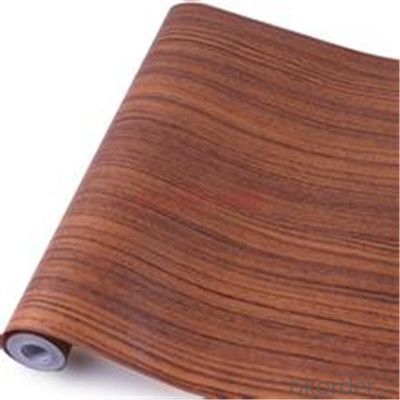

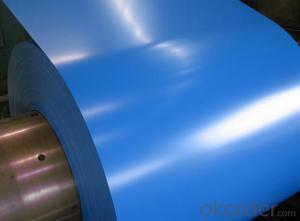

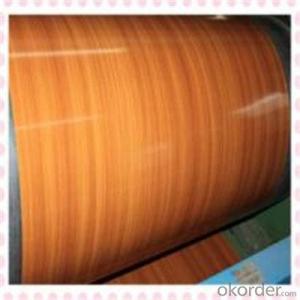

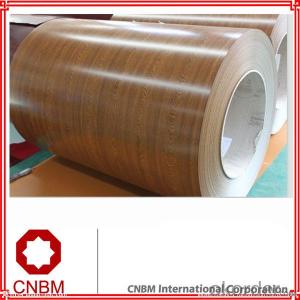

Wood Pattern Printed Prepainted PPGL Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of PPGI:

1. Width: 600~1250mm

2. Thickness: 0.19~1.50mm

3. Grade: JIS G3312-CGCC, CGC340-570, (G550) ASTM A755M CS-B, SS255-SS550

4. Coil Weight: 3~10Mt

5. Coil ID: 508mm/610mm

6. Chemical Treatment: Chromated (Cr 3+, 6+, 0+)

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors, booths, shutters, watch rooms, makeshift houses, street waiting room (booth), refrigerators, etc. |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens, ceilings, toilets, interior elevator lobby, stairwayventilating duct, communication pipelines. |

Specifications of PPGI:

1. PPGI is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for PPGI consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of PPGI can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- steel is a mixture of two or more metal or a metal with non metal to obtain both properties of the indivudual components. carbon steel for example.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- Why Use Stainless Steel Cookware

- Q: What are the challenges faced during steel coil processing?

- Some of the challenges faced during steel coil processing include ensuring proper alignment and feeding of the coils into the machinery, handling the heavy weight and size of the coils, managing the high temperatures involved in processing, preventing surface defects or damage to the steel, maintaining consistent quality throughout the process, and minimizing material waste and scrap.

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: How are steel coils stored in warehouses?

- Steel coils are typically stored in warehouses by stacking them securely on top of each other, either directly on the warehouse floor or on specially designed racks. They are often stored vertically to save space and ensure stability. Additionally, to prevent damage and corrosion, steel coils are often wrapped in protective materials or placed on pallets.

- Q: What is the standard thickness of steel coils?

- The standard thickness of steel coils can vary depending on the specific application and industry requirements. However, in general, steel coils are typically available in a range of thicknesses between 0.5mm to 10mm. The desired thickness of a steel coil is determined by factors such as the intended use, structural requirements, and manufacturing processes. Thicker steel coils are often used for heavy-duty applications that require greater strength and durability, while thinner coils are suitable for lighter applications where flexibility and weight reduction are important. It is important to consult industry standards and specific project requirements to determine the appropriate thickness for steel coils in any given application.

- Q: and what are the four main elements in STAINLESS steel? x

- decreasing the carbon content fabric will strengthen the ductility, which will make it greater versatile. Carbon in metallic varieties brittle cementite (iron carbide) which will strengthen the hardness and capability of metallic.

- Q: How is the demand for steel coils influenced by the construction sector?

- The demand for steel coils is heavily influenced by the construction sector. Steel coils are a vital component in the construction industry as they are used for a wide range of applications such as structural framework, roofing, fencing, and reinforcement. The construction sector's demand for steel coils is driven by various factors. Firstly, as the construction industry experiences growth and expansion, there is an increased need for steel coils to meet the rising demand for new infrastructure, commercial buildings, and residential properties. This includes the construction of bridges, highways, airports, office complexes, residential towers, and more. Secondly, the construction sector's demand for steel coils is influenced by economic conditions. When the economy is performing well and there is increased investment in construction projects, the demand for steel coils tends to rise. Conversely, during economic downturns or recessions, the construction sector slows down, leading to a decrease in demand for steel coils. Additionally, technological advancements and changes in construction techniques also influence the demand for steel coils. As new construction methods and materials are introduced, the use of steel coils may increase or decrease depending on their compatibility and effectiveness in these new applications. For example, the use of pre-engineered steel buildings has gained popularity, increasing the demand for steel coils. Moreover, government policies and regulations play a crucial role in shaping the demand for steel coils in the construction sector. Government initiatives promoting infrastructure development, sustainable construction practices, or energy-efficient buildings can significantly impact the demand for steel coils. For instance, incentives for green buildings may drive the use of steel coils in construction projects aiming for LEED certification. In conclusion, the demand for steel coils is closely tied to the construction sector. Economic conditions, construction activity, technological advancements, and government policies all influence the demand for steel coils in the construction industry. Understanding these factors is essential for steel manufacturers and suppliers to effectively meet the needs of the construction sector.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include the increasing demand for high-strength steel coils due to their durability and lightweight properties. There is also a growing focus on sustainability and environmentally friendly practices, leading to the development of eco-friendly coatings and recycling initiatives. Additionally, digitalization and automation are becoming more prevalent, enhancing efficiency and productivity in steel coil manufacturing processes.

- Q: I want to make a stock removal knife, but I am really confused about what steel to use. I am just a beginner but I read o1 steel is great? Also I am kind of on a budget.

- 01 tool steel is easier to work with. You need to contact places like Pop Knives and Supplies out of Washington, Georgia or Sheffield Steel out of Florida, I made custom knives for years with my husband. Made alot with ATS-34 Stainless. Look at links on my website source.

Send your message to us

Wood Pattern Printed Prepainted PPGL Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords