Wholesale Painted Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

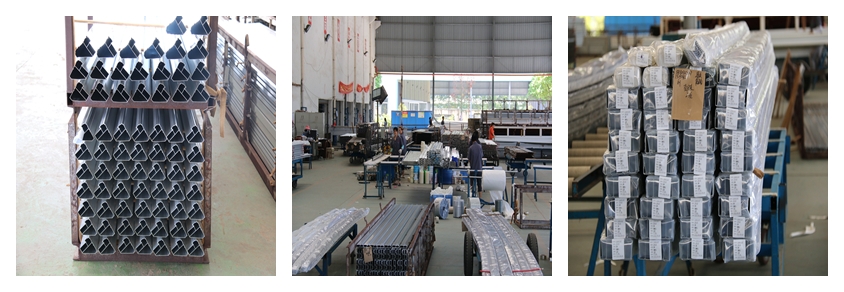

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Can 101 aluminum sheets be used in the production of consumer electronics?

- Yes, 101 aluminum sheets can be used in the production of consumer electronics. Aluminum is a versatile and lightweight material that is commonly used in the manufacturing of various electronic devices such as smartphones, laptops, tablets, and other consumer electronic products. It offers excellent thermal conductivity, corrosion resistance, and electrical conductivity properties, making it suitable for use in electronics. The specific grade of aluminum, such as 101, may have different characteristics that make it suitable for different applications. However, without more information about the specific requirements of the consumer electronics being produced, it is difficult to determine if 101 aluminum sheets are the most appropriate choice.

- Q: Can aluminum sheets be embossed or engraved?

- Yes, aluminum sheets can be embossed or engraved.

- Q: How do you prevent warping of aluminum sheets during machining?

- There are several measures that can be taken to prevent warping of aluminum sheets during machining: 1. Proper material selection is crucial in minimizing warping. Opt for aluminum alloys with lower levels of thermal expansion, like 6061 or 7075, as they are less prone to warping. 2. It is recommended to stabilize the material before machining by annealing or stress-relieving the aluminum sheets. This process reduces internal stresses and decreases the likelihood of warping. 3. Ensure the use of appropriate cutting tools. Opt for tools with sharp edges and proper geometry to minimize heat generation and facilitate efficient chip removal. Carbide or diamond-coated tools are often preferred for their high heat resistance when machining aluminum. 4. Minimize heat generation during machining, as excessive heat can cause warping. Implement the use of coolant or lubricants to reduce friction and dissipate heat. Continuous cooling helps maintain a stable temperature and prevents warping. 5. Properly control cutting parameters such as cutting speed, feed rate, and depth of cut to prevent warping. High cutting speeds or excessive material removal rates generate excessive heat, which leads to warping. Experimentation and experience should determine the optimal parameters. 6. Use appropriate fixturing during machining to minimize the chances of warping. Securely clamp the aluminum sheets using suitable fixtures or jigs to maintain stability and prevent movement. 7. Consider employing machining techniques like climb milling or ramping, which reduce vibrations and ensure a smoother cutting process, thereby reducing the risk of warping. 8. After machining, it is advisable to stress-relieve the aluminum sheets again. This step further reduces any residual stress that may have developed during the machining process. By adhering to these steps, the chances of warping during the machining of aluminum sheets can be significantly reduced, resulting in high-quality finished products.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes due to their malleability and ductility.

- Q: 8mm which type of aluminum plate is suitable for bending?

- Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Copper Aluminum Alloy

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- aluminum okorder / so what you are finding is that aluminum will melt before the copper or brass...

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- How strong aluminum is, depends on the specific alloy of aluminum, whether it is the aluminum 1000 series, or the 3000 series, or the 6000 series, or other variants. The 6000 series is most common for structural purposes. Do a search on its yield strength and its ultimate tensile strength, to get an idea of how strong your particular variant is. The alloy Aluminum 6061-T6 has a yield strength of 35000 lb/in^2, and an ultimate tensile strength of 42000 lb/in^2. This is for the case of pure tension with a uniform load. The square inches refers to its cross sectional area. The ultimate strength occurs at the point where it will completely rupture. The yield strength occurs at the point, where it still supports the load, but ceases to be reversible after the load is removed. Pure aluminum metal is much weaker than its alloys. It has a yield strength of about 1500 psi, and an ultimate strength of 10000 psi. For structural purposes, you almost always want to stay below the yield strength. How stiff aluminum is, is common among all alloys, as 10000000 psi. That is to say 10 million pounds of tension on an aluminum member with a cross sectional area of 1 inch, would hypothetically cause an increase equal to 1 length, if it were still in-tact and linear-elastic at that amount of stress. It isn't. A more realistic case, would be that 10000 pounds of tension on this member, would cause an 0.1% increase in length. As for how light aluminum is per square inch, that depends upon how long your rod is. A 3 ft rod weighs 3 times as much per square inch as does a 1 ft rod. The weight of a material is measured PER UNIT VOLUME rather than per unit area. Unless you are talking about a standard thickness. Aluminum 6061 alloys have a density of 0.0975 pounds/cubic inch. Pure aluminum has a this density as well, as do most of its alloys.

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, it is important to apply a protective coating or finish to the surface. This can include using clear lacquer or anodizing the aluminum, which creates a durable oxide layer that resists corrosion and discoloration. Regular cleaning and maintenance, avoiding harsh chemicals, and protecting the aluminum from exposure to extreme temperatures can also help prevent discoloration.

- Q: Is it possible for an individual to install their own aluminum sheet roofing?

- <p>Yes, you can install your own aluminum sheets roof, but it requires some skills and knowledge. You'll need to measure and cut the sheets accurately, secure them properly, and ensure watertight installation. It's advisable to have experience in roofing or construction, or to follow detailed instructions and safety precautions. For complex roofs or if you're unsure, hiring a professional is recommended to avoid damage or injury.</p>

Send your message to us

Wholesale Painted Aluminum Sheets - Aluminum Sheet 1050 3003 1060 1100 3mm 6mm 1.15mm 2mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords