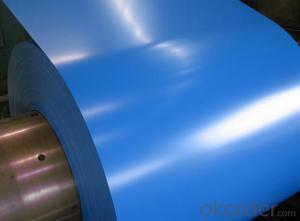

PPGL/Color Steel Coil/Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:ASTM, JIS, GB, AISI, DIN, BS

Surface Treatment:Alu-Zin Coating

Certification:ISO, SGS, BV, RoHS, IBR

Technique:Hot Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Roof Building Construction

Edge:Slit edge

Stock:Stock

Steel Grade:Q235

Thickness:0.16-0.8mm

Width:914/1000/1200/1219/1220/1250mm

Al-Zinc Coating:Az50-150G/M2

Spangle:Regular Spangle

Surface Printing:Can Be Used The Base Material of PPGL

Export Markets:Global

Additional Info.

Packing:Export High-Accuracy Package

Standard:0.45*1219*C

Origin:China

HS Code:72104900

Production Capacity:30000mt

Product Description

Specification :

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um5. Gloss: Normal or High gloss

6. Alume Zinc coating: AZ50-AZ275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

| Commodity | Hot Dip Alu-zinc Steel Coils |

| Techinical Standard: | ASTM A792 |

| Grade | TDX51D+AZ, SGLCC |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Thickness | 0.18-1.0mm |

| Width | 914/1000/1200/1219/1220/1250mm |

| Type of coating: | galvalume (AL-zinc) |

| Zinc coating | AZ50-150g/m2 |

| Surface treament | chromed with passivation / environmental chromed |

| oiled/slightly oiled/ dry/not anti-fingerprint/ skinpassed | |

| Zincalume with protection film (35 µ , Nominal Adhesion 265 gr/ 50mm) | |

| Based metal: Steel Sheet, 55% Aluminum-Zinc alloy coated in Coils | |

| ID coil | 508mm or 610mm |

| MIQ | minimum 25 MT for each size |

| Supply capacity: | 1000MT per month |

| Package: | Properly packed for ocean freight exportation in containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test | |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wound around a laminated steel core to create an electromagnet that generates the magnetic field required for the motor's operation. The steel coils, when energized with electric current, produce a magnetic field that interacts with the stator and rotor to facilitate the conversion of electrical energy into mechanical energy.

- Q: What metals contain steel? It can be anything except soft iron or steel.

- Metals do not contain steel. Steel is an alloy of purified iron and carbon, and sometimes with other metals, such as nickel, chromium, or molybdenum to make it stainless or to change its hardness or other properties. It's like asking what cereals contain Cheerios. It doesn't really make sense. Other metal alloys contain iron, which is an element and the main ingredient of steel. Maybe you should be asking which metal alloys contain iron? That's more like asking which cereals contain whole grain oats. Now that's a question that can be answered by reading the ingredients labels on your standard boxes of metal alloys :-)

- Q: Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This is commonly achieved through various coating techniques like painting, powder coating, or laminating, which can add aesthetic appeal to the steel coils while enhancing their overall appearance and functionality.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- It is still the same for 1008 steel. Go to the bottom and see the listing of the grades it covers. Since the only difference between the 1006 and 1008 steel is a few micro amounts of alloys and by far the greatest majority or main component is iron (99%), as a general melt temperature , 2750 F is the melt temperature at which the other alloys are added to the charge to fine tune the mix. Just like adding salt to distilled water actually lowers the boiling point of water, adding alloys to iron decreases the melting point of iron. The iron melts at 2800F, but once alloys to make the 1008 grade are added, it decreases melt temp to 2750F. Since the melting point of pure iron is 2800F, the temperature is actually decreased by adding these impurities of alloys. These alloys are tested while the mix is starting to come down from a pure melt, steel is sampled. and then alloys below are checked and added to make the 1008 steel. The steel is maintained at 2750 F so that the less volatile alloys don't boil off before combining with steel. Minimum Properties Ultimate Tensile Strength, psi 43,900 - 51,900 Yield Strength, psi 26,100 - 34,800 Elongation 42 - 48% Chemistry Iron (Fe) 99% Carbon (C) 0.08% Manganese (Mn) 0.6% max Phosphorus (P) 0.035% max Copper (Cu) 0.2% min Sulfur (S) 0.04%

- Q: Maybe it is obvious. But i have thought alot about it.I thought steel at a cool temperature was unbreakable. I am not one for science or physics or engineering (i am a political science major). But i don't understand why the planes that struck the world trade center on 9-11 didn't just dent the side and fall,How did the place break the steel? Was it the velocity? Is steel easily broken?I realized that i wasn't taught how the planes broke the steel, and that no one ever asked. I searched the web and i couldn't find the answer or even anyone who had asked the question before.(i don't care about conspiracy theories, i just want scientific facts)

- I saw a one-hour program about this on PBS a couple of years ago. The buildings were constructed with the concrete-clad steel supporting columns at the center of the buildings, with a relatively thin lattice of steel struts along the outer wall. When the planes hit, they sheered through the thin steel struts easily by sheer momentum, while, at the same time, the thin steel stripped off the wings. The bodies of the planes got as far as the supporting columns in the center of the buildings, but were stopped there. The heaviest, densest pieces, the engines, went completely through the buildings and popped out the other side. It's important to understand that even light materials can cut through metal, if the light material is going fast enough. I saw this first hand, when I was in the Navy and stationed on board ship. We had a helicopter crash on our flight deck during heavy weather. The blades were made of light, carbon-composite material, but they were going so fast that they cut through the aluminum deck. I still have photos of that damage.

- Q: What are the different methods of surface treatment for steel coils?

- Steel coils can undergo various surface treatment methods, each with its own advantages and uses. Some commonly employed techniques include: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc results in a protective coating. This process offers excellent corrosion resistance and is commonly employed in outdoor applications like roofing, fencing, and automotive parts. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coil's surface. Electro-galvanizing provides similar corrosion resistance to hot-dip galvanizing but with a thinner coating. It is often utilized when a smooth and visually appealing finish is desired, such as in appliances, electrical equipment, and automotive components. 3. Powder coating: A dry powder is applied to the steel coil's surface and cured under heat to form a durable and protective layer. This method offers excellent resistance to chipping, scratching, and fading, making it suitable for both indoor and outdoor applications. 4. Painting: Liquid paint coatings can be applied to steel coils, offering both protection and aesthetic appeal. These coatings can be customized to meet specific requirements such as corrosion resistance, UV protection, or chemical resistance. They find common usage in industries like construction, automotive, and appliances. 5. Pickling and oiling: This method involves removing scale or rust from the steel coil's surface by dipping it in an acid solution (pickling), followed by a coating of oil to prevent reoxidation. Pickling and oiling are typically employed for temporary corrosion protection during the storage and transportation of steel coils. 6. Pre-painted coatings: Steel coils can be coated with pre-painted finishes during the manufacturing stage. This continuous process involves passing the steel coil through a coating line where a layer of paint is applied. Pre-painted coatings offer a wide range of colors and finishes, making them popular in industries like construction, automotive, and appliances. These are only a few examples of the surface treatment methods commonly used for steel coils. The selection of a specific technique depends on factors such as desired corrosion resistance, aesthetic preferences, environmental conditions, and specific application requirements.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- D2 and O2 steels are nice. They are expensive, but hold an edge extremely well. S30V is nice also. It's a more stain-resistant steel that holds an edge very well. For outdoor hiking/camping knives, it's tough to beat good old 1095 carbon steel. Sure it will rust, but it's tough as nails, not brittle, holds an edge pretty well, and easy to sharpen...and it's pretty cheap. Other steels, AUS8 is an ok cheap steel. It's stain resistant and cheap. AUS6 isn't worth the time or effort. Buck knives does an excellent job of heat treating 420 stainless to become very hard. Their knives are excellent considering 420 stainless is typically soft steel.

- Q: Can steel coils be customized?

- Yes, steel coils can be customized to meet specific requirements such as size, shape, thickness, and surface finish. Customization can be done through processes like cutting, slitting, shaping, and coating to ensure that the steel coils are tailored to the desired specifications.

- Q: How are steel coils used in the production of agricultural machinery parts?

- Due to their strength and versatility, steel coils find common usage in the manufacturing of agricultural machinery parts. Materials chosen for agricultural machinery parts, like blades, plowshares, and cultivator tines, must possess durability and the ability to withstand harsh conditions. Steel coils effectively meet these requirements, providing the necessary strength and durability for such parts. The process commences with the unwinding and cutting of the steel coils into desired lengths. These lengths are then fed into a machine where they undergo a series of shaping processes, including bending, cutting, and stamping. These shaping processes enable the steel to be molded into the precise shapes demanded by agricultural machinery parts. Upon achieving the desired shape, it is often customary to subject the steel parts to heat treatment in order to enhance their strength and durability. Heat treatment involves subjecting the parts to high temperatures, followed by rapid cooling. This treatment significantly elevates the steel's hardness and toughness, rendering it more resistant to wear and tear experienced in the agricultural field. Following the heat treatment, the steel parts may undergo additional processes, such as welding, surface coating, or painting, depending on the specific requirements of the machinery. These additional processes further enhance the durability and longevity of the parts. In conclusion, the significance of steel coils in the production of agricultural machinery parts cannot be overstated, as they ensure the provision of requisite strength, durability, and versatility. The utilization of steel coils guarantees that these parts can effectively endure the demanding conditions encountered in agricultural operations, ultimately contributing to the efficiency and productivity of the farming industry.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- *Carbon steel, also called plain carbon steel or Mild Steel, is steel where the main alloying constituent is carbon. The AISI defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. If it crosses limit as said, it will come under alloy steel. ASTM A 106 gr B is a carbon steel pipe and seamless Pipe for High Temperature Service. So, it will be a mild steel comes under carbon steel category.

Send your message to us

PPGL/Color Steel Coil/Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords