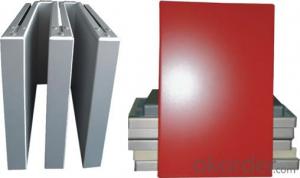

Wood Grain Coated Square Aluminum Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

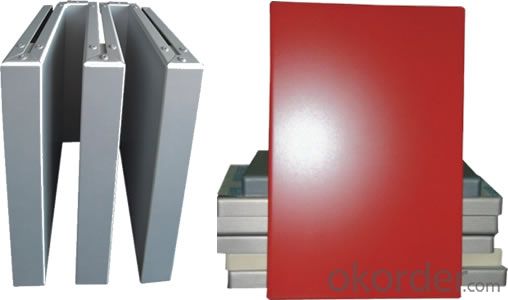

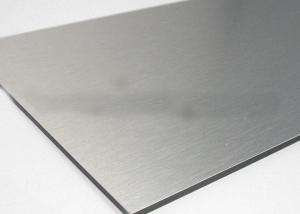

Coated Square Aluminium Panel

Specifications:

Alloy:1xxx,3xxx,8xxx series

Temper: O,F,H111,H112,H12,H14,H16,H18,H22,H24,H26 etc.

Thickness: 0.2mm-150mm

Width: 500mm-2800mm

Length: 500mm-10000mm

Tensile Strength: 110 to 170 MPa

Elongation: >=2%

Standard dimensions: 1219x2438mm, 48''x96''

ISO9001, SGS passed

Competitive price

Professional producing & exporting experience

All kinds of Alloy and size are available

Coated Square Aluminium Panel

Specifications:

Alloy:1xxx,3xxx,8xxx series

Temper: O,F,H111,H112,H12,H14,H16,H18,H22,H24,H26 etc.

Thickness: 0.2mm-150mm

Width: 500mm-2800mm

Length: 500mm-10000mm

Tensile Strength: 110 to 170 MPa

Elongation: >=2%

Standard dimensions: 1219x2438mm, 48''x96''

ISO9001, SGS passed

Competitive price

Professional producing & exporting experience

All kinds of Alloy and size are available

- Q: What are the fire resistance properties of aluminum coils?

- Aluminum coils have excellent fire resistance properties due to the unique characteristics of the metal. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which allows it to withstand high temperatures without deforming or melting. In addition, aluminum forms a thin layer of oxide on its surface when exposed to air, which acts as a protective barrier against fire and prevents further oxidation. This oxide layer has a high melting point and is non-combustible, making it an effective fire retardant. Furthermore, aluminum is a poor conductor of heat, meaning it does not readily transfer heat during a fire, which helps to slow down the spread of flames. Therefore, aluminum coils are widely used in various applications where fire resistance is a crucial requirement, such as in building construction, transportation, and electrical wiring.

- Q: What are the different packaging weights available for aluminum coils?

- The available packaging weights for aluminum coils vary depending on specific requirements and applications. Aluminum coils can be packaged in a range of weights, typically measured in pounds or kilograms. The specific packaging weight depends on factors such as coil size, thickness, and the quantity needed by the customer or industry standards. For larger industrial applications, common packaging weights for aluminum coils can range from as low as 500 pounds (or 227 kilograms) to several thousand pounds (or several metric tons). These weights guarantee secure and efficient transportation and storage, as well as easy handling and loading. It is worth mentioning that the packaging weight of aluminum coils can be customized to meet specific needs. Manufacturers and suppliers often collaborate closely with customers to determine the most suitable packaging weight based on transportation requirements, storage space limitations, and industry regulations. In conclusion, the packaging weights for aluminum coils are flexible and can be personalized to meet individual needs, ensuring safe and convenient handling while satisfying the demands of different industries.

- Q: This question asks for the cost of an aluminum coil, which can vary based on factors such as weight, quality, and market conditions.

- <p>The cost of an aluminum coil can vary significantly based on its weight, grade, and current market prices. As of my last update, the price per pound can range from about $0.30 to $1.50, but this is subject to change with market fluctuations. For precise pricing, it's best to check with a supplier or on a commodity exchange, as aluminum prices are dynamic and influenced by global supply and demand.</p>

- Q: How long do aluminum coils last?

- The lifespan of aluminum coils can vary depending on various factors such as usage, maintenance, and environmental conditions. However, on average, well-maintained aluminum coils can last anywhere between 15 to 20 years.

- Q: Are aluminum coils suitable for food processing applications?

- Yes, aluminum coils are suitable for food processing applications. Aluminum is a non-toxic and corrosion-resistant material, making it safe for direct contact with food. It also has excellent heat conductivity, allowing for efficient heating and cooling processes in food processing. Additionally, aluminum coils are easy to clean and maintain, making them a popular choice in the food industry.

- Q: How do aluminum coils withstand extreme weather conditions?

- Aluminum coils are designed to withstand extreme weather conditions due to their inherent properties and construction. The aluminum used in these coils is highly resistant to corrosion, allowing them to endure exposure to moisture, rain, snow, and even saltwater without deteriorating. Additionally, aluminum coils have excellent heat transfer capabilities, enabling them to dissipate excessive heat and prevent damage from high temperatures. Moreover, they are sturdy and durable, enabling them to withstand strong winds, heavy storms, and even hail. Overall, the combination of corrosion resistance, heat transfer efficiency, and robust construction make aluminum coils well-equipped to endure harsh weather conditions.

- Q: This question asks for guidelines on safely transporting aluminum coils, which are large and heavy metal rolls used in various industries.

- <p>To transport aluminum coils safely, follow these steps: Use specialized vehicles with proper securing mechanisms to handle the weight and prevent rolling. Ensure the coils are balanced and secured with straps or chains to avoid shifting during transit. Maintain a steady speed to minimize vibrations that could cause damage. Avoid sudden stops or sharp turns. Keep the load covered to protect from moisture and dirt. Adhere to all legal weight and dimension limits for your route. Regularly inspect the vehicle and load for any signs of damage or instability. Always follow local transportation regulations and safety guidelines.</p>

- Q: Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes through various processes such as bending, rolling, or stamping.

- Q: Is it possible to utilize a grinder for cutting aluminum coils?

- <p>Yes, you can use a grinder to cut aluminum coils, but it's important to use the right type of grinder and accessories. An angle grinder with a cutting wheel or a metal cutting disc is suitable for this task. Ensure the grinder is equipped with a safety guard and that you're wearing appropriate safety gear, such as goggles and gloves. Be cautious as aluminum can be slippery and the grinder can generate a lot of heat, which may require frequent cooling to prevent the disc from burning out. It's also advisable to work in a well-ventilated area due to the fine particles produced during cutting.</p>

Send your message to us

Wood Grain Coated Square Aluminum Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords