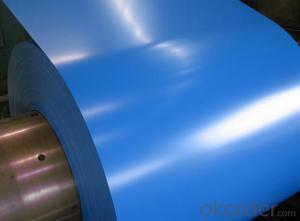

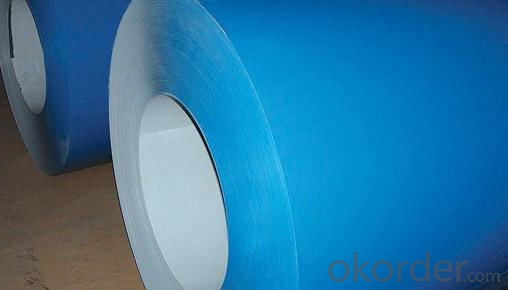

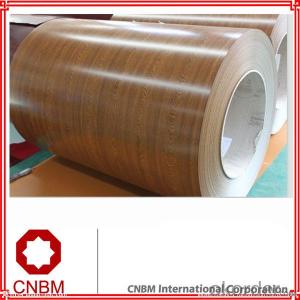

PPGL-PRE-PAINTED GALVALUME STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

PPGL PREAINTED GALVALUME STEEL SHEET IN COIL ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- no it is not, he made that up steel is a conductor and can't build static electricity. Compass needle is a magnet and as such was attracted to steel .

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils are different from regular steel coils as they are coated with a layer of zinc to prevent corrosion and rust formation. This zinc coating acts as a protective barrier, increasing the longevity and durability of the steel coils, especially in harsh environmental conditions.

- Q: many sword sellers sell swords made of 440 and stainless, i know those are both totally **** for real swords. so are 1045, 1060, or 1095 good grades of steel for a sword?

- Carbon Steel is the most common, while most live-steel(designed for use) ready sword utilize on of the spring steels you mentioned. Hybrid steel like those used in the Slayer series seem neigh-indestructible. The steel should be strong enough to not notch on a strike, but flexible enough to flex when you bend it, lest it shatter on a hard blow.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- Pedal steel guitars are a challenge to learn but they're a great instrument. More, even a starter pedal steel is going to run you $800 or so. Elderly Instruments in Lansing, Michigan sells a Carter brand starter pedal steel for $795 which is about as low as I've seen new ones. It has 3 foot pedals and 4 knee levers so it's nicely equipped. From northern Indiana it's not that far I would think. Good luck.

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: How do steel coils contribute to the circular economy?

- Steel coils contribute to the circular economy through their recyclability and reusability. The circular economy aims to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. Firstly, steel coils are made from recycled steel, which reduces the need for extracting raw materials and the associated environmental impact. By using recycled steel, we can conserve natural resources and reduce energy consumption during the manufacturing process. This practice helps to lower carbon emissions and decrease the overall ecological footprint. Furthermore, steel coils can be easily recycled at the end of their lifecycle. Steel is one of the most recycled materials globally, with a high recycling rate. When the coils reach the end of their use, they can be collected, processed, and transformed into new steel products, without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, minimizing the need for virgin steel production. Additionally, steel coils support the circular economy by enabling the creation of durable and long-lasting products. Steel is known for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can produce products that have a longer lifespan, reducing the need for frequent replacements and minimizing waste generation. Moreover, steel coils can be reused multiple times before they are recycled. They can be rewound, reshaped, or repurposed for different applications, extending their lifecycle and reducing the demand for new coils. This reuse aspect of steel coils contributes to resource efficiency and waste reduction. In summary, steel coils play a significant role in the circular economy by being made from recycled steel, being easily recyclable themselves, enabling the creation of durable products, and promoting reuse. Their contribution helps to close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Does it say stainless steel on it?

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils used in the structural component industry can vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can vary but is often around 2000 to 2500 meters.

- Q: What are the key players in the steel coil manufacturing industry?

- Large multinational companies with significant market share and influence dominate the steel coil manufacturing industry. Among the prominent players are: 1. ArcelorMittal, the world's largest steel producer, operates in over 60 countries and offers a diverse product portfolio. 2. Nippon Steel Corporation, a leading Japanese steelmaker, holds a prominent position in the global steel coil manufacturing market, particularly in the automotive and construction sectors. 3. POSCO, based in South Korea, is renowned for its high-quality steel products and advanced technology in steel coil manufacturing. 4. Baosteel Group Corporation, the largest steel manufacturer in China and globally, boasts a vast range of steel products, including steel coils, and excels in research and development capabilities. 5. Thyssenkrupp AG, a German multinational conglomerate, plays a significant role in the steel coil manufacturing industry, focusing on innovation and sustainability across a diverse product range. 6. United States Steel Corporation, a leading American steel producer, holds a crucial position in the steel coil manufacturing industry, particularly in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc., a Japanese steel conglomerate, is a key player in the steel coil manufacturing industry, known for its customer-oriented approach and high-quality steel products. These companies represent a fraction of the key players in the steel coil manufacturing industry, as numerous others contribute to this sector. The industry is highly competitive, and these companies consistently strive to innovate, enhance efficiency, and meet the evolving demands of the market.

- Q: Can steel coils be stretched?

- No, steel coils cannot be stretched as they are already tightly wound and have limited flexibility.

Send your message to us

PPGL-PRE-PAINTED GALVALUME STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords