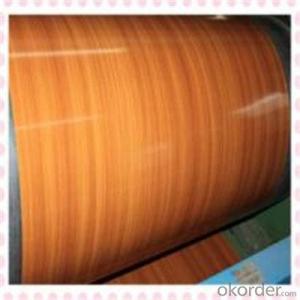

Wood Finish Pattern Printed Galvanized PPGI Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 120004444 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of PPGI:

Grade : SGCD,SGCH, Q195,DX51D

Galvanized steel sheet /coil features:

1. Zinc coating :40-180g( as required)

2. thickness:0.2-1.2mm

3. width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

4. coil id:508mm/610mm

5. coil weight: 4-10 MT(as required)

6. surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors, booths, shutters, watch rooms, makeshift houses, street waiting room (booth), refrigerators, etc. |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens, ceilings, toilets, interior elevator lobby, stairwayventilating duct, communication pipelines. |

Specifications of PPGI:

Aplication | Building exterior application |

Building interior application | |

Furniture | |

Household appliances | |

Steel windows | |

Others |

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: How are steel coils used in the production of metal roofing?

- Steel coils are used in the production of metal roofing by being fed through a series of machines that shape, cut, and coat the steel to create the final roofing product. The coils are uncoiled and flattened, then formed into the desired profile using roll forming machines. The formed sheets are then cut into specific lengths and coated with protective layers to enhance durability and corrosion resistance. These coated steel sheets are then packaged and shipped to construction sites for installation as metal roofing.

- Q: What is stainless steel 316, and what are its properties and uses?

- 316 is the second most common grade (after 304); for food and surgical stainless steel uses; alloy addition of molybdenum prevents specific forms of corrosion. It is also known as marine grade stainless steel due to its increased resistance to chloride corrosion compared to type 304. 316 is often used for building nuclear reprocessing plants. 316L is an extra low carbon grade of 316, generally used in stainless steel watches and marine applications, as well exclusively in the fabrication of reactor pressure vessels for boiling water reactors, due to its high resistance to corrosion. 316Ti includes titanium for heat resistance, therefore it is used in flexible chimney liners.

- Q: How does adding carbon to Iron make it stronger? How does steel look the molecular structure in comparison to Iron? looking for a very scientific answer =]

- Cast Iron' is typically brittle, while 'Maleable Iron' has a small percentage of carbon which allows it to be hammered and formed. Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron. Steel is a crystalline structure of iron molecules interspersed with carbon molecules. This is properly known as cementite. The hardness and malleability of steel depends not only on the carbon content, but on how the carbon and iron molecules are arranged to one another. Internal stresses in the steel's crystalline structure will increase or decrease depending on the temperature it is subjected to and the rate at which molten steel is cooled. This 'tempering' can increase the strength of the steel at the expense of brittleness.

- Q: is a 1962 steel penny worth anything?

- 1962 D Penny

- Q: What are the main characteristics of steel coils?

- The main characteristics of steel coils include their high strength and durability, excellent corrosion resistance, and ability to be easily formed and shaped. They are typically made from carbon steel and come in various widths, thicknesses, and lengths. Steel coils are commonly used in a wide range of industries such as construction, automotive, and manufacturing for applications such as roofing, structural components, and electrical appliances.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils significantly affects their performance. A smooth and even surface finish enhances the coil's ability to resist corrosion, improves paint adhesion, and enhances the overall appearance of the final product. Additionally, a properly finished surface reduces friction, facilitating better processing and handling during manufacturing. Therefore, the surface finish of steel coils plays a crucial role in determining their durability, functionality, and aesthetic appeal.

- Q: How are steel coils used in the agricultural industry?

- Steel coils are commonly used in the agricultural industry for various purposes. They are primarily used in the manufacturing of machinery and equipment such as tractors, harvesters, and irrigation systems. Steel coils are also used in the construction of storage structures, fencing, and other infrastructure required for agricultural operations. Additionally, steel coils are utilized in the production of farm implements like plows, cultivators, and seeders, providing durability and strength to withstand the demanding field conditions.

- Q: How are steel coils used in the appliance industry?

- Steel coils are used in the appliance industry to manufacture various components such as outer panels, frames, and internal structures of appliances like refrigerators, washing machines, and ovens. The coils are processed to create specific shapes and sizes, providing strength, durability, and stability to the appliances.

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they are rolled into structural shapes, such as beams and columns, that provide the necessary strength and support for the bridge. These coils are then fabricated, welded, and assembled to create the various components of the bridge, ensuring it can withstand heavy loads and withstand the test of time.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

Send your message to us

Wood Finish Pattern Printed Galvanized PPGI Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 120004444 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords