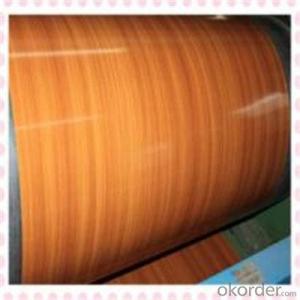

hot rolled PPGI printed steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of prepainted galvanized steel coil

Base Material | (1)Galvanized steel; |

Grade | SGCC, DX5ID, ASTM, EN10142, S350GD, etc |

Thickness | 0.18~1.00mm |

Width | ≤1250mm |

Zinc Coating | 50~200g/m2 |

Pattern | Wood grain, Marble, Brick, granite and Camouflage series, etc |

Paint | PE , PVDF , SMP , HDP |

Coil ID | ø508mm |

Coil Weight | ≤6T |

Application of wooden prepainted galvanized steel coil

Widely used in construction, household appliance, furniture, transportation and other industry

Width | 600mm-1250mm |

Color | Grey white, sea blue, red or any RAL standard |

Standard | ASTM, AISI, DIN, GB,JIS |

Material | SGCC,SGCD,SECC,SECD,DX51D+Z, S350GD, S450GD, S550GD |

Technique | Cold rolled, hot-dipped galvanizing, color coated, galvanized, Galvalume |

Surface Structure | Galvanized, Galvalume, zero spangle, regular spangle or normal spangle |

Surface treatment | Chromate and oiled, chromate and non-oiled |

Min order | 25 tons |

Applications:

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorframe, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: Does steel contain nickel?

- Stainless steel is a steel than contains at least 10% chromium. But there are many nuance of stainless steel, with different composition for various applications, and some do contain nickel. But not all types of stainless steel contain nickel.

- Q: How do steel coils contribute to the marine vessel construction industry?

- Steel coils are a vital component in the marine vessel construction industry as they serve as the primary material for building the hulls and structural components of ships and boats. The high strength and durability of steel make it ideal for withstanding the harsh conditions of the marine environment, including corrosion from saltwater and extreme weather conditions. Steel coils are used to fabricate various ship parts such as hull plates, bulkheads, decks, and frames, ensuring the structural integrity and safety of the vessel. Additionally, steel coils allow for efficient and cost-effective manufacturing processes, enabling the construction of vessels of different sizes and types to meet the diverse needs of the maritime industry.

- Q: What is steel made of? What are the elements other than iron?

- iron (Fe) and carbon (C). Carbon is in small proportion, from 0.1% to 1.7% or so. If you go over 1.7% carbon by weight you get cast iron, which is much less hard than steel.

- Q: How are steel coils inspected for width?

- Steel coils are inspected for width using various methods to ensure they meet the required specifications. One common method is to use a caliper gauge, also known as a micrometer, which measures the width of the coil by physically contacting its edges. The operator places the caliper gauge at various points along the width of the coil and records the measurements. This method allows for precise measurements and helps identify any inconsistencies or deviations from the desired width. Another method used for inspecting steel coil width is laser measurement. Laser sensors are positioned on both sides of the coil, and they emit a laser beam that scans across the width of the coil. The sensors detect the distance between the coil's edges and provide accurate width measurements. This non-contact method is highly efficient and can quickly inspect the width of the coil without any physical contact or potential damage. In addition to these methods, some advanced systems use computer vision technology for width inspection. Cameras and image processing software are employed to capture images of the coil's edges. The software analyzes these images and calculates the width based on the detected edges. This method allows for high-speed inspections and can detect any irregularities in the width of the coil. Overall, steel coils are inspected for width using a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils meet the required width specifications and help maintain quality control in the steel manufacturing process.

- Q: What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using circular blades to cut the steel coil into narrower strips. Loop slitting involves creating a loop in the steel coil and then cutting it with straight blades. Oscillating slitting uses a reciprocating blade that moves back and forth to cut the coil into smaller widths.

- Q: How are steel coils inspected for dimensional accuracy during processing?

- Steel coils are inspected for dimensional accuracy during processing using various methods such as laser measuring systems, ultrasonic thickness gauges, and calipers. These tools are used to measure the width, thickness, and diameter of the coils to ensure they meet the required specifications. Additionally, visual inspections are also conducted to identify any irregularities or defects in the coils.

- Q: Can steel coils be used in the automotive industry?

- Yes, steel coils can be used in the automotive industry. Steel coils are commonly used in the manufacturing of various automotive components and parts. They are particularly suitable for applications that require high strength and durability, such as body panels, chassis components, suspension parts, and engine components. Steel coils provide excellent structural integrity, corrosion resistance, and impact resistance, which are crucial characteristics for automotive applications. Additionally, steel coils can be easily formed and shaped into the desired dimensions, making them highly versatile and cost-effective for automotive manufacturers. Overall, steel coils are widely utilized in the automotive industry due to their exceptional mechanical properties and suitability for various automotive applications.

- Q: How are steel coils used in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as a primary raw material for constructing the outer body and internal components, such as frames, panels, and structural supports. The steel coils are processed and transformed into various shapes and sizes, ensuring the durability and strength required for appliances.

- Q: How are steel coils cleaned before use?

- Steel coils are typically cleaned before use through a process called pickling, which involves immersing the coils in an acid solution to remove any scale, rust, or other impurities.

- Q: What is the use for spring steel that take advantage of its unique properties?

- *Spring steel is a low alloy, medium carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant bending or twisting. Silicon is the key component to most spring steel alloys. An example of a spring steel used for cars would be AISI 9255 (DIN and UNI: 55Si7, AFNOR 55S7), containing 1.50%-1.80% silicon, 0.70%-1.00% manganese and 0.52%-0.60% carbon. Most spring steels (as used in cars) are hardened and tempered to about 45 Rockwell C. the most widely used spring steel is ASTM A228 (0.80–0.95% carbon), which is also known as music wire. Spring steel is one of the most popular materials used in the fabrication of lock picks due to its pliability and resilience.

Send your message to us

hot rolled PPGI printed steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords