Aluminum Coil Anodizing Corporation Aca - Hot Sale AA1100 Aluminum Coil/Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

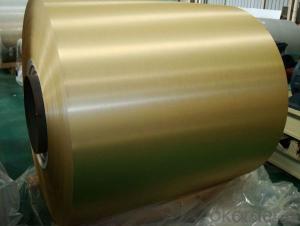

1.Structure of Alumunum Coil/Roll in Hot Sale AA1100:

Alumunum Coil/Roll in Hot Sale AA1100is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Alumunum Coil/Roll in Hot Sale AA1100 is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of Alumunum Coil/Roll in Hot Sale AA1100:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Alumunum Coil/Roll

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

4. Production of Alumunum Coil/Roll in Hot Sale AA1100

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- Pete is on the right track, but I think that rather than primer, what you need is to wash the aluminum with acid after you use a chemical stripper to get the paint off. The acid dissolves the layer of corrosion that all aluminum gets with exposure to air and also gives the fresh primer something to adhere to. You can lightly sand aluminum by hand or with a random orbit sander, but aluminum dust has been linked to alzheimer's disease so wear a good mask. But if your canoe has a lot of paint still on it or a lot of rivets and seams, then a stripper made for aluminum will save you a lot of time and effort. Go to a place that specializes in paints and finishes specific to the boating, recreational vehicle, or trucking industries as they deal with aluminum all the time and have the specialized products that you need in order to refinish and repaint it because it isn't like steel or wood and requires specific formulations. If you try to skip a step or buy the wrong stuff, your efforts will probably not succeed because working with aluminum is unlike any other material. Read and follow all directions and safety instructions carefully because the chemicals involved are strong and can give off toxic fumes. Because most things made from aluminum are subject to a wide variety of climates and rough handling, you need to buy products that are specially formulated for it and follow the steps and safety precautions exactly or all your hard work will probably be for naught.

- Q: Can aluminum coils be used for architectural applications?

- Yes, aluminum coils can be used for architectural applications. Aluminum is a versatile and lightweight material that offers excellent corrosion resistance, making it suitable for various architectural purposes. Aluminum coils can be used for exterior cladding, roofing, facades, and even interior applications like ceilings and wall panels. The coils can be easily formed, cut, and shaped, allowing for flexibility in design and creative architectural solutions. Additionally, aluminum coils can be coated with various finishes, such as paint or anodized coatings, to provide enhanced aesthetics and durability. Overall, aluminum coils are a popular choice in the architectural industry due to their versatility, durability, and aesthetic appeal.

- Q: This question asks for a comparison between steel wires and other materials when used in coilings, highlighting the pros and cons of steel wires.

- <p>The advantages of using steel wires for coilings include high tensile strength, durability, and resistance to corrosion. Steel wires are also cost-effective and widely available. They offer excellent fatigue resistance, making them suitable for applications requiring repeated coiling and uncoiling. Disadvantages include higher weight compared to some alternatives, which can be a concern in certain applications. Steel wires can also be prone to rust if not properly treated, and they may not be as flexible as some other materials, potentially leading to difficulties in handling or installation. Additionally, steel's magnetic properties can be a disadvantage in environments where non-magnetic materials are required.</p>

- Q: I know it's almost 100% aluminum, but not completely. Does it have any impurities? I need to find the molar mass of aluminum foil.

- just use aluminum and goto the periodic table of elements. its all aluminum. they used to make it of tin.

- Q: Is it possible to determine the spring constant of an aluminum coil using a spring compressor?

- <p>Yes, you can use a spring compressor to measure the spring constant of an aluminum coil. The spring constant (k) can be calculated using Hooke's Law, which states that the force exerted by a spring is proportional to its displacement (F = kx). By applying a known force to the spring and measuring the resulting displacement, you can calculate the spring constant. A spring compressor can apply a controlled force, and a displacement gauge can measure the compression, allowing you to determine the spring constant accurately.</p>

- Q: What is the typical elongation of aluminum coils?

- The typical elongation of aluminum coils can vary depending on several factors, such as the specific alloy and temper of the aluminum, the manufacturing process, and the intended application. However, aluminum coils generally exhibit a high elongation capability. On average, aluminum coils can have an elongation of around 5-15%, which means they can stretch or deform by this percentage without fracturing or breaking. This property is a result of the inherent ductility of aluminum, which allows it to be easily formed and shaped without losing its structural integrity. The elongation of aluminum coils plays a significant role in various industries, such as construction, automotive, and aerospace, where the material is commonly used. It allows for efficient fabrication processes, such as bending, rolling, and stamping, to create complex and precise shapes. It is important to note that the elongation of aluminum coils can be further improved through specific alloying elements and heat treatments. These processes can enhance the material's properties, making it even more suitable for demanding applications that require superior strength, ductility, and elongation capabilities. In conclusion, while the typical elongation of aluminum coils ranges from 5-15%, it is crucial to consider the specific alloy, temper, and manufacturing processes to accurately determine the elongation properties for a particular application.

- Q: How do aluminum coils contribute to sustainable building practices?

- Aluminum coils contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, meaning that the production and use of aluminum coils have a minimal impact on the environment. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, reducing greenhouse gas emissions and conserving natural resources. Additionally, aluminum coils are lightweight and durable, making them an ideal choice for sustainable building practices. The lightweight nature of aluminum reduces the load on the building structure, leading to lower transportation costs and energy consumption during construction. Its durability ensures that aluminum coils have a long lifespan, reducing the need for frequent replacements and associated waste generation. Furthermore, aluminum is resistant to corrosion and requires minimal maintenance. This quality contributes to the longevity of buildings, reducing the need for repairs and replacements over time. This not only saves resources but also reduces the overall environmental impact of the building. Moreover, aluminum coils offer excellent thermal conductivity, which can contribute to energy efficiency in buildings. When used as part of insulation systems or in HVAC systems, aluminum coils help to regulate temperature and minimize energy consumption. This can result in reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils can be used in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for creative and innovative design solutions, promoting sustainable building practices by incorporating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By choosing aluminum coils for construction, we can minimize the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately leading to a more sustainable built environment.

- Q: The user is asking if it's possible to use an electric welder for joining aluminum coils.

- <p>Yes, you can use an electric welder to weld aluminum coils together. However, it's important to use the correct type of welder and settings. Gas tungsten arc welding (GTAW), also known as TIG welding, is commonly used for aluminum due to its precision and ability to control heat input. MIG (Metal Inert Gas) welding can also be used for thicker aluminum materials. Ensure you use the right filler material, a suitable welding current, and proper shielding gas to prevent oxidation. Always follow safety precautions and consult with a professional if you're unsure about the welding process.</p>

- Q: Roll presented above 1 complete circles are brineling put on work roll after the new rolling, less than 12 volumes in the aluminum surface will be presented in the corresponding position of a straight roller, a roller indentation in the above, check the work roll above a pit. Replace the upper support roll for only a few days. Want to know what's going on?Should not be bearing problems, because the bearings have been used for almost 4 years, it should not be bearing problems, and now they are suspected of bending cylinder seal problems, oil seepage phenomenon.

- For a few days and roll crushed?Whether or not the work roll tilt and the positive and negative camber of the roll are controlled, the work roll is running abnormally, and the backup roller is rubbed.

- Q: Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can be used for automotive body panels. In fact, aluminum is a popular choice for car manufacturers due to its lightweight and corrosion-resistant properties, leading to improved fuel efficiency and longevity of the vehicle.

Send your message to us

Aluminum Coil Anodizing Corporation Aca - Hot Sale AA1100 Aluminum Coil/Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords