Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

1. Detailed Specifications:

| Product | Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

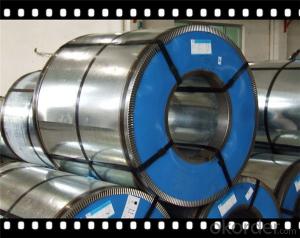

3. Image:

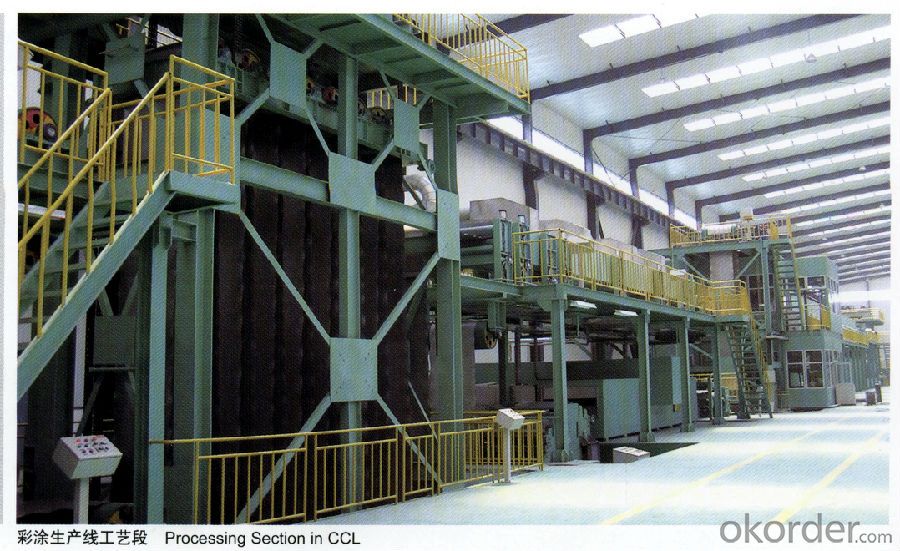

production Line:

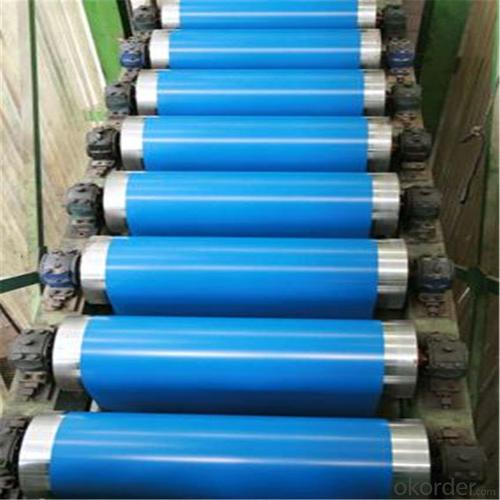

production show:

4.Packaging & Delivery

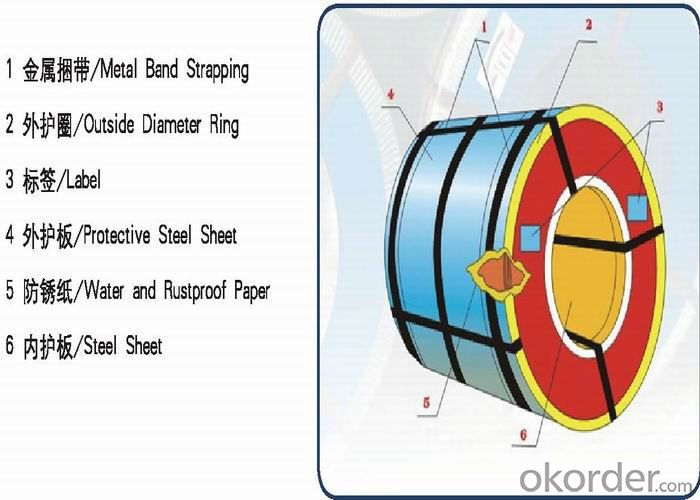

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q: How are steel coils used in the manufacturing of storage shelves?

- Steel coils are used in the manufacturing of storage shelves by being cut and shaped into the desired size and design. The coils are typically processed through a roll forming machine which bends and molds the steel into the required shape for the shelves. This process allows for high efficiency and precision in creating uniform and durable storage shelves.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: How are steel coils inspected for elongation using elongation testers?

- Elongation testers are utilized to inspect steel coils for elongation, following a specific procedure. Initially, a representative sample is extracted from the steel coil, which is then prepared for testing by cutting it into a specific size and shape. Typically, the sample takes the form of a flat strip. Next, the prepared sample is inserted into the elongation tester, which comprises two clamps. One end of the sample is securely held in one clamp, while the other end is held in the other clamp. These clamps are designed to prevent any slippage during the testing process. Once the sample is securely clamped, the elongation tester applies a gradually increasing tensile force to the sample. Consequently, the sample elongates. During this elongation, the tester measures the change in length using a precision measuring instrument, like a strain gauge or an extensometer. The elongation tester records the original length of the sample before the test and continuously measures the length as the force is applied. To calculate the elongation percentage, the original length is subtracted from the final length of the sample, which is then divided by the original length. The obtained elongation value is then compared to the elongation requirements specified by industry standards or customer specifications. If the elongation falls within the acceptable range, the steel coil is considered to have passed the elongation test. On the other hand, if the elongation value exceeds the allowable limits, the steel coil might be rejected or undergo further investigation to determine the cause of elongation. Overall, the process of inspecting steel coils for elongation using elongation testers involves sampling, secure clamping, application of tensile force, length measurement, and elongation percentage calculation. This ensures that the steel coils meet the desired standards and requirements, guaranteeing their quality and mechanical properties.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- There is going to be too much stress at that mounting point for jb to work for long, unless you plan on never leaning more than 5 degrees from prostrate. Buy a new or used one. They are cheap if your not too picky. If you do plan on using jb, i highly recommend drilling multiple 1/8 or so holes on both sides of the crack, and smash some jb into those holes as you patch it. That will allow the jb to hold on much better.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped. Steel coils are highly flexible and can undergo various bending and shaping processes to achieve desired forms and configurations.

- Q: What are the different types of steel coil handling attachments?

- Some of the different types of steel coil handling attachments include coil lifters, coil grabs, coil hooks, coil tongs, and coil C-hooks. These attachments are designed to safely lift, transport, and manipulate steel coils of various sizes and weights.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How are steel coils used in the production of pipes and tubes?

- Steel coils are used in the production of pipes and tubes by being fed into a pipe or tube mill, where they are unraveled, formed, and welded together to create the desired size and shape of the pipe or tube.

- Q: How do steel coil manufacturers ensure fair pricing?

- Steel coil manufacturers ensure fair pricing through various measures. Firstly, they conduct thorough market research to understand the current industry trends, demand-supply dynamics, and competitor pricing. This helps them determine a competitive yet fair pricing strategy that aligns with market standards. Secondly, steel coil manufacturers consider the cost of raw materials, production, and operational expenses to determine a reasonable base price. They also factor in economies of scale, as larger production volumes can lead to lower costs per unit. Additionally, steel coil manufacturers often establish long-term partnerships with suppliers to ensure a stable and consistent supply of raw materials at fair prices. This allows them to maintain a reasonable cost structure and minimize price fluctuations. Furthermore, these manufacturers strive for transparency in pricing by providing detailed quotations that break down the cost components. This helps customers understand the factors contributing to the final price and ensures fairness in the pricing process. To enhance fairness, steel coil manufacturers also consider the specific requirements of their customers. They may offer customized pricing based on factors such as order volume, delivery timelines, and value-added services. This approach ensures that each customer receives a price that is commensurate with their unique needs and requirements. Overall, steel coil manufacturers ensure fair pricing by conducting market research, considering cost factors, maintaining transparent pricing practices, and offering customized pricing options. By doing so, they aim to create a fair and mutually beneficial pricing environment for both themselves and their customers.

- Q: What is the use for spring steel that take advantage of its unique properties?

- The primary use is for springs. It can be deflected to a large extent by applying a force it will return to its original shape when the force is removed. The force/displacement relationship tends to be a constant. A lesser use is to use spring steel wire as a vibrating string on a stringed instrument.

Send your message to us

Wholesale Galvanized PPGI Zinc Coating30-150GSM/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords