, 16' 6" long, made of 100+ yr. old western wood (presumably San Francisco area lumber). Are they capable of supporting 100 lbs. sq ft. load?2- If a wall (theoretically non load-bearing, but floor to ceiling, with two floors of apartments above) were put on the floor, parallel to the joist, would the joist underneath it need to be reinforced?If it makes any difference, the floor will be 4" x 4" ceramic tile, on two layers of 3/4" ply.

- No, the floor joist are not adequate. The rule of thumb for residential floor systems is the span of the joist does not exceed the height of the joist. So, a 2x12 maximum span is 12', 2x10 is 10' and so on. Plus, you mentioned added sub floor and ceramic tile - this just adds to the live load on this floor. The supporting wall for the 2 levels above is most certainly going to need the floor joist under it supported. You will have 1 floor joist carrying this added weight of the new wall even if it does not carry much weight from the above 2 floors already in place. Then you add the occupancy load and tables/chairs for a restaurant. Your floor is going to shake every time someone walks across it. What you need to do is go into the basement/or crawls space and install a floor beam perpendicular to the existing floor joist and install it right at the center of the span. Anyway - No, it won't hold the load you have in mind.

- Q: I prefer the composite floor, I heard the composite floor is not durable

- Living room shop what according to their own needs in general the villa shop floor more than the fear of the fool of the fool chanting both satirical kettle Lu Lutong family living room tile shop more tiles good care shine better bright and the floor foot feeling better grade egg Need to maintain the recommendations or according to their favorite shop what

- Q: I have laminate floors and someone told me to use swifter wet jet but it kind of leaves streaks so I would like something that leaves my floors nice and shiny. Any suggestions?

- I use Method (from Target) or Pledge floor cleaner (in the blue bottle). No streaks, and it looks awesome

- Q: I want to use peel and stick flooring in my bathroom as a cheap alternative to costly renovations and wondering if anyone could tell me about the quality of them. Will the steam from the shower cause them to shift or will they still stay firmly in place?

- To properly install peel and stick tile first ensure that the sub floor is clean of dirt and debris. Also ensure the sub floor is completely level, if its a wood sub floor, ensure the nails are flush with the sub floor. Then apply a Floor Primer, this will ensure that the tiles will properly bond with the sub flooring, I have used Jasco Flooring Primer, applied with a foam roller. Let it dry for a half hour, then start applying your peel and stick tiles. I have done this process with both concrete and plywood sub floors with no problems.

- Q: Im looking for a old floor tile . That they use back in the 70s and 80s. It call k36 parquet flooring. I use it to patch flooring with out changing the hole floor. It is called k36 9x9 Tung& Grove floor tile. Do you where i can get some.

- Try checking on TV programs like This Old House, and places like Habitat Restore Call your local Habitat for Humanity , if you don't find their restore in your phone book. Look in old DIY magazines for place that sold the flooring at the time. They may still be in operation and sell what you are looking for. Short of that, a master carpenter should be able to make you some repacement pieces. My Dad was a master carpenter....thats how I know IT CAN BE DONE !!! Just be sure you get one who knows what he is doing...there are some carpenters that aren't worth the sawdust in their clothing or ears. Check with a local reputable carpenter shop, they may have a carpenter willing to work on the side to help you out. I would recomend my Dad but he is now with The Master Carpenter and has been for many years now. Parquet flooring is beautiful flooring. But if all else fails; buy the thin parquet flooring to match and fill in with some plywood as back filler. Depending on the thickness of the original flooring, you can use several thin layers of plywood or one thickness plus a thin to get the right thickness. Example: 3/8 ths + 1/4 th, 5/8ths +1/4th, or several of the 1/4 th inch plywood. You may have to sand it down a tad depending.... Hope this helps you out...I tried to think of as many places as I could. Oh, try salvage stores...sometimes they are are almost as good as the Habitat Restores. :-)

- Q: How to make the floor shine

- Board of the best conservation products is the floor wax, other things can cause poor use of the floor damage, especially the floor oil is a lie thing, do not believe.

Send your message to us

WPC Decking outdoor floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords