Wood Framed Aluminum Tin Sheets - Structural Framing and Machined Components Aluminum Sheet 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Structural Framing and Machined Components Aluminum Description:

Structural Framing and Machined Components Aluminum is for Construction material with good ductility, polishing ability and corrosion resistance, good electrolytic oxidation, suitable for welding. Have good plasticity qualities in an annealed state suitable when hardened. Very good corrosion resistance, this material is not inclined to stress corrosion cracking. Cutting tool workability in an annealed state is not suitable but is acceptable in a hardened temper. Used for medium strength components with long operation schedules in temperatures from 50°C up to 70°C, applications requiring specific technological properties, corrosion resistance, aesthetic features, when in contact with food, high specification aviation and automotive components. Typical product applications include: airplane cabins, helicopter cockpits, floor coverings, door frames, safety barriers, escalators, furniture, rivet stems, cranes and columns.

2.Main Features of Structural Framing and M achined Components Aluminum:

Good Ductility

Polishing Ability

Corrosion Resistance

Competitive Price

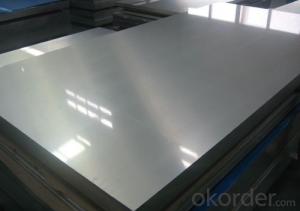

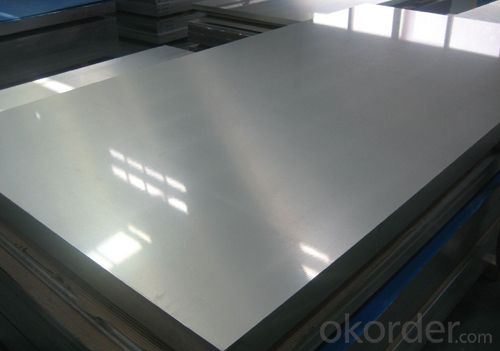

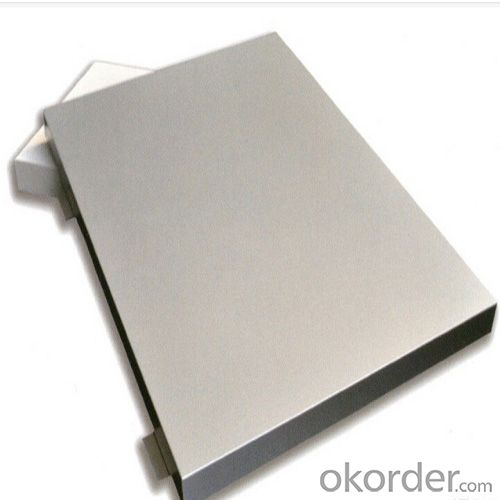

3. Structural Framing and Machined Components Aluminum Images:

4. Structural Framing and Machined Components Aluminum Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 3-12mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 10 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

- Q: Can aluminum sheet be used for aerospace structural components?

- Certainly, aerospace structural components can indeed utilize aluminum sheet. In the aerospace industry, aluminum is widely employed owing to its advantageous characteristics, including a high strength-to-weight ratio, resistance to corrosion, and excellent formability. By using aluminum sheet for these structural components, it becomes possible to construct aircraft that are lightweight, a crucial factor for optimizing fuel efficiency and performance. Moreover, aluminum is readily accessible and cost-effective, making it a favored option for aerospace applications. Nevertheless, it is worth mentioning that the selection of the aluminum sheet's specific grade and thickness will depend on the precise requirements and specifications of the aerospace structural component.

- Q: Are aluminum sheets suitable for aerospace wing structures?

- Yes, aluminum sheets are suitable for aerospace wing structures. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and its ability to withstand high temperatures. Aluminum alloys, such as 2024 and 7075, are commonly used for wing structures as they provide high strength and durability. Additionally, aluminum can be easily formed into different shapes and sizes, allowing for the production of complex wing designs. Overall, aluminum sheets offer a combination of lightweight properties, strength, and reliability, making them highly suitable for aerospace wing structures.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and durable material that has excellent corrosion resistance properties, making it suitable for ventilation applications. It can be easily formed and fabricated into various shapes and sizes, allowing for the customization of ventilation components. Additionally, aluminum is a good conductor of heat, which can be beneficial for HVAC systems that require efficient heat transfer.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can be an alternative to wood in certain applications. Aluminum sheets have several advantages over wood, including being lightweight, durable, and resistant to corrosion and fire. They can be used in various industries such as construction, automotive, aerospace, and marine, where wood may not be suitable due to its limitations. However, the selection of material depends on the specific requirements of the application and the desired properties needed.

- Q: Can aluminum sheets be anodized?

- Yes, aluminum sheets can be anodized. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer enhances the metal's corrosion resistance, durability, and appearance. Anodizing is commonly used in various industries such as automotive, aerospace, and construction to provide a protective coating and improve the aesthetics of aluminum sheets. The process involves immersing the aluminum sheet in an acid electrolyte solution and passing an electric current through it, causing oxygen ions to bond with the aluminum atoms and form the oxide layer. This layer can be further enhanced with the addition of dyes or pigments to create different colors and finishes. Overall, anodizing is a versatile and effective method for treating aluminum sheets.

- Q: Can aluminum sheets be used for water tanks?

- Water tanks can indeed utilize aluminum sheets. Thanks to its lightweight nature and resistance to corrosion, aluminum is an ideal material for water storage. Its durability and ability to fend off rust and corrosion have made it a popular choice in industries like aerospace and marine. Furthermore, aluminum tanks are simpler to transport and install in comparison to alternative materials, and they can endure high pressure and extreme temperatures. Nonetheless, it is crucial to guarantee that the aluminum sheets employed for water tanks are of exceptional quality and adhere to the required standards to uphold the tank's safety and longevity.

- Q: Are 101 aluminum sheets resistant to UV radiation?

- Yes, 101 aluminum sheets are generally resistant to UV radiation.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q: Are 101 aluminum sheets suitable for food-grade applications?

- Yes, 101 aluminum sheets are suitable for food-grade applications. 101 aluminum is a commercially pure alloy with excellent corrosion resistance and good formability. It has a low chemical reactivity, which means it does not react with acidic or alkaline foods, making it safe for use in food-grade applications. Additionally, 101 aluminum sheets can be easily cleaned and sanitized, making them an ideal choice for food processing, packaging, and storage.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

Send your message to us

Wood Framed Aluminum Tin Sheets - Structural Framing and Machined Components Aluminum Sheet 6061

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords