Pure Aluminum Coil - Wooden Pattern Roll Coated Aluminum Coil AA1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Pattern Roll Coated Aluminum Coil AA1100

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Wooden Pattern Roll Coated Aluminum Coil AA1100

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Pattern Roll Coated Aluminum Coil AA1100

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

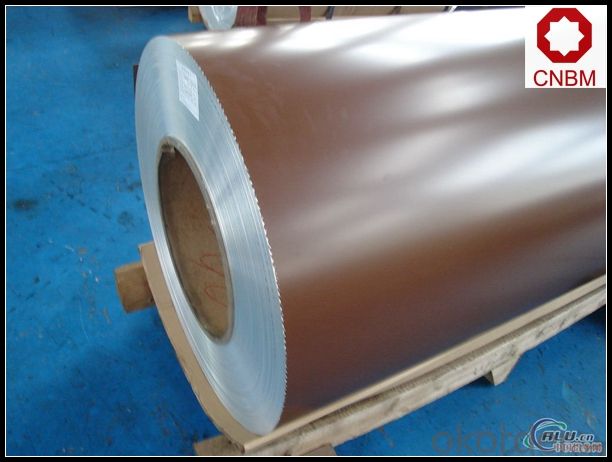

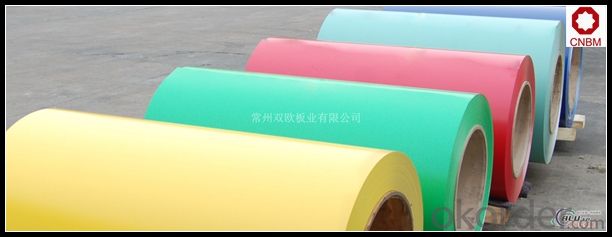

5. Image of Wooden Pattern Roll Coated Aluminum Coil AA1100

6. Package and shipping of Wooden Pattern Roll Coated Aluminum Coil AA1100

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum coils contribute to reduced material waste?

- Aluminum coils contribute to reduced material waste in several ways. Firstly, aluminum is a highly recyclable material, meaning that it can be melted down and reused multiple times without losing its properties. This recyclability factor alone contributes to reducing material waste as it prevents the need for new aluminum extraction and production. Additionally, aluminum coils are often used in industries where precision and efficiency are crucial, such as in the manufacturing of automobiles, HVAC systems, and electrical equipment. These coils can be easily customized to meet specific requirements, minimizing the need for excess material and reducing waste. Furthermore, aluminum coils offer high strength-to-weight ratio, meaning that they can be manufactured using less material while still maintaining the desired strength and durability. This lightweight characteristic contributes to reduced material waste as it allows for more efficient transportation and installation processes, resulting in lower fuel consumption and less environmental impact. Moreover, aluminum coils can be designed for longer lifespan and improved corrosion resistance. This durability factor helps to minimize the frequency of replacement, reducing material waste over time. Additionally, the long lifespan of aluminum coils makes them an attractive choice for sustainable construction practices, further contributing to reduced waste in the long run. Overall, the use of aluminum coils in various industries not only promotes recycling and reusability but also enables efficient customization, lightweight construction, enhanced durability, and extended lifespan. These factors collectively contribute to reducing material waste and making aluminum coils an environmentally-friendly choice.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

- Q: This question asks for methods to prevent rust formation on aluminum coils during indoor storage.

- <p>To prevent rust on aluminum coils when storing them indoors, ensure that the storage area is clean and dry. Keep the coils away from moisture and humidity, as these can cause oxidation. Use protective wrapping or coverings to shield the coils from dust and airborne moisture. Regularly inspect the coils for any signs of condensation or dampness and address these promptly. Maintain proper ventilation in the storage area to reduce humidity levels. Additionally, avoid stacking the coils directly on the ground; use pallets or racks to elevate them, which helps in air circulation and prevents contact with moisture that could be present on the floor.</p>

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Aluminum composite ceilings can indeed incorporate aluminum coils. The utilization of aluminum coils as the foundational material for manufacturing aluminum composite panels is quite common. These panels, in turn, serve as the foundation for constructing ceilings. The coils themselves typically consist of high-quality aluminum alloy and have undergone numerous processes to guarantee their durability, strength, and visual appeal. For added protection, the aluminum coils are coated with a layer of either PVDF or polyester. This coating serves to enhance their resistance to weathering, UV rays, and corrosion. Additionally, this protective layer allows for a wide array of color options, thus providing ample flexibility in design choices for aluminum composite ceilings. In summary, aluminum coils play a vital role in the production of aluminum composite ceilings. They offer a lightweight, fire-resistant, and long-lasting solution for a variety of architectural and interior design applications.

- Q: How to purchase PE polyester coated aluminum sheet and PVDF fluorocarbon coated aluminum coil?

- Both belong to color coated aluminum sheet and coil. Customers can purchase ordinary aluminum sheet or coil, and then go to special coating company to add PE polyester coating or PVDF fluorocarbon coating. The color is bright and quality is also very good. PE polyester coated aluminum and PVDF fluorocarbon coated aluminum coil has a wide range of usages: construction industry (aluminum-plastic panel, aluminum honeycomb, roof corrugated sheet, fireproof veneer, aluminum ceiling, shutter, rolling shutter door, garage door, awning, water gutter), electronic appliances (computer chassis, computer panel), lighting, furniture, solar reflector, air conditioning duct and the like. At present it is still applied in many areas including electronic appliance, instrument, lighting, packaging and house decoration.

- Q: How do I write ionic formula for Sodium Aluminum Silicate? Please explain in a easy way ,,,,,,,,,,,,

- www.okorder /

- Q: What are the different types of surface treatments for corrosion resistance?

- There are several different types of surface treatments that can be used to enhance corrosion resistance in various materials. These treatments can be categorized into mechanical, chemical, and electrochemical methods. 1. Mechanical surface treatments: These methods involve physically altering or modifying the surface of the material to improve corrosion resistance. Some common mechanical treatments include shot peening, sandblasting, and polishing. Shot peening involves bombarding the material with small metal pellets to induce compressive stresses, which helps to prevent corrosion. Sandblasting is a process of blasting the surface with abrasive particles to remove any existing corrosion and create a clean, smooth surface. Polishing involves the use of abrasives to create a smooth and reflective surface, which reduces the likelihood of corrosion initiation. 2. Chemical surface treatments: Chemical methods involve applying a chemical solution or coating to the material's surface to create a protective layer against corrosion. One commonly used chemical treatment is chromating, which involves the application of a chromate conversion coating. This coating provides a barrier against corrosion and also improves the adhesion of subsequent paint or coating layers. Another chemical treatment is anodizing, commonly used for aluminum surfaces. Anodizing creates a thick oxide layer on the surface, which enhances corrosion resistance and can also provide decorative finishes. Other chemical treatments include phosphating, passivation, and galvanizing, which involve the application of specific chemical solutions or coatings to protect against corrosion. 3. Electrochemical surface treatments: Electrochemical methods utilize the principles of electrochemistry to create a protective layer on the material's surface. One such method is electroplating, which involves the deposition of a thin layer of a more corrosion-resistant material onto the surface of the base material. This can be done using various metals, such as zinc, nickel, or chromium. Another electrochemical treatment is anodic protection, where a sacrificial anode is connected to the material, causing the anode to corrode instead of the material. This process is commonly used for pipelines and underground structures. Overall, the choice of surface treatment for corrosion resistance depends on the material, the intended application, and the desired level of protection. Each treatment method has its advantages and limitations, and it is important to consider factors such as cost, environmental impact, and performance requirements when selecting the appropriate treatment.

- Q: Are aluminum coils suitable for low-maintenance applications?

- Indeed, low-maintenance applications are well-suited for the use of aluminum coils. Renowned for its strength and ability to resist corrosion, aluminum proves to be an exceptional selection for applications that demand minimal upkeep. Unlike alternative materials like steel, aluminum coils remain free from rust and do not necessitate regular painting to preserve their aesthetic appeal. Furthermore, the lightweight nature of aluminum facilitates effortless installation and handling, particularly in low-maintenance scenarios where frequent maintenance may prove impractical or undesirable. Ultimately, aluminum coils serve as a dependable and low-maintenance solution for a range of applications.

- Q: Are aluminum coils suitable for roofing?

- Yes, aluminum coils are suitable for roofing. Aluminum is a lightweight and durable material that is resistant to corrosion, making it an excellent choice for roofing applications. It is also highly reflective, which can help to reduce energy costs by keeping the building cooler. Additionally, aluminum coils are easy to install and maintain, making them a popular option for both residential and commercial roofing projects.

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Yes, aluminum coils can be used in the production of fire-resistant structures. Aluminum has a high melting point and excellent thermal conductivity, making it suitable for applications where fire resistance is required. Additionally, aluminum does not burn and can help to prevent the spread of fire, making it a popular choice for fire-resistant structures such as fire doors, fire-resistant walls, and fireproof insulation.

Send your message to us

Pure Aluminum Coil - Wooden Pattern Roll Coated Aluminum Coil AA1100

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords