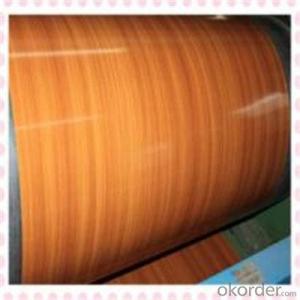

PPGI Cold Rolled Hot Dipped Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

BASE SUBSTRATE | Hot dip galvanized steel (HDGI), ZINCALUME STEEL COIL |

GRADE | SGCC,ENG10142, DX51D, ASTM A653 |

ZINC COATING | 30-200g |

COIL WEIGHT | 3-7TON |

INTERNAL DIAMETER(ID) | 508mm |

THICKNESS | 0.2-0.8 mm |

WIDTH | 914-1250mm |

FINISHING | SMOOTH OR MATTE |

PATTERN | MARBLE GRAIN OR WOOD GRAIN |

PAINT | EXPOXY, POLYESTER, PVDF |

TOP LACQURE COATING | >20 um |

BACK LACQURE COATING | 7 um |

CAPABILITY | 100000 TON per year |

QUALITY QURANTEE | 10 YEARS OF OUTDOOR USING FOR PE |

Applications of Prepainted Galvanized Steel Coil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Coating Chief Feature

| Project | Pencil hardness | Reverse impact | T bending | Cupping test | MEK cleaning |

| Front/back | ≥ H/2H | ≥ 9J/6J | ≤ 3T/5T | ≥ 6mm/4mm | ≥ 100time/50time |

Structure of GI/PPGI

| Item | Thickness | Type | Feature |

| Laminated film | 50μm | Polyethylene | Protecting from scratchs and contamination (option) |

| Top coat | 20μm | Polyester Fluorine | Chemical resistance and formability |

Primer coat | 5μm | Polyester | Workability, corrosion resistance and adhesion to the primer coating |

| Chemical treatment | 1μm | Chromate | Good adhesion and corrosion resistance |

| Substrate | 0.2mm-1.2mm | GI.GL,AL | GI.GL,AL |

| Back coat |

5±2μm |

Epoxy | Corrosion resistance and adhesion to the substrate |

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the challenges in coil recoiling?

- Some of the challenges in coil recoiling include achieving precise and consistent coiling, minimizing coil distortion and tangling, preventing material damage or breakage during recoiling, and ensuring efficient and safe handling of coiled materials. Additionally, factors such as coil size, weight, and material properties can also pose challenges in the recoiling process.

- Q: i was giving this old knive. the knife part is stainless steel and has a couple rust spots but im not sure that the handle is (i think stainless) but it has this un smooth surface i dont think its rust because its not brown. would rubbing alcohol help clean it?

- no if it was stainless it would have not rusted, we use lemon juice and a brillo pad

- Q: What are the different types of steel coil storage systems used during processing?

- There are several types of steel coil storage systems used during processing, including coil racks, coil cradles, coil saddles, coil cars, coil turnstiles, and coil transfer cars.

- Q: How are steel coils used in the manufacturing of construction excavators?

- Steel coils are used in the manufacturing of construction excavators as they are often the primary material for constructing the structural components of the excavator. These coils are typically processed and shaped into various parts, such as the chassis, boom, arm, and bucket, providing the necessary strength and durability required for heavy-duty construction work.

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency using a variety of methods to ensure that the final product meets the desired specifications. One common method is visual inspection, where trained inspectors examine the steel coils under controlled lighting conditions to detect any variations in color. This is done by comparing the color of each coil to a standard color chart or a previously approved sample. Any discrepancies are noted and further analysis is conducted. Additionally, advanced technologies such as spectrophotometers may be employed to measure the color of the steel coils objectively. Spectrophotometers use light to measure the reflective properties of the steel surface, allowing precise color analysis. The obtained color data is then compared to the specified color range, and any deviations are flagged for further investigation. Furthermore, some manufacturers may use automated color measurement systems, such as colorimeters or color cameras, to inspect steel coils for color consistency. These systems can quickly and accurately assess the color of each coil, ensuring uniformity across the entire batch. Overall, the inspection of steel coils for color consistency involves a combination of visual inspection, spectrophotometry, and automated color measurement systems. This comprehensive approach helps to guarantee that the steel coils meet the required color standards, providing consistent and high-quality products to customers.

- Q: What is the maximum diameter of a steel coil?

- The maximum diameter of a steel coil can vary depending on the specific manufacturing process and equipment used. However, in general, the maximum diameter of a steel coil can range from a few inches to several feet.

- Q: What are the different coil edge options?

- The different coil edge options include open coil, continuous coil, offset coil, and pocket coil.

- Q: i like stainless steel guns, especially the SW 686 .357, i plan on getting one but my question is would polishing the stainless steel make the gun more prone to corrosion over leaving it as it is? and will the polished surface appear uneven after use and sitting? obviously all metal takes some sort of upkeep but is polished more high maintenance than non-polished?

- Stainless Steel Revolver

- Q: I have a mountain bike w/ 26 wheels. My question is what's the biggest difference between aluminum vs. steel? If most of my riding is off-road, wouldn't the steel wheels be stronger/more durable?

- Aluminum is by far the better choice for wheels, mirageguitarwork is right on the money with his description. One other thing that detracts from steel wheels is that they rust. Wheel builders used to chrome plate them, but all this did was add weight. The wheels would eventually still rust, and this weakens them even more.

Send your message to us

PPGI Cold Rolled Hot Dipped Galvanized Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords