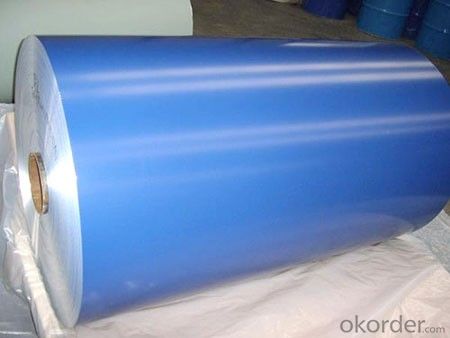

Coated Aluminum Pipes Coil-AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.General Information of Color Coated Aluminium Coil with Competitive Prices

Aluminum coil is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

Alloy | AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-4.0mm |

Width: | 10mm- 2000mm |

Coating | PE(Polyester) |

Painting Thickness | Standard 16-25 microns, max 40 microns |

Color | Acording to Ral colors or customer’s samples |

Standard: | GB/T17748-1999, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

2 Usage/Applications of PE Coated Aluminum Coil/Sheet

Our company's PE Coated Aluminum Coil/Sheet have been widely used in the fields of construction and decoration(garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipe, sanwich panels and drainage, etc.

- Q: Are aluminum pipes easy to install?

- Indeed, the installation of aluminum pipes is typically uncomplicated. Their lightweight nature facilitates effortless handling and maneuverability, distinguishing them from alternative substances. Moreover, aluminum pipes possess a sleek exterior, thereby permitting simple insertion and connection. Furthermore, aluminum pipes can be readily customized and sculpted to meet precise specifications, thereby enhancing the adaptability of the installation procedure. Nevertheless, it is crucial to emphasize the employment of appropriate tools and methodologies to guarantee a sturdy and impervious installation.

- Q: Can aluminum pipes be welded?

- Yes, aluminum pipes can be welded. Aluminum is a highly weldable material and can be easily joined together using various welding processes such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and even oxy-acetylene welding. However, it is important to note that welding aluminum requires specific techniques and considerations due to its unique properties. For instance, aluminum has a higher thermal conductivity and lower melting point compared to other metals, so it requires more heat control during the welding process. Additionally, aluminum forms an oxide layer when exposed to air, which can hinder the welding process. Therefore, proper cleaning and preparation of the aluminum surface is crucial before welding to ensure a strong and sound weld joint.

- Q: How do aluminum pipes compare to titanium pipes in terms of weight?

- Aluminum pipes are generally lighter than titanium pipes. Aluminum has a lower density compared to titanium, which means that for the same volume, aluminum pipes will weigh less than titanium pipes. This characteristic makes aluminum pipes more suitable for applications where weight reduction is a priority, such as in aerospace or automotive industries. However, it's important to note that titanium pipes offer superior strength and durability, making them ideal for applications that require high resistance to corrosion, extreme temperatures, or heavy loads. Ultimately, the choice between aluminum and titanium pipes depends on the specific requirements of the intended application.

- Q: What is the maximum operating temperature for aluminum pipes?

- The maximum operating temperature for aluminum pipes can vary depending on the specific alloy used, but generally, it ranges from 300 to 400 degrees Fahrenheit (150 to 200 degrees Celsius).

- Q: The aluminum pipe joint on the unit is broken. Take a look at it. There is a copper ring on the aluminum tube. I don't know how it was pressed. Do you know any friend here? What equipment do you need to press up? Do you have any manual equipment? A friend who knows is better illustrated with a picture. Thank youThank you friends reply, but you're wrong, the copper ring is pressed up and see what this is the copper ring on both sides of the copper ring is a device pressure to take off the copper ring in the aluminum tube plays the role of sealing

- This is not what equipment press up, that is, the nut screwed up,The card sleeve is straight through, a set is a pair of silk, a copper ring, a nut

- Q: What are the different coating options for aluminum pipes?

- Depending on the specific application and requirements, there are various coating options available for aluminum pipes. Some of the most commonly used coatings for aluminum pipes are: 1. Anodizing: Anodizing is a popular method for coating aluminum pipes because it enhances corrosion resistance and durability. It involves creating an oxide layer on the aluminum surface, which can be colored or dyed for aesthetic purposes. 2. Powder coating: Powder coating is a dry finishing process in which an electrostatically applied powder forms a hard and durable coating on the aluminum pipe surface. It offers excellent corrosion resistance and can be customized with different colors and textures. 3. Epoxy coating: Aluminum pipes exposed to harsh environments or chemicals often benefit from epoxy coatings. These coatings provide excellent chemical resistance, strong adhesion, and protection against corrosion. They are typically applied through spray or dip processes. 4. Polyethylene coating: Polyethylene coatings, commonly known as PE coatings, are commonly used for aluminum pipes that will be buried underground or used in corrosive environments. They create a protective barrier against corrosion and abrasion, ensuring the long-lasting performance of the pipe. 5. Thermal spray coatings: Thermal spray coatings involve applying a layer of metal or ceramic material onto the aluminum pipe surface using a high-temperature process. These coatings offer enhanced wear resistance, thermal insulation, and corrosion protection. 6. Ceramic coatings: Ceramic coatings are ideal for aluminum pipes exposed to high temperatures. They provide excellent heat resistance, thermal insulation, protection against oxidation, and can enhance overall performance in extreme conditions. It is important to consider factors such as the intended use, environmental conditions, aesthetics, and budget when selecting a coating option for aluminum pipes. Seeking guidance from coating experts or professionals can assist in determining the most suitable option for a specific application.

- Q: Are aluminum pipes suitable for vacuum systems?

- Yes, aluminum pipes can be suitable for vacuum systems depending on the specific requirements and conditions of the system. Aluminum is a lightweight and corrosion-resistant material, making it a popular choice for various applications, including vacuum systems. However, it is important to consider factors such as the level of vacuum required, the temperature range, and the potential for outgassing. In certain cases, aluminum may not be the best choice, especially for high vacuum applications or systems that require extremely low levels of outgassing. In such cases, materials like stainless steel or titanium may be more suitable. It is crucial to consult with experts or engineers who specialize in vacuum systems to determine the most appropriate material for a specific vacuum system.

- Q: How can the plastic parts be fastened in the aluminum tube and the plastic parts are not drawn out?

- This habit is not defined, as engineers, all digital, not with the concept of size, good or bad, precision, and other description of engineering and technical problems.

- Q: Are aluminum pipes suitable for architectural purposes?

- Yes, aluminum pipes are suitable for architectural purposes. They are lightweight, durable, and corrosion-resistant, making them ideal for various architectural applications such as building facades, handrails, and structural components. Additionally, aluminum pipes offer flexibility in design due to their versatility in shape and size, allowing architects to create unique and aesthetically pleasing structures.

- Q: I have used ab repair several times, each time with only three months and leakage of fluorine, hope you master generous with your criticism,

- There is a very simple method for aluminum weldingWith a good adhesive (polyurethane two parts glue) plus aluminum foil multilayer adhesive methodHope to help you.

Send your message to us

Coated Aluminum Pipes Coil-AA1100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches