Wood Plastic Composite WPC Factory for Door Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

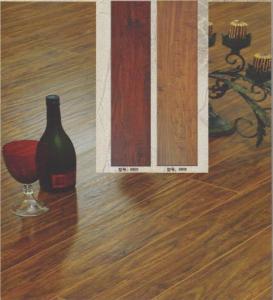

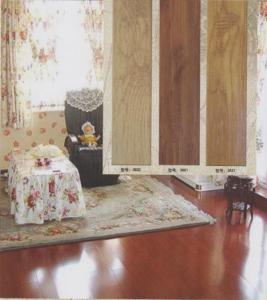

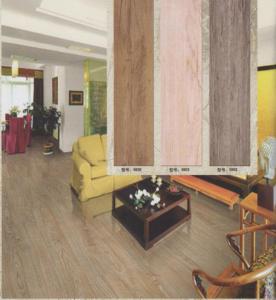

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

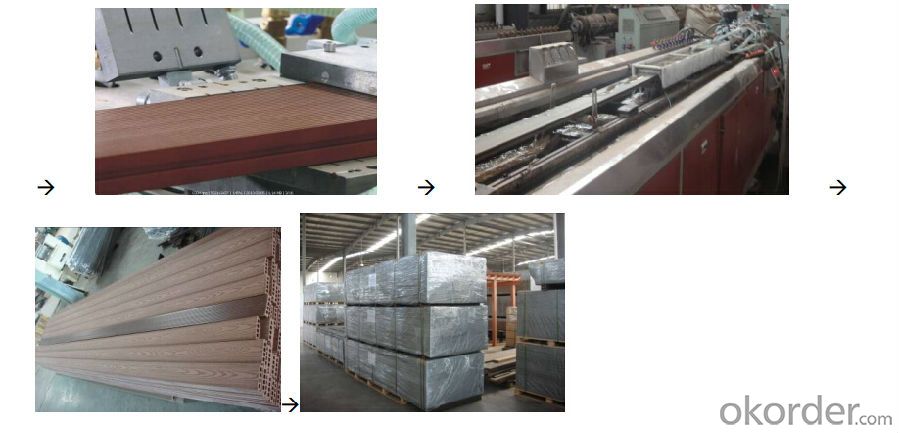

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

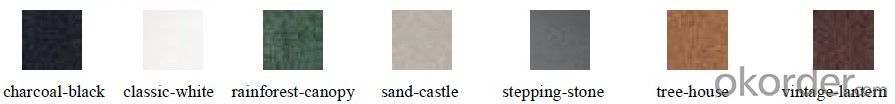

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

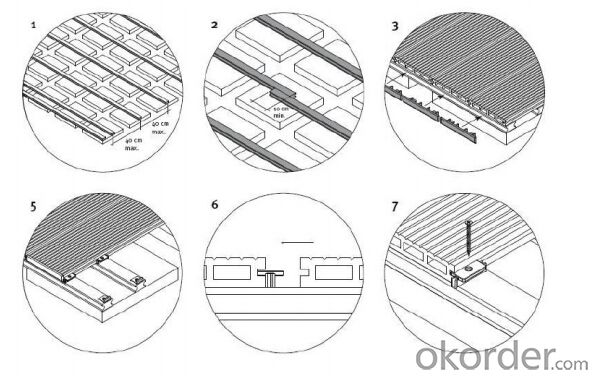

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q: Im trying to buy a house but it needs a new bathroom room. Im a tight budget with the down payment and everything. Does anyone know cheap bathroom floor ideas?

- Linoleum, come in every style imaginable.

- Q: I have laminate flooring my in my bathroom. The seem appears to have warped, How do I seal the seem once again? It is a wooden style flooring (but not the snap together type)

- Laminate floors are not actually wood. Engineered floors have a thin layer of wood on top. Hardwood floors are all wood. Laminate floors are only a picture of wood on top of a substrate. That substrate is usually something called MDF. MDF will swell when it gets wet. This is likely your problem. There is no repair except for replacing those sections. Tongue and groove laminate is glued together making this almost impossible. If you had hardwood floors they could be sanded and refinished. If you have engineered floors they might, or might not be able to be refinished, depending on the thickness of the veneer on top. Sorry for the bad news.

- Q: Flooring this piece of general to buy what need to pay attention to what the general kick line to send it? ,

- The floor is generally not sent to the baseball of these are to spend money! The floor generally see the wear resistance of pressure penetration

- Q: is there any chemical/solution to remove acid stains from floors?please help me.

- Flooring is one of the important aspect which add beauty to your home/building. Marble makes a luxurious material for floors, walls, countertops and mantels. This porous material tends to absorb stains from liquids and oils that have come in contact with it. Certain liquids, such as juice or wine, may contain certain acids that, once absorbed, leave an unsightly and harmful stain in the marble. Applying a poultice treatment will pull the stain back out of the pores of the marble and remove the stain. This low-maintenance treatment will restore your marble surface to its original shine. Good Luck...

- Q: How to calculate all the floor area and the floor area to be laid

- CO off the last number can be out

- Q: i live on th second floor of my house....and my room wen ever i step in some spots the floor creks or makes a weird bouncy noise...i have ood floor....i dont want no cuttin involved...how do i fix this do i nail more nails in?

- I worked with a flooring company and the guy would put talcum powder between the cracks to stop them from squeaking, any fine powder works, but talcum powder is really fine apparently and gets in farthest.

- Q: My new house has blonde floating floors and I have no idea how to maintain them. My family doesn't eat or drink outside of the kitchen and we typically take off our shoes at the door. I have a shorthaired little dog who isn't going to be very happy when I try to put doggy house slippers on him because I'm so worried about scratching the floor. I'm OCD; it'd drive me crazy! I ll be using protectors under all furniture.What type of cleaner would one use weekly or biweekly for thorough cleaning on this kind of floor?Is it ok to use a Swiffer spray? I detest vinegar. Can I cover the Swiffer with a dryer sheet or will that coat the floor?Thanks

- How To Clean Floating Floors

- Q: I installed a floating floor and it seems that water can penetrate between the seems. how could I seal these?

- Buff the floor with a floor buffer that has a white pad and a 220 grit sanding screen on the bottom. Then seal the floor with a sanding sealer, then follow that up with a coating of floor finish. I suggest Bona traffic floor finish.

- Q: If you sit on a couch and crawl "down" from it, do you crawl on the floor or to the floor? Or something else entirely?

- You're crawling TO the floor because you were originally on the couch. But if you're already on the floor you're crawling ON the floor :)

- Q: 15 square meters of the room shop the general wooden floor to how much money?

- Hello general wood floor at least package to install 60 yuan 15 square is 900 yuan plus 1000 yuan accessories! Google expert [He Guangning] to answer your questions. If my answer is helpful to you, please take it in time! Your approval is the biggest motivation for my answer! Thank you!

Send your message to us

Wood Plastic Composite WPC Factory for Door Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches