Geogrids Que Son - PVC Coated Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

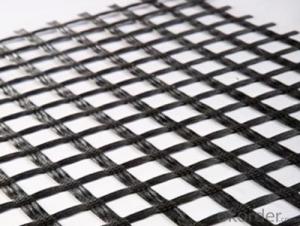

Structure of PVC Coated Polyester Geogrid Description:

PVC Coated Polyester Geogrd is Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal.

Main Features of PVC Coated Polyester Geogrid:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

PVC Coated Polyester Geogrid Images

PVC Coated Polyester Geogrid Specification:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are widely used in mining operations for reinforcement, stabilization, and erosion control in tailings storage facilities. They enhance the stability of the tailings by providing strength and preventing soil erosion, thereby improving overall tailings management.

- Q: Can geogrids be used in reinforcement of foundation soils?

- Yes, geogrids can be used in the reinforcement of foundation soils. Geogrids are commonly employed in civil engineering projects to enhance the stability and load-bearing capacity of soil. They are particularly useful in reinforcing weak or loose soils, preventing soil erosion, and minimizing settling or uneven settlement of structures. By providing tensile strength and distributing loads more evenly, geogrids help improve the performance and longevity of foundations.

- Q: What is the 110 type bidirectional geogrid?

- Geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching. It can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: How do geogrids improve the performance of bridge abutments?

- Geogrids improve the performance of bridge abutments by providing additional stability and reinforcement to the soil. They distribute the loads more evenly, prevent soil erosion, and increase the overall strength of the structure.

- Q: Geogrid grille read Shan or Zha?

- The traditional geogrid is mainly plastic grille and glass fiber grid, but because of the large deformation of plastic grille and glass fiber grille is mainly suitable for the reasons of the road engineering, and a new type of steel plastic composite geogrid.

- Q: Can geogrids be used in retaining wall facing systems?

- Yes, geogrids can be used in retaining wall facing systems. Geogrids are commonly used as reinforcement elements in retaining walls to enhance their stability and strength. They are placed within the soil layers behind the facing system to increase the resistance against lateral forces, reducing the potential for wall failure. By providing additional support, geogrids help to distribute the loads evenly and improve the overall performance of the retaining wall facing system.

- Q: Can geogrids be used in slope stabilization for mining waste dumps?

- Yes, geogrids can be used in slope stabilization for mining waste dumps. Geogrids offer effective reinforcement and stability to slopes by distributing the tension forces throughout the structure. They can help prevent slope failures, control erosion, and enhance the overall stability of mining waste dumps.

- Q: How do geogrids enhance the stability of landfill slopes?

- Geogrids enhance the stability of landfill slopes by providing reinforcement and increasing the strength of the soil. They are placed within the soil layers of the slope to distribute the applied loads and prevent excessive deformation. The geogrids act as a tension element, spreading the load across a wider area and reducing the risk of slope failure. Additionally, they improve the overall stability of the landfill slopes by controlling soil erosion, promoting drainage, and minimizing the potential for lateral movement.

- Q: Do geogrids enhance the stability of mechanically stabilized earth walls?

- Yes, geogrids enhance the stability of mechanically stabilized earth walls. Geogrids are commonly used in the construction of mechanically stabilized earth walls as they provide additional reinforcement and distribute the loads more efficiently. The geogrids act as tensile elements that resist lateral forces and prevent the soil from sliding or bulging, resulting in improved stability and overall performance of the earth walls.

- Q: Are geogrids resistant to moisture absorption?

- Yes, geogrids are generally resistant to moisture absorption. They are made from materials such as high-density polyethylene (HDPE) or polyester, which have inherent moisture resistance properties. This resistance to moisture absorption helps to maintain the stability and strength of geogrids in various construction and civil engineering applications.

Send your message to us

Geogrids Que Son - PVC Coated Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords